Product Description

Product Description

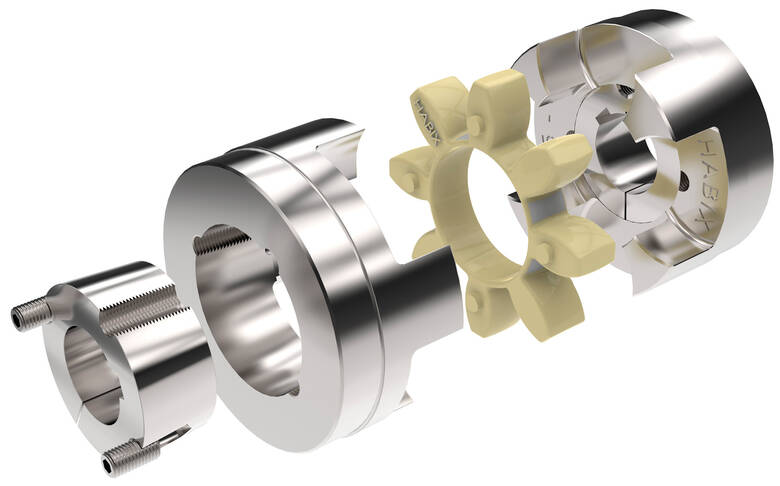

Bearing Pin Coupling Rubber-Cushioned Elastic Sleeves

The elastomer insert is equalizing element of coupling. It transmits torque without backlash or vibration. The elastomer insert defines the characteristics of the entire drive system. Backlash is eliminated by the press fit of the elastomer into the hubs. Through variation of the shore hardness of the elastomer insert, the coupling system can be optimized for the ideal torsional characteristics.

LT Pin Coupling Elastic Sleeve (Smooth Bushing)

| Part No. | Specification | Ref. Picture | ||

| d | D | L | ||

| LT-8 | 8 | 16 | 10 | |

| LT-10 | 10 | 19 | 15 | |

| LT-12 | 12 | 24 | 28 | |

| LT-14 | 14 | 26 | 28 | |

| LT-18 | 18 | 35 | 36 | |

| LT-24 | 24 | 45 | 44 | |

| LT-30 | 30 | 56 | 56 | |

| LT-38 | 38 | 71 | 72 | |

| LT-45 | 45 | 85 | 88 | |

ZT Pin Coupling Elastic Sleeve (Four Component Combined Elastic Sleeve)

| Part No. | d | D | L | Ref. Picture |

| ZT-8 | 8 | 16 | 10 | |

| ZT-10 | 10 | 19 | 15 | |

| ZT-14 | 14 | 28 | 27 | |

| ZT-18 | 18 | 36 | 35 | |

| ZT-24 | 24 | 45 | 44 | |

| ZT-30 | 30 | 56 | 55 | |

| ZT-38 | 38 | 71 | 72 | |

| ZT-45 | 45 | 85 | 88 |

FT Pin Coupling Elastic Sleeve Ring (Splited Elastic Ring Gasket)

| Part No. | d | D | L | Ref. Picture |

| FT-10 | 10 | 20 | 7 | |

| FT-12 | 12 | 24 | 7 | |

| FT-14 | 14 | 28 | 7 | |

| FT-14 | 14 | 29 | 7 | |

| FT-18 | 18 | 36 | 9 | |

| FT-18 | 18 | 38 | 9 | |

| FT-24 | 24 | 45 | 11 | |

| FT-24 | 24 | 48 | 11 | |

| FT-28 | 28 | 56 | 15 | |

| FT-30 | 30 | 56 | 15 | |

| FT-30 | 30 | 62 | 14 | |

| FT-38 | 38 | 71 | 18 | |

| FT-45 | 45 | 91 | 22 | |

| FT-45 | 45 | 85 | 23 |

Bearing Pin Coupling Rubber-Cushioned Elastic Sleeves

More Products:

Various types of couplings rubber elastomer models are as follows:

MT rubber coupling (MT1-MT13),

GR rubber coupling (GR10-GR180),

GS rubber coupling (GS7-GS90),

T Hexagon back wheel coupling (hexagonal elasticity pad T70 ~ 210).,

the fluid coupling (YOX),

L-type claw coupling hexagonal coupling (L35-L276),

H-type elastic block (H80-H350),

NM couplings elastomer (NM50 -NM214).

HRC Coupling elastomer (HRC60-HRC280).

Gear Sleeve Rubber Coupling Elastomer cushion (gear 4J-10J).

NL inner tooth gear coupling sleeve (NL1-NL10).

Oldham and non-standard high strength Spider rubber coupling.

Main Products:

custom couplings Plum pad, HRC couplings, Martin couplings, HRC couplings supply elastomer, HRC couplings elastic block, Gear Sleeve Rubber Coupling Elastomer, block rubber supply couplings, coupling rubber parts, coupling is rubber body, ZheJiang custom rubber gear coupling, screw compressor couplings, rubber supply gear couplings, Atlas coupling, screw compressor coupling, ZheJiang wholesale production of polyurethane gear, supply H-linking couplings, H-shaped elastic block coupling, H-type coupling rubber elastomer blocks

Please inquire us if you need Rubber Coupling Elastomer and other types couplings inserts.

| Different Types Of Hydraulic Seals | ||

| Application | Type | Material |

| Rod Seals | UN | TPU(PU,Polyurethane) |

| UNS | TPU(PU,Polyurethane) | |

| UHS | TPU(PU,Polyurethane) | |

| IDU | TPU(PU,Polyurethane) | |

| U+S | PU+NBR | |

| UPH | NBR & FKM | |

| Step Seal | NBR+PTFE | |

| VES | Rubber+Fabric | |

| IDI | PU | |

| ISI | PU | |

| Piston Seals | SPG | NBR+PTFE |

| SPGW | NBR+PTFE | |

| SPGO | NBR+PTFE | |

| KDAS | NBR+PU+POM | |

| ODI | PU | |

| OSI | PU | |

| ODU | PU | |

| Dust Wiper Seals | DH/DHS | PU |

| LBH | NBR & FKM | |

| J/JA | PU | |

| DKB | NBR & FKM +Metal | |

| DKBI | PU+Metal | |

| DSI | PU | |

| Wear Ring | WR | Phenolic Fabric |

| Xihu (West Lake) Dis. Tape | PTFE | |

| Xihu (West Lake) Dis. Tape | Phenolic Fabric | |

| Buffer Seal | HBY | PU+Nylon |

| Back-up Ring | O-Ring | NBR & FKM |

| X-Ring | NBR & FKM | |

| PTFE Washer | PTFE | |

Bearing Pin Coupling Rubber-Cushioned Elastic Sleeves

| Different Type Rotary Shaft Oil Seal | ||||

| Type | Material | Lip | Spring | Feature |

| TC | NBR & FKM | Double Lips | Single | Metal Coverd Rubber |

| TB | NBR | Double Lips | Single | Metal Case |

| TA | NBR | Double Lips | Single | Metal Case |

| SC | NBR & FKM | Single | Single | Double Metal Shell |

| SB | NBR | Single | Single | Metal Case |

| SA | NBR | Single | Single | Double Metal Shell |

| DC | NBR | Double Lips | Double | Double Springs |

| VC | NBR & FKM | Single | Without | Metal Coverd Rubber |

| VB | NBR | Single | Without | Metal Case |

| TCV | NBR | Double Lips | Single | High Pressure |

| TCN | NBR | Double Lips | Single | High Pressure |

| PTFE | PTFE | Single & Double Lips | Without | Stainless steel |

| HTCL | NBR & FKM | Double Lips | Single | Inside thread L |

| HTCR | NBR & FKM | Double Lips | Single | Inside thread R |

| …………………………………………………………………………………………… More types please contact us. Customization is welcome. |

||||

Related Products

Bearing Pin Coupling Rubber-Cushioned Elastic Sleeves

Oil seals serve to prevent the leakage not only of lubricants, but also water, chemicals, and gas from “gaps” in machinery. Oil seals also serve to prevent the intrusion of dust, soil and sand from the outside air.

Company Profile

HangZhou CHINAMFG Sealing Sci-Tech Co.Ltd. is a scientific and technological production enterprise integrating R&D, production and sales. Our production plant covers an area of about 2,000 square CHINAMFG and has 150 employees.

QMS (Quality Management System):

ISO9001, ISO/TS16949

Our Products:

O Ring, Oil Seal, Hydraulic & Pneumatic Seal, Custom CHINAMFG Parts

Production Standard:

ASTMD2000

Product Application Scope:

Engineering machinery, hydraulic pneumatic, petroleum and natural gas, automobile seals, valves and pipelines, electronic home appliances, food grade, electric power, chemical industry, coal mine, metallurgy, engineering shield machine and other industries, supporting domestic automobile and machinery manufacturers.

We had sell to:

More than 40 countries including the United States, Germany, Japan, Britain, Italy, Spain, Russia, Canada, Australia, Malaysia, Philippines, Indonesia, Mexico, Brazil, Peru, Chile, Argentina, Israel, Saudi Arabia, Lebanon, Ukraine, Pakistan, Thailand, Vietnam, etc.

