Product Description

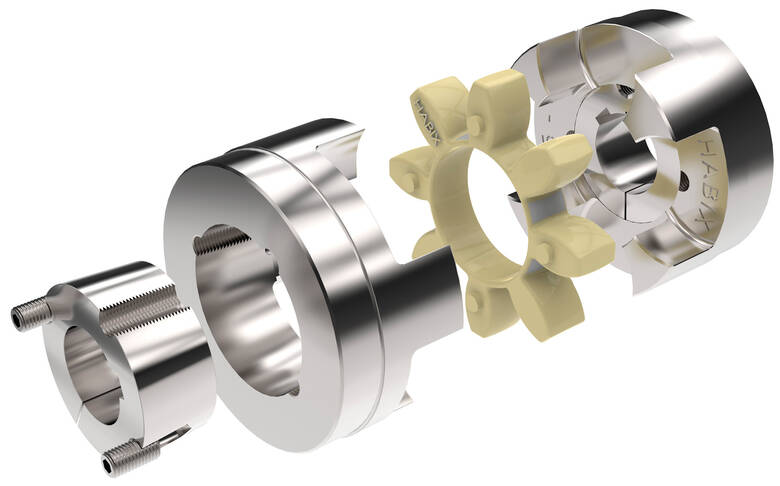

Engine Drive Elastic Rubber Coupling 48he D48407 for Atlas Compressor

Quick Details:

| Place of Origin | ZheJiang ,China(Mainland) |

| Type | Rubber Elastic Coupling |

| Available | In Stock |

| Brand Name | Y&F/YNF |

| Structure | Plastic Rubber Plastic |

| Model | 48HE 6 1/2” Coupling |

| Model Number | Rubber Elastic Coupling |

| Applican | Compressor, Construction Machines |

Packaging & Delivery:

| Packaging Details: | 1. spare parts, with carton package as usual for mini order 2. Main pump, wooden box 3. if need wooden pallets, the customer needs to pay for the wooden pallet charges Engine Drive Elastic Rubber Coupling 48HE D48407 for Atlas Compressor |

| Delivery Detail: | Shipped in 7 days after payment |

Product Description:

Engine Drive Coupling Description

–Elastic Rubber coupling for Compressors

Elastic 48HE G80HE coupling 48407

Company Information

Yingfeng Construction Machinery Ltd is a Chinese factory producing excavator parts, such as coupling, engine mount, radiator hose, cab interior, clutch, fan, exhaust manifold, intake manifold, rubber floor mat, pulley, damper, tensioner, tube, handle, oil seal, alternator, starter, water pump, etc. We also hydraulic parts, filter, engine parts, gears, bearing, undercarriage parts and OEM service.

* Biggest Excavator Rubber Parts factory in southern China. Lower production cost!

* Thousands of product lines, varies quality levels. More Choices!

* More than 16 agents all over China. Plan to expand business over the world. Agent wanted!

* More than years of manufacture experience. Professional!

* Provide customer with OEM service & various product quality levels. Help you easily sell!

* Office and showroom in HangZhou. Good logistics service!

In order to give you fast and accurate pricing information, Details about the parts will be required :

Part Number

Part Description, it will be better if you have a picture

Engine model, Machine model

Contact Information

If you can not find the parts you want, please contact us

Products Show:

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Reducing Vibration and Shock in Machinery with Elastic Couplings

Elastic couplings play a crucial role in minimizing vibration and shock in machinery by offering flexibility and damping characteristics. Here’s how they contribute to this important function:

- Vibration Absorption: Elastic couplings are designed with flexible elements that can absorb and dampen vibrations generated by rotating machinery. These flexible elements act as shock absorbers, reducing the transmission of vibrations to other parts of the system.

- Isolation: The inherent flexibility of elastic couplings isolates vibrations and shocks from one side of the coupling to the other. This prevents vibrations from propagating throughout the connected components, helping to protect sensitive equipment and improve overall system performance.

- Resonance Damping: Elastic couplings can help dampen resonance frequencies that can occur in machinery during operation. By absorbing and dissipating energy, they reduce the risk of resonance-related issues that can lead to mechanical failure or decreased efficiency.

- Smooth Torque Transmission: Elastic couplings offer a smooth torque transmission that helps reduce sudden torque spikes and shocks during start-up or sudden load changes. This prevents abrupt mechanical stresses that can lead to vibration and shock propagation.

- Increased Equipment Lifespan: By minimizing the impact of vibrations and shocks, elastic couplings contribute to the longevity of connected machinery and components. Reduced vibration-related wear and tear can extend the service life of the entire system.

Overall, elastic couplings are effective tools for managing vibration and shock in machinery, enhancing operational reliability, reducing maintenance needs, and maintaining optimal performance.

Backlash in Elastic Couplings

Backlash refers to the amount of play or clearance between mating components in a mechanical system, particularly in elastic couplings. In an elastic coupling, backlash is the angular movement or rotation that occurs when there is a change in direction of the input shaft without an immediate response from the output shaft.

Backlash is a result of the elasticity and flexibility of the coupling’s components, such as the elastomer or other flexible elements. When the input direction changes, the elastic elements need to overcome their deformation before transmitting torque to the output shaft. This delay can lead to a temporary loss of motion and reduced precision in positioning applications.

Backlash can have a negative impact on the accuracy, repeatability, and overall performance of a machinery system. It can result in positioning errors, reduced responsiveness, and even potential damage to the system. Therefore, minimizing backlash is crucial in applications that require high precision and responsiveness.

Engineers can address backlash in elastic couplings by selecting couplings with lower compliance, optimizing the design to minimize the flexibility of the coupling elements, and using additional components like anti-backlash devices or preloaded mechanisms.

Difference Between Elastic Coupling and Rigid Coupling

Elastic couplings and rigid couplings are two distinct types of couplings used in mechanical designs:

Elastic Coupling: An elastic coupling incorporates an elastomeric material, such as rubber, to provide flexibility and absorb shock and vibration. It allows for misalignment compensation and is ideal for applications where there may be slight misalignment or the need for vibration damping. Elastic couplings are commonly used in machinery that requires smooth operation and reduced stress on connected components.

Rigid Coupling: A rigid coupling, as the name suggests, is designed to provide a solid connection between two shafts. It does not have any flexible or damping elements and is used when precise alignment and torque transmission are critical. Rigid couplings are often used in applications where shafts need to maintain a constant alignment, such as in precision machines and systems with high torque requirements.

The choice between an elastic coupling and a rigid coupling depends on the specific requirements of the mechanical system, including the degree of misalignment, vibration levels, torque transmission, and the overall performance objectives.

editor by CX 2024-05-13

China factory Pump Fan Compressor Single Joint Gas Turbines Key-Joint Double Elastic Disc Flexible Shaft Lock Disc Single Diaphragm Coupling for Truck

Product Description

Pump Fan Compressor Single Joint Gas Turbines Key-Joint Double Elastic Disc Flexible Shaft Lock Disc Single Diaphragm Coupling for Truck

Metal flex couplings are disc type couplings in which several flexible metallic elements are alternately attached with bolts to opposite flanges. As polymeric elastomer is replaced by metal disc, Metal Flex coupling provides excellent temperature capability without sacrificing angular and axial misalignment. The coupling provides low axial and bending stiffness while possessing high torsional rigidity. The stretched shim pack design of CHINAMFG Metal Flex couplings provides zero backlash. CHINAMFG Metal Flex couplings are available up to 13367 Nm torque with single shim pack (UMK) and double shim pack (UMS) series.