Packaging & Shipping

Bearing Pin Coupling Rubber-Cushioned Elastic Sleeves

Ship by express, by air, by sea at buyer’s option.

rubber oil seal tc oil seal rubber seal manufacturer oil seal tc nbr oil seal tc oil seal fkm oil seal china manufacturer oil seal tc oil seal nbr tc oil seal fkm tc oil seal manufacturer

FAQ

Q 1. What’s the payment term?

A: We accept T/T 50% deposit and 50% balance against copy of B/L or L/C at sight, West Union,VISA,Paypal is also accepted. rubber oil seal tc oil seal rubber seal manufacturer oil seal tc nbr oil seal tc oil seal fkm oil seal china manufacturer oil seal tc oil seal nbr tc oil seal fkm tc oil seal manufacturer

Q 2. What is the normal lead time for product orders?

A: Generally it is 1-2 days if the goods are in stock. or it is 5-10 days if the goods are not in stock, it is according to quantity.tc oil seal tc oil seal nbr tc oil seal nbr rubber oil seal fkm oil seal fkm rubber oil seal manufacture china oil seal

tc oil seal tc oil seal nbr tc oil seal nbr rubber oil seal fkm oil seal fkm rubber oil seal manufacture china oil seal manufacture

Q 3. What is your standard packing?

A: All the goods will be packed by carton box and loaded with pallets. Special packing method can be accepted when needed.rubber oil seal tc oil seal rubber seal manufacturer oil seal tc nbr oil seal tc oil seal fkm oil seal china manufacturer oil seal tc oil seal nbr tc oil seal fkm tc oil seal manufacturer

Q 4. Could you please tell us the month capacity of your products ?

A: It depends on which model, we produce more than 2500 tons rubber materials per month.

tc oil seal tc oil seal nbr tc oil seal nbr rubber oil seal fkm oil seal fkm rubber oil seal manufacture china oil seal manufacture

Q 5. what kind of certificates you have ?

A1: We have been ISO9001:2008 and ISO14001:2004 certified by SGS since 2015.

A2: We have various rubber compounds approved by ROHS and REACH.

tc oil seal tc oil seal nbr tc oil seal nbr rubber oil seal fkm oil seal fkm rubber oil seal manufacture china oil seal manufacture

Q6: How to check the quality of the bulk order?

A1: We provide preproduction samples before mass production for all customers if needed.

A2: We accept third party inspection such as TUV, INTERTEK, BV, etc.

tc oil seal tc oil seal nbr tc oil seal nbr rubber oil seal fkm oil seal fkm rubber oil seal manufacture china oil seal manufacture

Q 7: Do you use any international standards for the rubber products?

A: Yes, we mainly use ASTM D2000 standard to define the quality of the rubber materials, tolerances as per ISO3302, ISO2768, etc.rubber oil seal tc oil seal rubber seal manufacturer oil seal tc nbr oil seal tc oil seal fkm oil seal china manufacturer oil seal tc oil seal nbr tc oil seal fkm tc oil seal manufacturer

Q8: What materials are available to produce from your side?

A: NBR, EPDM, SILICONE, FPM(FKM), NEOPRENE(CR), NR, IIR, SBR, ACM, AEM, Fluorosilicone(FVMQ), FFKM, Liquid Silicone, Sponge, etc. tc oi

l seal tc oil seal nbr tc oil seal nbr rubber oil seal fkm oil seal fkm rubber oil seal manufacture china oil seal manufacture

Q9: Do you provide maintenance on tooling?

A: We maintain all tooling and will replace as needed.tc oil seal tc oil seal nbr tc oil seal nbr rubber oil seal fkm oil seal fkm rubber oil seal manufacture china oil seal manufacture

Q10: How many empolyees you have?

A:We have 150 empolyees at time of December 2571. tc oil seal tc oil seal nbr tc oil seal nbr rubber oil seal fkm oil seal fkm rubber oil seal manufacture china oil seal manufacture

If you have any other question, please don’t hesitate to contact us:

Bearing Pin Coupling Rubber-Cushioned Elastic Sleeves /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Reducing Vibration and Shock in Machinery with Elastic Couplings

Elastic couplings play a crucial role in minimizing vibration and shock in machinery by offering flexibility and damping characteristics. Here’s how they contribute to this important function:

- Vibration Absorption: Elastic couplings are designed with flexible elements that can absorb and dampen vibrations generated by rotating machinery. These flexible elements act as shock absorbers, reducing the transmission of vibrations to other parts of the system.

- Isolation: The inherent flexibility of elastic couplings isolates vibrations and shocks from one side of the coupling to the other. This prevents vibrations from propagating throughout the connected components, helping to protect sensitive equipment and improve overall system performance.

- Resonance Damping: Elastic couplings can help dampen resonance frequencies that can occur in machinery during operation. By absorbing and dissipating energy, they reduce the risk of resonance-related issues that can lead to mechanical failure or decreased efficiency.

- Smooth Torque Transmission: Elastic couplings offer a smooth torque transmission that helps reduce sudden torque spikes and shocks during start-up or sudden load changes. This prevents abrupt mechanical stresses that can lead to vibration and shock propagation.

- Increased Equipment Lifespan: By minimizing the impact of vibrations and shocks, elastic couplings contribute to the longevity of connected machinery and components. Reduced vibration-related wear and tear can extend the service life of the entire system.

Overall, elastic couplings are effective tools for managing vibration and shock in machinery, enhancing operational reliability, reducing maintenance needs, and maintaining optimal performance.

Maintaining the Longevity of Elastic Couplings

Ensuring the longevity and optimal performance of elastic couplings requires proper maintenance and care. Here are some key considerations:

- Regular Inspection: Periodically inspect the coupling for signs of wear, damage, or misalignment. Look for cracks, tears, or other deformations in the elastic elements.

- Lubrication: Some elastic couplings require lubrication for smooth operation. Follow the manufacturer’s guidelines on lubrication intervals and recommended lubricants.

- Environmental Conditions: Consider the operating environment of the coupling. Extreme temperatures, chemicals, moisture, and other factors can affect the coupling’s lifespan. Choose materials and designs suitable for the specific conditions.

- Proper Alignment: Ensure that the connected components are properly aligned to minimize excessive stress on the coupling. Misalignment can accelerate wear and reduce performance.

- Load Capacity: Do not exceed the coupling’s recommended torque and load ratings. Overloading the coupling can lead to premature failure.

- Shock and Vibration: If the system experiences frequent shock or vibration, consider using dampening or vibration-absorbing components to reduce the stress on the coupling.

- Replacement: When signs of wear or damage become noticeable, promptly replace the coupling to avoid further issues. Delaying replacement can lead to more significant problems in the machinery system.

- Follow Manufacturer Guidelines: Always follow the manufacturer’s recommendations for installation, operation, and maintenance of the specific coupling model.

By adhering to these considerations and performing regular maintenance tasks, engineers can extend the lifespan of elastic couplings and ensure reliable and efficient operation in various machinery applications.

Benefits of Using Elastic Couplings in Industrial Machinery

Elastic couplings offer several advantages when used in industrial machinery:

- Misalignment Compensation: Elastic couplings can accommodate small angular, axial, and radial misalignments between connected shafts. This ability to compensate for misalignment helps prolong the life of machinery components and reduces the risk of premature wear.

- Vibration Damping: The elastic element in the coupling absorbs and dampens vibrations generated during operation. This feature improves the overall smoothness of machinery operation, reduces noise, and minimizes the transmission of vibrations to other parts of the system.

- Shock Absorption: Elastic couplings absorb sudden shocks or impacts that may occur during operation. By reducing the impact load on the connected components, the coupling helps prevent damage and extends the lifespan of the machinery.

- Reduced Maintenance: The flexibility and shock-absorbing properties of elastic couplings contribute to lower maintenance requirements. Machinery components experience less stress and wear, resulting in longer intervals between maintenance tasks.

- Protection of Equipment: Elastic couplings act as a protective barrier between connected machinery. They isolate vibrations and shocks, preventing these forces from propagating throughout the system and potentially causing damage.

- Improved Efficiency: By minimizing misalignment-related losses and reducing vibrations, elastic couplings contribute to improved machinery efficiency. This can lead to energy savings and better overall performance.

In summary, elastic couplings play a crucial role in enhancing the reliability, longevity, and efficiency of industrial machinery by addressing misalignment, dampening vibrations, absorbing shocks, and minimizing maintenance needs.

editor by CX 2024-05-06

China manufacturer POM Acetal Plastic Bulkhead Female Body Panel Mount Non-Valved Quick Disconnect Coupling coupling bearing

Product Description

Product Description

| Product Name | POM Acetal Plastic Bulkhead Female Body Panel Mount Non-Valved Quick Disconnect Coupling |

| Technology | Injection Molding |

| Usage | Standard flow quick-disconnect couplings require a body and an insert in the same flow size. Plug insert into body to connect fitting and easily disconnect the fitting by simply press the thumb latch. |

| Application | medical devices, laboratory, life science, biopharmaceutical, biochemical analysis, bioengineering, circulating water cooling pipe system, water treatment and disinfection, food&beverage, packaging machinery, industrial and hundreds of other applications; |

| Adapted Medium | Gas/Liquid |

| Material | POM Plastic |

| Seal Ring Material | Buna-N/FKM/EPDM/Silicone rubber, depend on your usage |

| Valve Spring | 316 Stainless Steel |

| Temperature Range | 32°F – 180°F (0°C – 82°C) |

| Pressure Range | Vacuum to 100 psi, 6.9bar |

| Valve Option | Valved(shut off) or Non-valved (straight through) |

| Shape Option | Panel Mount/In-line/Elbow/NPT Threaded; |

| Hose Barb Size | 1/16″ =1.6mm (01); 1/8″= 3.2mm (02); 3/16″= 4.8mm (03);

1/4″=6.4mm (04); 5/16″=8mm (05); 3/8″=9.6mm (06); |

| Threaded End | 1/8″-27NPT, 1/4″-18NPT Male Thread |

1/4″ Flow rate, 1/4″(6.4mm), 5/16″(8mm),3/8″(9.5mm) Hose Barb Coupling

Related Products You May Like

1/4″ Flow Rate All Plastic Series Couplings

1/8″ Flow Rate Medium Series Couplings

1/16″ Flow Rate Small Series Couplings

FAQ

Q1: Are you trading company or manufacturer?

A1: We are 15 years factory. Welcome to visit our factory.

Q2:What is your sample policy?

A2:

1. Only for terminal manufacturer;

2. Please kindly provide detail information of company for sample application process. Sample is available after confirmed and approved by management;

3.The international freight cost should be paid by the applicant;

Q3:What is your terms of payment?

A3: 100% payment before delivery; T/T 50% as deposit when mass customization, the balance before shipment.

Q4: How about your delivery time?

A4: Generally, it will take about 7-15 days after payment confirmed. The specific delivery time depends on the items and the ordered quantity .

Q5:What’s the shipping way?

A5: Usually by DHL, UPS, TNT, FedEx express or as your request.

Q6: Can you produce according to the samples?

A6: Yes, we can produce by your samples or technical drawings. We accept ODM & OEM.

Company Profile

|

Shipping Cost:

Estimated freight per unit. |

To be negotiated |

|---|

| Standard: | RoHS |

|---|---|

| Material: | POM |

| Connection: | Hose Barb |

| Customization: |

Available

| Customized Request |

|---|

Programming With Couplings

A coupling is a mechanical device that connects two shafts together and transmits power. Its purpose is to join rotating equipment and allows some degree of end-movement or misalignment. There are many different types of couplings. It’s important to choose the right one for your application.

Mechanical connection between two shafts

There are many ways to achieve mechanical connection between two shafts, including the use of a coupling. One common type is the beam coupling, which is also known as a helical coupling. It is used for transmission of torque between two shafts. This type of connection accommodates axial, parallel and angular misalignments.

The hubs and shafts of a worm gear are connected together by a coupling. This mechanical connection allows one shaft to turn another without causing a mechanical failure. This type of coupling is made from sliding or rubbing parts to transfer torque. However, the coupling is not designed to withstand jerks, so it isn’t suitable for high-speed applications.

The use of a coupling is common in machinery and equipment. It helps transmit power from one drive shaft to the other, while adding mechanical flexibility. It is also useful for reducing the impact and vibration caused by misalignment. It also protects the drive shaft components from wear and tear.

A double-hook coupling can be used to provide a uniform angular velocity at the driven shaft. Another example is a double-jointed coupling. A double-jointed coupling can be used to connect shafts that are not directly intersecting. The double-jointed yoke can be used for the same purpose.

A shaft coupling is a device that maintains a strong mechanical connection between two shafts. It transfers motion from one shaft to another, at all loads and misalignments. Unlike a conventional linkage, a shaft coupling isn’t designed to allow relative motion between the two shafts. Couplings often serve several purposes in a machine, but their primary use is torque and power transmission.

Functions that control the flow of another function

One of the simplest programming constructs is a function that controls the flow of another function. A function can take an argument and return a different value, but it must be ready to return before it can pass that value to another function. To do this, you can use the goto statement and the if statement. Another way to control flow is to use a conditional statement.

Criteria for selecting a coupling

There are several important factors to consider when choosing the right coupling. One of the most important factors is coupling stiffness, which depends on the material used and the shape. The stiffness of a coupling determines its ability to resist elastic deformation. A stiff coupling is desirable for certain types of applications, but it’s undesirable for others. Stiffness can reduce the performance of a system if there’s too much inertia. To avoid this, ensure that the coupling you choose is within the recommended limits.

The size of a coupling is also important. Different coupling types can accommodate different shaft sizes and shapes. Some couplings have special features, such as braking and shear pin protection. When choosing a coupling, you should also consider the type of driven equipment. If you need to connect a high-torque motor, for example, you’ll want to choose a gear coupling. Likewise, a high-speed machine may require a disc coupling.

Another factor to consider when selecting a coupling is the torque rating. Despite its importance, it’s often underestimated. The torque rating is defined as the torque of the coupling divided by its OD. In some cases, torque may fluctuate during a cycle, requiring a coupling with a higher torque rating.

Torsionally flexible couplings are also important to consider. Their design should be able to withstand the torque required during operation, as well as the required speed. The coupling should also have a high degree of torsional stiffness, as well as damping. Furthermore, a damping coupling can reduce the energy wasted through vibration.

The sizing of a coupling is also determined by the torque. Many engineers use torque to select the correct coupling size, but they also take into consideration torsional flexibility and torsional stiffness. For example, a shaft may be able to handle large torque without damaging the coupling, while a disk may be unable to handle large amounts of torque.

Besides torque, another important consideration in coupling selection is the cost. While a coupling may be cheaper, it may be less reliable or easier to maintain. Couplings that are difficult to service may not last as long. They may also require frequent maintenance. If that’s the case, consider purchasing a coupling with a low service factor.

There are many different types of couplings. Some require additional lubrication throughout their lifetime, while others are 100% lubrication-free. An example of a 100% lubrication-free coupling is the RBI flexible coupling from CZPT. This type of coupling can significantly reduce your total cost of ownership.

In addition to the above-mentioned benefits, elastomeric couplings are low-cost and need little maintenance. While they are often cheaper than metallic couplings, they also have excellent shock absorption and vibration dampening properties. However, they are susceptible to high temperatures. Also, they are difficult to balance as an assembly, and have limited overload torque capacity.

editor by CX 2023-07-11

China Hot selling Stainless Steel Quick Connect/Quick Disconnect Air Hose Fittings Coupling coupling bearing

Product Description

Air Hose Coupling

| Type 1 | European Type |

| Type 2 | American Type |

Universal Air Hose Coupling Male Thread End

1.The coupling are made of carbon steel

2. US type and European type are available

3 The locking jaws are heavy with large bulk surface which cannot bend or break loose

4.Coupling are interchangeable between various sizes

| Connection: | Male or Female |

|---|---|

| Flexible or Rigid: | Rigid |

| Material: | Cast Iron or Malleable Steel |

| Standard: | Standard |

| Product Name: | Air Hose Coupling |

| Type 1: | European Type |

| Customization: |

Available

| Customized Request |

|---|

Types of Couplings

A coupling is a device that connects two shafts and transmits power from one to the other. Its main purpose is to join two pieces of rotating equipment. It also allows for some degree of misalignment or end movement. Here are a few examples of coupling types: Beam coupling, Flexible coupling, Magnetic coupling, and Shaft coupling.

Beam coupling

Beam couplings are used to couple motors and other devices. They are available in several types, including flexible, slit, and rigid beam couplings. Each has unique properties and characteristics. These couplings are best for applications requiring a high level of precision and long life. They are also a practical solution for the connection of stepping and servo motors with screw rods.

Beam couplings are usually made of stainless steel or aluminum alloy, and feature spiral and parallel cut designs. Multiple cuts allow the coupling to accommodate multiple beams and improve angular and parallel misalignment tolerances. Additionally, beam couplings are comparatively cheaper than other types of rotary joints, and they require minimal maintenance.

The materials of a beam coupling should be considered early in the specification process. They are typically made of aluminum or stainless steel, but they can also be manufactured from Delrin, titanium, and other engineering grade materials. Beam couplings are often available in multiple sizes to fit specific shaft diameters.

Beam couplings are a key component of motion control systems. They provide excellent characteristics when used properly, and they are a popular choice for many applications. A thorough understanding of each type of coupling will help to prevent coupling failure and enhance system performance. Therefore, it is important to choose the right coupling for your application.

Various types of beam couplings have unique advantages and disadvantages. The FCR/FSR design has two sets of three beams. It is available in both metric and inch shaft sizes. The FCR/FSR couplings are ideal for light-duty power transmission applications. A metric shaft is more suitable for these applications, while an inch shaft is preferred for heavier duty applications.

Two types of beam couplings are available from Ruland. The Ruland Flexible beam coupling has a multi-helical cut design that offers a greater flexibility than commodity beam couplings. This design allows for higher torque capabilities while minimizing wind-up. In addition, it is also more durable than its commodity counterparts.