FEATURES

1.Power to weight ratio high

2.Accommodates angular and axial misalignments

3.High temperature application

4.Visual inspection is possible without dismantling equipments

5.Low axial stiffness with high torsional rigidity

6.High-speed capacity

7.Range up to 12000 Nm

8.Added advantage of stretch fitted shim pack

|

Material Available |

Stainless Steel:SS201,SS301, SS303, SS304, SS316, SS416 etc. |

|

CNC Turning |

φ0.5 – φ300 * 750 mm,+/-0.005 mm |

|

CNC Milling |

510 * 1571 * 500 mm(max),+/-0.001 mm-+/-0.005 mm |

|

Surface Finish |

Aluminum:Clear Anodized,Color Anodized,Sandblast Anodized,Chemical Film,Brushing,Polishing,Chroming. |

|

Drawing Format |

IGS,STP,X_T ,DXF,DWG , Pro/E, PDF |

|

Test Equipment |

Measurement instrument, Projector, CMM, Altimeter, Micrometer, Thread Gages, Calipers, Pin Gauge etc. |

Production workshop:

Manufacturer of Couplings, Fluid Coupling, JAW Coupling, can interchange and replacement of lovejoy coupling and so on.

A coupling can interchange and replacement of lovejoy coupling is a device used to connect 2 shafts together at their ends for the purpose of transmitting power. The primary purpose of couplings is to join 2 pieces of rotating equipment while permitting some degree of misalignment or end movement or both. In a more general context, a coupling can also be a mechanical device that serves to connect the ends of adjacent parts or objects. Couplings do not normally allow disconnection of shafts during operation, however there are torque limiting couplings which can slip or disconnect when some torque limit is exceeded. Selection, installation and maintenance of couplings can lead to reduced maintenance time and maintenance cost.

Company information:

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Compensation for Misalignment in Elastic Couplings

Elastic couplings are designed to accommodate certain degrees of misalignment between connected components in mechanical systems. The elastomeric material used in the coupling plays a crucial role in this compensation process:

When the two components connected by the elastic coupling experience angular, parallel, or axial misalignment, the elastomeric material deforms to a certain extent. This deformation allows the coupling to maintain its connection while absorbing the misalignment-induced stresses and forces.

The elastomer acts as a flexible link between the components, allowing them to move relative to each other within specified limits. The deformation of the elastomer also helps distribute the load more evenly, reducing stress concentrations and the risk of premature wear or damage to the coupling or connected components.

Elastic couplings can compensate for both static and dynamic misalignment, making them suitable for applications where minor misalignment is unavoidable due to factors such as manufacturing tolerances, thermal expansion, or vibration.

It’s important to note that while elastic couplings can accommodate misalignment, excessive misalignment should still be avoided, as it can lead to accelerated wear and reduced coupling lifespan. Regular inspection and maintenance are recommended to ensure that the coupling is operating within its designed limits.

Advancements in Elastic Coupling Technology

Recent advancements in elastic coupling technology have led to improved performance and capabilities. Some notable developments include:

- Enhanced Materials: The use of advanced materials, such as high-performance elastomers and composites, has resulted in elastic couplings that offer higher strength, durability, and resistance to wear and fatigue.

- Optimized Designs: Engineers are employing advanced computer simulations and modeling techniques to optimize the design of elastic couplings. This has led to designs that provide better torsional flexibility, reduced backlash, and improved performance in demanding conditions.

- Vibration Dampening: Advancements in elastic coupling technology have focused on improving vibration dampening properties. This is particularly important in applications where minimizing vibration and shock is crucial for the machinery’s precision and longevity.

- Customization: Modern elastic coupling manufacturers offer more options for customization, allowing engineers to select the best coupling configuration, size, and material for their specific application requirements.

- Smart Couplings: Some elastic couplings now incorporate sensors and monitoring technology to provide real-time data on coupling performance, misalignment, and wear. This data can aid in predictive maintenance and enhance overall system reliability.

These advancements in elastic coupling technology continue to contribute to the efficiency, reliability, and overall performance of machinery systems in various industries.