Flexible coupling

A flexible coupling is a versatile mechanical connection that allows for the easy coupling of two moving parts. The design of these couplings allows for a variety of stiffness levels and can address a variety of problems, such as torsional vibrations or critical speed. However, there are a number of tradeoffs associated with flexible couplings.

One of the biggest issues is the installation of the coupling, which requires stretching. This problem can be exacerbated by cold temperatures. In such a case, it is vital to install the coupling properly. Using a gear clamp is one of the most important steps in a successful installation. A gear clamp will keep the coupling in place and prevent it from leaking.

Another common type of flexible coupling is the gear coupling. These couplings are composed of two hubs with crowned external gear teeth that mesh with two internally splined flanged sleeves. The massive size of the teeth makes them resemble gears. Gear couplings offer good torque characteristics but require periodic lubrication. These couplings can also be expensive and have a limited number of applications.

Another type of flexible coupling is the SDP/SI helical coupling. These couplings can accommodate axial motion, angular misalignment, and parallel offset. This design incorporates a spiral pattern that makes them flexible. These couplings are available in stainless steel and aluminum.

A flexible coupling has a wide range of applications. Generally, it is used to connect two rotating pieces of equipment. Depending on its design, it can be used to join two pieces of machinery that move in different directions. This type of coupling is a type of elastomeric coupling, which has elastic properties.

There are many types of flexible couplings available for different types of applications. The purpose of a flexible coupling is to transmit rotational power from one shaft to another. It is also useful for transmitting torque. However, it is important to note that not all flexible couplings are created equally. Make sure to use a reputable brand for your coupling needs. It will ensure a reliable connection.

The simplest and most commonly used type of flexible coupling is the grid coupling. This type of coupling uses two hubs with slotted surfaces. The steel grid is allowed to slide along these slots, which gives it the ability to flex. The only limitation of this type of coupling is that it can only tolerate a 1/3 degree misalignment. It can transmit torques up to 3,656 Nm.

Magnetic coupling

Magnetic coupling is a technique used to transfer torque from one shaft to another using a magnetic field. It is the most common type of coupling used in machinery. It is highly effective when transferring torque from a rotating motor to a rotating shaft. Magnetic couplings can handle high torques and high speeds.

Magnetic coupling is described by the energy difference between a high-spin state and a broken symmetry state, with the former being the energy of a true singlet state. In single-determinant theories, this energy difference is called the Kij. Usually, the broken-symmetry state is a state with two interacting local high-spin centers.

The magnetic coupling device is regarded as a qualitative leap in the reaction still industry. It has solved a number of problems that had plagued the industry, including flammability, explosiveness, and leakage. Magnetic couplings are a great solution for many applications. The chemical and pharmaceutical industries use them for various processes, including reaction stills.

Magnetic couplings are a good choice for harsh environments and for tight spaces. Their enclosed design keeps them fluid and dust-proof. They are also corrosion-resistant. In addition, magnetic couplings are more affordable than mechanical couplings, especially in areas where access is restricted. They are also popular for testing and temporary installations.

Another use for magnetic coupling is in touch screens. While touch screens use capacitive and resistive elements, magnetic coupling has found a cool new application in wireless charging. While the finger tracking on touch screens may seem like a boley job, the process is very sensitive. The devices that use wireless charging need to have very large coils that are locked into resonant magnetic coupling.

Magnetic couplings also help reduce hydraulic horsepower. They cushion starts and reduce alignment problems. They can also improve flow in oversized pumps. A magnetic coupling with an 8 percent air gap can reduce hydraulic HP by approximately 27 percent. In addition, they can be used in aggressive environments. They also help reduce repair costs.

Magnetic couplings are a great choice for pumps and propeller systems because they have the added advantage of being watertight and preventing shaft failure. These systems also have the benefit of not requiring rotating seals.

Shaft coupling

A shaft coupling joins two shafts and transmits rotational motion. Generally, shaft couplings allow for some degree of misalignment, but there are also torque limiters. Selecting the right coupling can save you time and money and prevent equipment downtime. Here are the main features to consider when purchasing a coupling for your application.

Shaft couplings should be easy to install and disassemble, transmit full power to the mated shaft, and reduce shock loads. A shaft coupling that does not have projecting parts should be used for machines that move or rotate at high speeds. Some types of shaft couplings are flexible while others are rigid.

Shaft couplings can be used in a variety of applications, including piping systems. They can be used to connect shafts that are misaligned and help maintain alignment. They can also be used for vibration dampening. Shaft couplings also allow shafts to be disconnected when necessary.

Shaft couplings can accommodate a certain amount of backlash, but this backlash must be well within the tolerance set by the system. Extremely high backlash can break the coupling and cause excessive wear and stress. In addition, excessive backlash can lead to erratic alignment readings. To avoid these issues, operators must reduce backlash to less than 2deg.

Shaft couplings are often referred to by different names. Some are referred to as “sliced” couplings while others are known as “slit” couplings. Both types offer high torque and torsional stiffness. These couplings are typically made from metals with various alloys, such as acetal, stainless steel, or titanium.

CZPT Pulley produces shaft couplings for a variety of applications. These products are used in high-power transmission systems. They have several advantages over friction couplings. In addition to minimizing wear, they don’t require lubrication. They are also capable of transmitting high torque and high speeds.

Another type of shaft coupling is the universal coupling. It is used to transmit power to multiple machines with different spindles. Its keyed receiving side and flanges allow it to transmit power from one machine to another.

editor by CX 2023-04-18

China supplier Stainless Steel 316L/304 Threaded Pipe Fittings, Coupling 3 in. Stainless Steel for Rigid Conduit, Stainless Steel Hydraulic Fittings coupling bearing

Product Description

Product Description

Stainless steel pipe fittings, double-head threaded joint, thread alignment.Stainless steel 316 food-grade connector, non-standard connector customized.Stainless steel single-head internal thread, 1/2 internal thread pipe fittings, pipe fittings.Stainless steel single-head internal thread, 2-inch internal thread pipe fittings, 304 pipe fitting.BSPT/ NPT Thread, Pipe Fittings Threaded Merchant Couplings.

Detailed Photos

Company Profile

Our company was founded in 2017. It is located in HangZhou City, 7 kilometers away from the airport, 30 minutes from the high-speed railway station, and 300 kilometers from the nearest port, HangZhou Port.

We are a manufacturer specializing in the production of stainless steel hardware. The product features stainless steel products such as nuts, connectors, bolts, valves and sanitary fittings, explosion-proof connectors and pneumatic connectors. The products are applicable to automobile and motorcycle, plumbing, valves, water pumps, doors and windows, machinery, pneumatic tools, explosion-proof electrical appliances and other industries.

We have our own inventory warehouse, and can also make customized production according to customers’ drawings or samples,Our processes include cold heading, hot heading and CNC finishing.

We have always focused on “quality makes more customers, price makes more market, and service makes more future”,Finally, we sincerely look CZPT to your visit and detailed negotiation and cooperation.

FAQ

| Q: | How can you guarantee the delivery time? |

| A: | 1. To avoid the delay, we have built a complete and professional procedure system from production to the deliver and have rich experience. 2. We can regulate the penalty clause in the contract for the late delay. |

| Q: | What’s your best price? |

| A: | Based on the quality of our products and the quantity of your estimated. We would quote the great best matching price all the time. |

| Q: | What’s your MOQ? Can I print our LOGO? |

| A: | Of course, the MOQ of each product is 10000 pcs |

| Q: | Can I print our own logo on the product? |

| A: | Yes, Please send your logo to us. |

| Q: | Can you provide OEM/ODM service? |

| A: | Yes, we can. Please tell us the details of your requirements |

| Q: | How can you prove your business credit and make my business safe? |

| A: | You could use Made in China Trade Assurance for your payment. If the delivery is not ok. The Trade Assurance would be safe for your money |

| Q: | Why choose us to cooperate? |

| A: | 1. We have first-class production line and strict quality management system.

2. We have professional procedure system and big production capacity to guarantee fast deliver and on time shipment. 3. We can provide the most competitive price to meet your budget. 4. We also design and innovate the new products based on our rich experience . 5. We have professional team to provide comprehensive one-stop service for you.

|

| After-sales Service: | Yes |

|---|---|

| Warranty: | 2 Years |

| Material: | Stainless Steel |

| Connection: | Male |

| OEM: | Available |

| Sample: | Available |

| Samples: |

US$ 5/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Types of Coupling

A coupling is a device used to join two shafts together and transmit power. Its primary function is to join rotating equipment and allows for some end movement and misalignment. This article discusses different types of coupling, including Magnetic coupling and Shaft coupling. This article also includes information on Overload safety mechanical coupling.

Flexible beam coupling

Flexible beam couplings are universal joints that can deal with shafts that are offset or at an angle. They consist of a tube with couplings at both ends and a thin, flexible helix in the middle. This makes them suitable for use in a variety of applications, from motion control in robotics to attaching encoders to shafts.

These couplings are made of one-piece materials and are often made of stainless steel or aluminium alloy. However, they can also be made of acetal or titanium. While titanium and acetal are less common materials, they are still suitable for high-torque applications. For more information about beam couplings, contact CZPT Components.

Flexible beam couplings come in a variety of types and sizes. W series couplings are good for general purpose applications and are relatively economical. Stainless steel versions have increased torque capacity and torsional stiffness. Flexible beam couplings made of aluminum are ideal for servo and reverse motion. They are also available with metric dimensions.

Flexible beam couplings are made of aluminum alloy or stainless steel. Their patented slot pattern provides low bearing load and high torsional rigidity. They have a long operational life. They also require zero maintenance and can handle angular offset. Their advantages outweigh the disadvantages of traditional beam couplings.

Magnetic coupling

Magnetic coupling transfers torque from one shaft to another using a magnetic field. These couplings can be used on various types of machinery. These types of transmissions are very useful in many situations, especially when you need to move large amounts of weight. The magnetic field is also very effective at reducing friction between the two shafts, which can be extremely helpful if you’re moving heavy items or machinery.

Different magnetic couplings can transmit forces either linearly or rotated. Different magnetic couplings have different topologies and can be made to transmit force in various geometric configurations. Some of these types of couplings are based on different types of materials. For example, a ceramic magnetic material can be used for applications requiring high temperature resistance.

Hybrid couplings are also available. They have a hybrid design, which allows them to operate in either an asynchronous or synchronous mode. Hysterloy is an alloy that is easily magnetized and is used in synchronous couplings. A synchronous magnetic coupling produces a coupled magnetic circuit.

Magnetic coupling is a key factor in many physical processes. In a crystal, molecules exhibit different magnetic properties, depending on their atomic configuration. Consequently, different configurations produce different amounts of magnetic coupling. The type of magnetic coupling a molecule exhibits depends on the exchange parameter Kij. This exchange parameter is calculated by using quantum chemical methods.

Magnetic couplings are most commonly used in fluid transfer pump applications, where the drive shaft is hermetically separated from the fluid. Magnetic couplings also help prevent the transmission of vibration and axial or radial loads through the drive shaft. Moreover, they don’t require external power sources, since they use permanent magnets.

Shaft coupling

A shaft coupling is a mechanical device that connects two shafts. The coupling is designed to transmit full power from one shaft to the other, while keeping the shafts in perfect alignment. It should also reduce transmission of shock loads. Ideally, the coupling should be easy to connect and maintain alignment. It should also be free of projecting parts.

The shaft couplings that are used in machines are typically made of two types: universal coupling and CZPT coupling. CZPT couplings are designed to correct for lateral misalignment and are composed of two flanges with tongues and slots. They are usually fitted with pins. The T1 tongue is fitted into flange A, while the T2 tongue fits into flange B.

Another type of shaft coupling is known as a “sliced” coupling. This type of coupling compensates for inevitable shaft misalignments and provides high torque. Machined slits in the coupling’s outer shell help it achieve high torsional stiffness and excellent flexibility. The design allows for varying engagement angles, making it ideal for many different applications.

A shaft coupling is an important component of any machine. Proper alignment of the two shafts is vital to avoid machine breakdowns. If the shafts are misaligned, extra force can be placed on other parts of the machine, causing vibration, noise, and damage to the components. A good coupling should be easy to connect and should ensure precise alignment of the shaft. Ideally, it should also have no projecting parts.

Shaft couplings are designed to tolerate a certain amount of backlash, but it must be within a system’s threshold. Any angular movement of the shaft beyond this angle is considered excessive backlash. Excessive backlash results in excessive wear, stress, and breakage, and may also cause inaccurate alignment readings. It is therefore imperative to reduce backlash before the shaft alignment process.

Overload safety mechanical coupling

Overload safety mechanical couplings are devices that automatically disengage when the torque applied to them exceeds a specified limit. They are an efficient way to protect machinery and reduce the downtime associated with repairing damaged machinery. The advantage of overload couplings is their fast reaction time and ease of installation.

Overload safety mechanical couplings can be used in a wide range of applications. Their automatic coupling mechanisms can be used on any face or edge. In addition, they can be genderless, incorporating both male and female coupling features into a single mechanism. This means that they are both safe and gender-neutral.

Overload safety couplings protect rotating power transmission components from overloads. Overload protection devices are installed on electric motors to cut off power if the current exceeds a certain limit. Likewise, fluid couplings in conveyors are equipped with melting plug elements that allow the fluid to escape when the system becomes too hot. Mechanical force transmission devices, such as shear bolts, are designed with overload protection in mind.

A common design of an overload safety mechanical coupling consists of two or more arms and hubs separated by a plastic spider. Each coupling body has a set torque threshold. Exceeding this threshold may damage the spider or damage the jaws. In addition, the spider tends to dampen vibration and absorb axial extension. This coupling style is nearly backlash free, electrically isolating, and can tolerate very little parallel misalignment.

A mechanical coupling may also be a universal joint or jaw-clutch coupling. Its basic function is to connect the driver and driven shafts, and limits torque transfer. These devices are typically used in heavy-duty industries, such as steel plants and rolling mills. They also work well with industrial conveyor systems.

CZPT Pulley

The CZPT Pulley coupling family offers a comprehensive range of couplings for motors of all types. Not only does this range include standard motor couplings, but also servo couplings, which require ultra-precise control. CZPT Pulley couplings are also suitable for engine applications where high shocks and vibrations are encountered.

CZPT Pulley couplings have a “sliced” body structure, which allows for excellent torsional stiffness and strength. They are corrosion-resistant and can withstand high rotational speeds. The couplings’ design also ensures accurate shaft rotation while limiting shaft misalignment.

CZPT Pulley has introduced the CPU Pin Type couplings, which are effective at damping vibration and maintain zero backlash. They are also made from aluminum and are capable of absorbing heat. They come with recessed tightening screws. They can handle speeds up to 4,000 RPM, and are RoHS-compliant.

editor by CX 2023-04-18

China UL Listed Steel Pipe Couplings coupling bearing

Product Description

UL List, good good quality

Fireplace battling, fireplace combating products, hearth extinguisher, smoke detector, fire hose, fireplace alarm, hearth blanket, hearth hose reel, fire cupboard.

|

/ Piece | |

1,000 Pieces (Min. Order) |

###

| Connection: | Grooved |

|---|---|

| Shape: | Equal |

| Head Code: | Round |

| Angle: | 180 Degree |

| Wall Thickness: | Sch10 |

| Material: | Carbon Steel |

###

| Customization: |

|---|

###

|

/ Piece | |

1,000 Pieces (Min. Order) |

###

| Connection: | Grooved |

|---|---|

| Shape: | Equal |

| Head Code: | Round |

| Angle: | 180 Degree |

| Wall Thickness: | Sch10 |

| Material: | Carbon Steel |

###

| Customization: |

|---|

###

Programming With Couplings

A coupling is a mechanical device that connects two shafts together and transmits power. Its purpose is to join rotating equipment and allows some degree of end-movement or misalignment. There are many different types of couplings. It’s important to choose the right one for your application.

Mechanical connection between two shafts

There are many ways to achieve mechanical connection between two shafts, including the use of a coupling. One common type is the beam coupling, which is also known as a helical coupling. It is used for transmission of torque between two shafts. This type of connection accommodates axial, parallel and angular misalignments.

The hubs and shafts of a worm gear are connected together by a coupling. This mechanical connection allows one shaft to turn another without causing a mechanical failure. This type of coupling is made from sliding or rubbing parts to transfer torque. However, the coupling is not designed to withstand jerks, so it isn’t suitable for high-speed applications.

The use of a coupling is common in machinery and equipment. It helps transmit power from one drive shaft to the other, while adding mechanical flexibility. It is also useful for reducing the impact and vibration caused by misalignment. It also protects the drive shaft components from wear and tear.

A double-hook coupling can be used to provide a uniform angular velocity at the driven shaft. Another example is a double-jointed coupling. A double-jointed coupling can be used to connect shafts that are not directly intersecting. The double-jointed yoke can be used for the same purpose.

A shaft coupling is a device that maintains a strong mechanical connection between two shafts. It transfers motion from one shaft to another, at all loads and misalignments. Unlike a conventional linkage, a shaft coupling isn’t designed to allow relative motion between the two shafts. Couplings often serve several purposes in a machine, but their primary use is torque and power transmission.

Functions that control the flow of another function

One of the simplest programming constructs is a function that controls the flow of another function. A function can take an argument and return a different value, but it must be ready to return before it can pass that value to another function. To do this, you can use the goto statement and the if statement. Another way to control flow is to use a conditional statement.

Criteria for selecting a coupling

There are several important factors to consider when choosing the right coupling. One of the most important factors is coupling stiffness, which depends on the material used and the shape. The stiffness of a coupling determines its ability to resist elastic deformation. A stiff coupling is desirable for certain types of applications, but it’s undesirable for others. Stiffness can reduce the performance of a system if there’s too much inertia. To avoid this, ensure that the coupling you choose is within the recommended limits.

The size of a coupling is also important. Different coupling types can accommodate different shaft sizes and shapes. Some couplings have special features, such as braking and shear pin protection. When choosing a coupling, you should also consider the type of driven equipment. If you need to connect a high-torque motor, for example, you’ll want to choose a gear coupling. Likewise, a high-speed machine may require a disc coupling.

Another factor to consider when selecting a coupling is the torque rating. Despite its importance, it’s often underestimated. The torque rating is defined as the torque of the coupling divided by its OD. In some cases, torque may fluctuate during a cycle, requiring a coupling with a higher torque rating.

Torsionally flexible couplings are also important to consider. Their design should be able to withstand the torque required during operation, as well as the required speed. The coupling should also have a high degree of torsional stiffness, as well as damping. Furthermore, a damping coupling can reduce the energy wasted through vibration.

The sizing of a coupling is also determined by the torque. Many engineers use torque to select the correct coupling size, but they also take into consideration torsional flexibility and torsional stiffness. For example, a shaft may be able to handle large torque without damaging the coupling, while a disk may be unable to handle large amounts of torque.

Besides torque, another important consideration in coupling selection is the cost. While a coupling may be cheaper, it may be less reliable or easier to maintain. Couplings that are difficult to service may not last as long. They may also require frequent maintenance. If that’s the case, consider purchasing a coupling with a low service factor.

There are many different types of couplings. Some require additional lubrication throughout their lifetime, while others are 100% lubrication-free. An example of a 100% lubrication-free coupling is the RBI flexible coupling from CZPT. This type of coupling can significantly reduce your total cost of ownership.

In addition to the above-mentioned benefits, elastomeric couplings are low-cost and need little maintenance. While they are often cheaper than metallic couplings, they also have excellent shock absorption and vibration dampening properties. However, they are susceptible to high temperatures. Also, they are difficult to balance as an assembly, and have limited overload torque capacity.

editor by CX 2023-03-31

China API 5CT N80q Standard Petroleum Oil Casing Steel Seamless Pipe and Tubing Coupling coupling bearing

Solution Description

THE Principal Merchandise OF THE Enterprise.

Tubing and casing couplings for oilfield,specs from 2-3/8″-twenty”,metal grade from J55-Q125.

Primary Raw Supplies SUPPLIERS.

ZheJiang Seamless Metal Pipe PlantZheJiang Changbao Precision Steel Tube Co.,LtdZheJiang TiHangZhou Oil Pipe Co.,LtdHuaian Zhenda Metal Tube Production Co.,LtdZheJiang HangZhou Steel Union Co.,Ltd.

|

Dimensions and Technical specs For Tubing and Casing Couplings |

||||

| Descriptions and Measurement | Type of Thread | O.D* L | Bodyweight | |

| (mm) | (kg) | |||

| Tubing Coupling | two-3/8″ | NUE | 73.02*107.95 | 1.28 |

| 2-3/8″ | EUE | seventy seven.80*123.82 | 1.55 | |

| 2-7/8″ | NUE | 88.90*one hundred thirty.18 | two.34 | |

| two-7/8″ | EUE | 93.17*133.35 | 2.four | |

| three-1/2″ | NUE | 107.95*142.88 | 3.seventy one | |

| three-1/2″ | EUE | 114.30*146.05 | four.one | |

| 4″ | NUE | 120.65*146.05 | 4.35 | |

| 4″ | EUE | 127.00*152.40 | 4.eighty two | |

| four-1/2″ | NUE | 132.08*a hundred and fifty five.58 | four.89 | |

| 4-1/2″ | EUE | 141.30*158.75 | 6.05 | |

| Casing Coupling | four-1/2″ | STC | 127.00*158.seventy five | 5.23 |

| 4-1/2″ | LTC | 127.00*177.80 | 4.fifteen | |

| four-1/2″ | BTC | 133.35*225.42 | 6.89 | |

| 5″ | STC | 147.32*165.10 | four.sixty six | |

| five” | LTC | 147.32*196.85 | 5.seventy five | |

| five” | BTC | 147.32*231.78 | five.eighty five | |

| 5-1/2″ | STC | 153.67*171.forty five | five.23 | |

| five-1/2″ | LTC | 160.02*203.20 | eight.92 | |

| five-1/2″ | BTC | 153.sixty seven*234.ninety five | six.36 | |

| 6-5/8″ | STC | 187.seventy one*184.fifteen | nine.12 | |

| six-5/8″ | LTC | 187.71*222.twenty five | eleven.34 | |

| six-5/8″ | BTC | 187.seventy one*244.forty eight | 11.01 | |

| seven” | STC | 194.46*184.15 | eight.39 | |

| 7″ | LTC | 194.46*228.60 | 10.eighty three | |

| seven” | BTC | 194.46*254.00 | ten.fifty four | |

| seven-5/8″ | STC | 215.ninety*190.50 | twelve.3 | |

| seven-5/8″ | LTC | 215.90*234.95 | fifteen.63 | |

| 7-5/8″ | BTC | 215.90*263.fifty two | 15.eighty two | |

| 8-5/8″ | STC | 244.48*196.85 | sixteen.23 | |

| eight-5/8″ | LTC | 244.48*254.00 | 21.67 | |

| 8-5/8″ | BTC | 244.forty eight*269.88 | twenty.86 | |

| 9-5/8″ | STC | 269.88*196.eighty five | eighteen.03 | |

| 9-5/8″ | LTC | 269.88*266.70 | twenty five.forty five | |

| 9-5/8″ | BTC | 269.88*269.88 | 23.16 | |

| ten-3/4″ | STC | 298.forty five*203.20 | twenty.seventy eight | |

| 10-3/4″ | BTC | 298.45*269.88 | twenty five.74 | |

| 11-3/4″ | STC | 323.85*203.twenty | 22.sixty four | |

| eleven-3/4″ | BTC | 323.85*269.88 | 28.03 | |

| 13-3/8″ | STC | 365.twelve*203.twenty | 25.sixty six | |

| 13-3/8″ | BTC | 365.12*269.88 | 31.77 | |

| 16″ | STC/LTC | 431.80*228.sixty | 34.ninety one | |

| 16″ | BTC | 431.80*269.88 | forty.28 | |

| eighteen-5/8″ | STC/LTC | 508.00*228.sixty | 54.01 | |

| 18-5/8″ | BTC | 508.00*269.88 | 62.68 | |

| 20″ | STC/LTC | 533.forty*228.60 | 43.forty two | |

| twenty” | BTC | 533.forty*269.88 | fifty.ten | |

|

/ Piece | |

2,379 Pieces (Min. Order) |

###

| After-sales Service: | One Year |

|---|---|

| Warranty: | One Year |

| Manufacturing Process: | CNC Milling |

| Surface Treatment: | Spray-Paint |

| Operation Pressure: | Atmospheric Pressure |

| Material: | Alloy |

###

| Samples: |

US$ 18/Piece

1 Piece(Min.Order) |

|---|

###

|

Size and Specifications For Tubing and Casing Couplings |

||||

| Descriptions and Size | Type of Thread | O.D* L | Weight | |

| (mm) | (kg) | |||

| Tubing Coupling | 2-3/8" | NUE | 73.02*107.95 | 1.28 |

| 2-3/8" | EUE | 77.80*123.82 | 1.55 | |

| 2-7/8" | NUE | 88.90*130.18 | 2.34 | |

| 2-7/8" | EUE | 93.17*133.35 | 2.4 | |

| 3-1/2" | NUE | 107.95*142.88 | 3.71 | |

| 3-1/2" | EUE | 114.30*146.05 | 4.1 | |

| 4" | NUE | 120.65*146.05 | 4.35 | |

| 4" | EUE | 127.00*152.40 | 4.82 | |

| 4-1/2" | NUE | 132.08*155.58 | 4.89 | |

| 4-1/2" | EUE | 141.30*158.75 | 6.05 | |

| Casing Coupling | 4-1/2" | STC | 127.00*158.75 | 5.23 |

| 4-1/2" | LTC | 127.00*177.80 | 4.15 | |

| 4-1/2" | BTC | 133.35*225.42 | 6.89 | |

| 5" | STC | 147.32*165.10 | 4.66 | |

| 5" | LTC | 147.32*196.85 | 5.75 | |

| 5" | BTC | 147.32*231.78 | 5.85 | |

| 5-1/2" | STC | 153.67*171.45 | 5.23 | |

| 5-1/2" | LTC | 160.02*203.20 | 8.92 | |

| 5-1/2" | BTC | 153.67*234.95 | 6.36 | |

| 6-5/8" | STC | 187.71*184.15 | 9.12 | |

| 6-5/8" | LTC | 187.71*222.25 | 11.34 | |

| 6-5/8" | BTC | 187.71*244.48 | 11.01 | |

| 7" | STC | 194.46*184.15 | 8.39 | |

| 7" | LTC | 194.46*228.60 | 10.83 | |

| 7" | BTC | 194.46*254.00 | 10.54 | |

| 7-5/8" | STC | 215.90*190.50 | 12.3 | |

| 7-5/8" | LTC | 215.90*234.95 | 15.63 | |

| 7-5/8" | BTC | 215.90*263.52 | 15.82 | |

| 8-5/8" | STC | 244.48*196.85 | 16.23 | |

| 8-5/8" | LTC | 244.48*254.00 | 21.67 | |

| 8-5/8" | BTC | 244.48*269.88 | 20.86 | |

| 9-5/8" | STC | 269.88*196.85 | 18.03 | |

| 9-5/8" | LTC | 269.88*266.70 | 25.45 | |

| 9-5/8" | BTC | 269.88*269.88 | 23.16 | |

| 10-3/4" | STC | 298.45*203.20 | 20.78 | |

| 10-3/4" | BTC | 298.45*269.88 | 25.74 | |

| 11-3/4" | STC | 323.85*203.20 | 22.64 | |

| 11-3/4" | BTC | 323.85*269.88 | 28.03 | |

| 13-3/8" | STC | 365.12*203.20 | 25.66 | |

| 13-3/8" | BTC | 365.12*269.88 | 31.77 | |

| 16" | STC/LTC | 431.80*228.60 | 34.91 | |

| 16" | BTC | 431.80*269.88 | 40.28 | |

| 18-5/8" | STC/LTC | 508.00*228.60 | 54.01 | |

| 18-5/8" | BTC | 508.00*269.88 | 62.68 | |

| 20" | STC/LTC | 533.40*228.60 | 43.42 | |

| 20" | BTC | 533.40*269.88 | 50.10 | |

|

/ Piece | |

2,379 Pieces (Min. Order) |

###

| After-sales Service: | One Year |

|---|---|

| Warranty: | One Year |

| Manufacturing Process: | CNC Milling |

| Surface Treatment: | Spray-Paint |

| Operation Pressure: | Atmospheric Pressure |

| Material: | Alloy |

###

| Samples: |

US$ 18/Piece

1 Piece(Min.Order) |

|---|

###

|

Size and Specifications For Tubing and Casing Couplings |

||||

| Descriptions and Size | Type of Thread | O.D* L | Weight | |

| (mm) | (kg) | |||

| Tubing Coupling | 2-3/8" | NUE | 73.02*107.95 | 1.28 |

| 2-3/8" | EUE | 77.80*123.82 | 1.55 | |

| 2-7/8" | NUE | 88.90*130.18 | 2.34 | |

| 2-7/8" | EUE | 93.17*133.35 | 2.4 | |

| 3-1/2" | NUE | 107.95*142.88 | 3.71 | |

| 3-1/2" | EUE | 114.30*146.05 | 4.1 | |

| 4" | NUE | 120.65*146.05 | 4.35 | |

| 4" | EUE | 127.00*152.40 | 4.82 | |

| 4-1/2" | NUE | 132.08*155.58 | 4.89 | |

| 4-1/2" | EUE | 141.30*158.75 | 6.05 | |

| Casing Coupling | 4-1/2" | STC | 127.00*158.75 | 5.23 |

| 4-1/2" | LTC | 127.00*177.80 | 4.15 | |

| 4-1/2" | BTC | 133.35*225.42 | 6.89 | |

| 5" | STC | 147.32*165.10 | 4.66 | |

| 5" | LTC | 147.32*196.85 | 5.75 | |

| 5" | BTC | 147.32*231.78 | 5.85 | |

| 5-1/2" | STC | 153.67*171.45 | 5.23 | |

| 5-1/2" | LTC | 160.02*203.20 | 8.92 | |

| 5-1/2" | BTC | 153.67*234.95 | 6.36 | |

| 6-5/8" | STC | 187.71*184.15 | 9.12 | |

| 6-5/8" | LTC | 187.71*222.25 | 11.34 | |

| 6-5/8" | BTC | 187.71*244.48 | 11.01 | |

| 7" | STC | 194.46*184.15 | 8.39 | |

| 7" | LTC | 194.46*228.60 | 10.83 | |

| 7" | BTC | 194.46*254.00 | 10.54 | |

| 7-5/8" | STC | 215.90*190.50 | 12.3 | |

| 7-5/8" | LTC | 215.90*234.95 | 15.63 | |

| 7-5/8" | BTC | 215.90*263.52 | 15.82 | |

| 8-5/8" | STC | 244.48*196.85 | 16.23 | |

| 8-5/8" | LTC | 244.48*254.00 | 21.67 | |

| 8-5/8" | BTC | 244.48*269.88 | 20.86 | |

| 9-5/8" | STC | 269.88*196.85 | 18.03 | |

| 9-5/8" | LTC | 269.88*266.70 | 25.45 | |

| 9-5/8" | BTC | 269.88*269.88 | 23.16 | |

| 10-3/4" | STC | 298.45*203.20 | 20.78 | |

| 10-3/4" | BTC | 298.45*269.88 | 25.74 | |

| 11-3/4" | STC | 323.85*203.20 | 22.64 | |

| 11-3/4" | BTC | 323.85*269.88 | 28.03 | |

| 13-3/8" | STC | 365.12*203.20 | 25.66 | |

| 13-3/8" | BTC | 365.12*269.88 | 31.77 | |

| 16" | STC/LTC | 431.80*228.60 | 34.91 | |

| 16" | BTC | 431.80*269.88 | 40.28 | |

| 18-5/8" | STC/LTC | 508.00*228.60 | 54.01 | |

| 18-5/8" | BTC | 508.00*269.88 | 62.68 | |

| 20" | STC/LTC | 533.40*228.60 | 43.42 | |

| 20" | BTC | 533.40*269.88 | 50.10 | |

Types of Coupling

A coupling is a device used to join two shafts together and transmit power. Its primary function is to join rotating equipment and allows for some end movement and misalignment. This article discusses different types of coupling, including Magnetic coupling and Shaft coupling. This article also includes information on Overload safety mechanical coupling.

Flexible beam coupling

Flexible beam couplings are universal joints that can deal with shafts that are offset or at an angle. They consist of a tube with couplings at both ends and a thin, flexible helix in the middle. This makes them suitable for use in a variety of applications, from motion control in robotics to attaching encoders to shafts.

These couplings are made of one-piece materials and are often made of stainless steel or aluminium alloy. However, they can also be made of acetal or titanium. While titanium and acetal are less common materials, they are still suitable for high-torque applications. For more information about beam couplings, contact CZPT Components.

Flexible beam couplings come in a variety of types and sizes. W series couplings are good for general purpose applications and are relatively economical. Stainless steel versions have increased torque capacity and torsional stiffness. Flexible beam couplings made of aluminum are ideal for servo and reverse motion. They are also available with metric dimensions.

Flexible beam couplings are made of aluminum alloy or stainless steel. Their patented slot pattern provides low bearing load and high torsional rigidity. They have a long operational life. They also require zero maintenance and can handle angular offset. Their advantages outweigh the disadvantages of traditional beam couplings.

Magnetic coupling

Magnetic coupling transfers torque from one shaft to another using a magnetic field. These couplings can be used on various types of machinery. These types of transmissions are very useful in many situations, especially when you need to move large amounts of weight. The magnetic field is also very effective at reducing friction between the two shafts, which can be extremely helpful if you’re moving heavy items or machinery.

Different magnetic couplings can transmit forces either linearly or rotated. Different magnetic couplings have different topologies and can be made to transmit force in various geometric configurations. Some of these types of couplings are based on different types of materials. For example, a ceramic magnetic material can be used for applications requiring high temperature resistance.

Hybrid couplings are also available. They have a hybrid design, which allows them to operate in either an asynchronous or synchronous mode. Hysterloy is an alloy that is easily magnetized and is used in synchronous couplings. A synchronous magnetic coupling produces a coupled magnetic circuit.

Magnetic coupling is a key factor in many physical processes. In a crystal, molecules exhibit different magnetic properties, depending on their atomic configuration. Consequently, different configurations produce different amounts of magnetic coupling. The type of magnetic coupling a molecule exhibits depends on the exchange parameter Kij. This exchange parameter is calculated by using quantum chemical methods.

Magnetic couplings are most commonly used in fluid transfer pump applications, where the drive shaft is hermetically separated from the fluid. Magnetic couplings also help prevent the transmission of vibration and axial or radial loads through the drive shaft. Moreover, they don’t require external power sources, since they use permanent magnets.

Shaft coupling

A shaft coupling is a mechanical device that connects two shafts. The coupling is designed to transmit full power from one shaft to the other, while keeping the shafts in perfect alignment. It should also reduce transmission of shock loads. Ideally, the coupling should be easy to connect and maintain alignment. It should also be free of projecting parts.

The shaft couplings that are used in machines are typically made of two types: universal coupling and CZPT coupling. CZPT couplings are designed to correct for lateral misalignment and are composed of two flanges with tongues and slots. They are usually fitted with pins. The T1 tongue is fitted into flange A, while the T2 tongue fits into flange B.

Another type of shaft coupling is known as a “sliced” coupling. This type of coupling compensates for inevitable shaft misalignments and provides high torque. Machined slits in the coupling’s outer shell help it achieve high torsional stiffness and excellent flexibility. The design allows for varying engagement angles, making it ideal for many different applications.

A shaft coupling is an important component of any machine. Proper alignment of the two shafts is vital to avoid machine breakdowns. If the shafts are misaligned, extra force can be placed on other parts of the machine, causing vibration, noise, and damage to the components. A good coupling should be easy to connect and should ensure precise alignment of the shaft. Ideally, it should also have no projecting parts.

Shaft couplings are designed to tolerate a certain amount of backlash, but it must be within a system’s threshold. Any angular movement of the shaft beyond this angle is considered excessive backlash. Excessive backlash results in excessive wear, stress, and breakage, and may also cause inaccurate alignment readings. It is therefore imperative to reduce backlash before the shaft alignment process.

Overload safety mechanical coupling

Overload safety mechanical couplings are devices that automatically disengage when the torque applied to them exceeds a specified limit. They are an efficient way to protect machinery and reduce the downtime associated with repairing damaged machinery. The advantage of overload couplings is their fast reaction time and ease of installation.

Overload safety mechanical couplings can be used in a wide range of applications. Their automatic coupling mechanisms can be used on any face or edge. In addition, they can be genderless, incorporating both male and female coupling features into a single mechanism. This means that they are both safe and gender-neutral.

Overload safety couplings protect rotating power transmission components from overloads. Overload protection devices are installed on electric motors to cut off power if the current exceeds a certain limit. Likewise, fluid couplings in conveyors are equipped with melting plug elements that allow the fluid to escape when the system becomes too hot. Mechanical force transmission devices, such as shear bolts, are designed with overload protection in mind.

A common design of an overload safety mechanical coupling consists of two or more arms and hubs separated by a plastic spider. Each coupling body has a set torque threshold. Exceeding this threshold may damage the spider or damage the jaws. In addition, the spider tends to dampen vibration and absorb axial extension. This coupling style is nearly backlash free, electrically isolating, and can tolerate very little parallel misalignment.

A mechanical coupling may also be a universal joint or jaw-clutch coupling. Its basic function is to connect the driver and driven shafts, and limits torque transfer. These devices are typically used in heavy-duty industries, such as steel plants and rolling mills. They also work well with industrial conveyor systems.

CZPT Pulley

The CZPT Pulley coupling family offers a comprehensive range of couplings for motors of all types. Not only does this range include standard motor couplings, but also servo couplings, which require ultra-precise control. CZPT Pulley couplings are also suitable for engine applications where high shocks and vibrations are encountered.

CZPT Pulley couplings have a “sliced” body structure, which allows for excellent torsional stiffness and strength. They are corrosion-resistant and can withstand high rotational speeds. The couplings’ design also ensures accurate shaft rotation while limiting shaft misalignment.

CZPT Pulley has introduced the CPU Pin Type couplings, which are effective at damping vibration and maintain zero backlash. They are also made from aluminum and are capable of absorbing heat. They come with recessed tightening screws. They can handle speeds up to 4,000 RPM, and are RoHS-compliant.

editor by CX 2023-03-27

China Cushion vibration reduction and compensation axis offset Water Pump Coupling Nylon Sleeve Gear Coupling coupling bearing

Warranty: 2 many years

Applicable Industries: Creating Materials Stores, Manufacturing Plant, Equipment Mend Outlets, Meals & Beverage Factory, Retail, Development works , Vitality & Mining, Other

Custom-made assistance: OEM

Structure: Nylon sleeve

Adaptable or Rigid: Flexible

Standard or Nonstandard: Regular

Content: Nylon

Merchandise name: Nylon Sleeve Equipment Coupling

Software: Various Doing work Problems

Search term: Sleeve Gear Coupling

Measurement: A variety of spectification

Design: B24

Edge: Cushion and vibration reduction

Provider: OEM

Common: Sure

Entire body Substance: Nylon and iron

PACKING: Wooden Situation

Packaging Specifics: STHangZhouRD EXPORT PACKING

Water pump Coupling Nylon Sleeve Equipment Couplingalso transmit high torque. They are able of dislocation, normally about .01-.02 inches in parallel and about 2 levels in angle. h2o pump Coupling Nylon Sleeve Equipment Couplings are typically utilised in pairs with spacer shafts to span the length between the driving products and the driving equipment. They generally require lubricants, and some patterns for lighter programs use lubricant free of charge nylon in the middle sleeve.

Software of drinking water pump Coupling Nylon Sleeve Equipment Coupling: mechanical transmission in forging, design, mining, plastics, foods, engineering, petroleum, chemical market, Large Hardness MC Nylon Worm tooth Gear POM Plastic Small Equipment device tool, shipbuilding, leather, textile, fan, drinking water pump and other industries. The use influence of h2o pump Coupling Nylon Sleeve Equipment Coupling is obviously better than that of coupling with other buildings.

Knowledge of B24 Nylon Sleeve Equipment Coupling

| Motor size | Wilte shoft Dxl [mm] | n=750 [1/mln] PowtrP | Coupling | Tk max [Nm] | n = 1mm helical equipment rack and pinion for wooden router and engraving device which transmit torque by means of the interior gear grid of the shell assembly. The coupling sleeve with axial parallel involute equipment is centered on the tooth aspect of the coupling hub. The coupling design and style satisfies the specifications of radial and angular axial shaft displacement payment to reduce the uncontrolled added load of adjacent shaft bearings. FAQA: We are world-wide development machinery OEM manufacturer and we have been Sany,Xcmg,Liugong,Zoomlion,Cummins,Deutz,Rexroth,Parker….supplier for several years.Q: How extended is your delivery time?A: Normally it is 5-10 times if the goods are in inventory. or it is fifteen-60 times if the merchandise are not in stock, it is according to quantity.Q:How long must I hold out for the reply soon after I deliver the inquiry?A: In twelve hrs.Q:What infomation ought to I notify you to verify the merchandise?A: Model/Dimension, Shaft diameter, hole diameter&Order amount and so on.Q:What is your solution warrenty period?A:We provide 2 several years warrenty given that the vessel departure date left China.Q: What is your terms of payment ?A: Payment=1000USD, 30% T/T in progress ,harmony just before shippment.We take the LC also.

What Is a Coupling?A coupling is a mechanical device that links two shafts together and transmits power. Its purpose is to join rotating equipment while permitting a small amount of misalignment or end movement. Couplings come in a variety of different types and are used in a variety of applications. They can be used in hydraulics, pneumatics, and many other industries. TypesCoupling is a term used to describe a relationship between different modules. When a module depends on another, it can have different types of coupling. Common coupling occurs when modules share certain overall constraints. When this type of coupling occurs, any changes to the common constraint will also affect the other modules. Common coupling has its advantages and disadvantages. It is difficult to maintain and provides less control over the modules than other types of coupling. ApplicationsThe coupling function is an incredibly versatile mathematical tool that can be used in many different scientific domains. These applications range from physics and mathematics to biology, chemistry, cardio-respiratory physiology, climate science, and electrical engineering. The coupling function can also help to predict the transition from one state to another, as well as describing the functional contributions of subsystems in the system. In some cases, it can even be used to reveal the mechanisms that underlie the functionality of interactions. ProblemsA coupling is a device that connects two rotating shafts to transfer torque and rotary motion. To achieve optimal performance, a coupling must be designed for the application requirements it serves. These requirements include service, environmental, and use parameters. Otherwise, it can prematurely fail, causing inconvenience and financial loss. China UL Listed EMT Coupling 1/2″ to 4″ coupling bearingMerchandise Description

UL Listed EMT Coupling 1/2″ to 4″ one/2″ TO 4″ ALL USE STHangZhouRD SCREWS 1/4-28

Character&Dimension:

UL Listed

General: 1) Remove the inside of welded seam to insure the thread properly two) NPT standard thread, all will be taper thread three) Trade measurement: 1/2″ to 4″ four) Electro galvanized galvanized thickness fifteen micrometer,darcromet end thickness exceeding forty micrometer exceeding one hundred several hours curic dip screening 5) UL Outlined, can engrave the customer’s brand 1 the products)

Other Names: IMC coupling,threaded imc conduit coupling,Rigid couplings, threaded rigid couplings, hefty wall couplings, threaded hefty wall couplings, rigid couplers, large wall couplers, threaded couplers.conduit socket

Application:

These threaded couplings are employed to be a part of 2 finishes of threaded rigid conduits or IMC conduits together. They can also be utilized with CZPT nipples and connectors to CZPT threaded conduits to electrical junction bins or enclosures.

Why Select Ranlic Conduit Merchandise: one) High quality materials assures a finish conduit and fittings with outstanding qualities

You might decide on subsequent RanLic other Conduit products:

EMT CONDUIT PIPE

Overview

Fast Information Area of Origin: ZHangZhoug, China Brand Name: Ranlic Design Quantity: 1/2″-4″ Type: Coupling Material: Carbon Steel Technics: electro- Galvanized Link: Female Form: Equivalent Head Code: Round Size: 1/2″-4″ Regular: American regular Colour: Silver Identify: IMC conduit coupling Floor treatment method: Galvanized Certification: UL certificatiion Brand: can personalized Thickness: Standard

Source Potential Source Capability

Packaging & Shipping Guide Time:

Merchandise Description

Packaging & Shipping and delivery

Company Info

Our Companies

HangZhou Lianli Electrical Co., Ltd. Background & Purpose: We know we have the responsibility to provide the same service to our old customers and keep moving to cooperate with our potential customers. We will keep providing quality products and service. Merchandise: Marketplaces:

After 4 years’ development, Lianli has accumulated rich experience in the field.