Principles of Torsionally Elastic Couplings

Torsionally elastic couplings, also known as flexible couplings, operate based on the principles of flexibility and torsional elasticity. These couplings are designed to transmit torque while accommodating misalignments, dampening vibrations, and providing protection against shock loads. Here’s how they work:

- Flexibility: Torsionally elastic couplings are made of materials that can flex or bend to some degree. This flexibility allows them to absorb misalignments between connected shafts, such as angular, parallel, and axial misalignments.

- Torsional Elasticity: The material properties of the coupling allow it to twist or deform slightly under torque loads. When torque is applied to one end of the coupling, the coupling flexes and twists to transmit torque to the other end while compensating for any misalignments.

- Vibration Dampening: The torsional elasticity of the coupling helps dampen vibrations that occur due to sudden torque changes or variations in load. This is especially important in applications where smooth operation and reduced vibrations are essential.

- Shock Load Protection: Torsionally elastic couplings can absorb and mitigate shock loads that might occur during sudden starts, stops, or changes in load. This protection prevents damage to connected equipment and extends the lifespan of machinery.

Overall, torsionally elastic couplings enhance the performance, reliability, and durability of machinery by providing flexibility, dampening vibrations, and protecting against misalignments and shock loads.

editor by CX 2024-05-02

China best Connecting Parts G80he 11.5′′ Elastic Coupling for Air Compressor Excavator

Product Description

EXCAVATOR CONNECTING PARTS G80HE ELASTIC COMPRESSOR

Product Descrition:

*Place of Origin: ZheJiang , China (Mainland)

*Brand Name: CHINAMFG

*Model Number: G80HE

*Sales type: Retail, Wholesale

*Mark: According to customer needs

*Application: Construction machinery, ships, generators, compressors

*Quality: Controlstrict 100% test

*Mass production: Booking

*Available: In stock

DIMENTION:

Engine Drive Coupling TECHNICAL DATA

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Why chose us

A. 24 yease experience in the line of the market, produce high quality excavator spare parts

High quality at competitive price.

B. Factory manufacturer, factory price

C. One-stop shopping. We have Trading company based on our factory, supply with various spare parts for your need, with high quality at company price, one-stop shopping, save your time to searching the parts you need urgent.

D. Timely delivery

E. Various of transportation way: Sea, Air, Bus, Express, etc

F. Parts available in stock

Note:

A. In order to give you fast and accurate pricing information, we need some details about your engine/application and the part number of the part you want.

B. If you can not find the parts you want, please contact us

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Reducing Vibration and Shock in Machinery with Elastic Couplings

Elastic couplings play a crucial role in minimizing vibration and shock in machinery by offering flexibility and damping characteristics. Here’s how they contribute to this important function:

- Vibration Absorption: Elastic couplings are designed with flexible elements that can absorb and dampen vibrations generated by rotating machinery. These flexible elements act as shock absorbers, reducing the transmission of vibrations to other parts of the system.

- Isolation: The inherent flexibility of elastic couplings isolates vibrations and shocks from one side of the coupling to the other. This prevents vibrations from propagating throughout the connected components, helping to protect sensitive equipment and improve overall system performance.

- Resonance Damping: Elastic couplings can help dampen resonance frequencies that can occur in machinery during operation. By absorbing and dissipating energy, they reduce the risk of resonance-related issues that can lead to mechanical failure or decreased efficiency.

- Smooth Torque Transmission: Elastic couplings offer a smooth torque transmission that helps reduce sudden torque spikes and shocks during start-up or sudden load changes. This prevents abrupt mechanical stresses that can lead to vibration and shock propagation.

- Increased Equipment Lifespan: By minimizing the impact of vibrations and shocks, elastic couplings contribute to the longevity of connected machinery and components. Reduced vibration-related wear and tear can extend the service life of the entire system.

Overall, elastic couplings are effective tools for managing vibration and shock in machinery, enhancing operational reliability, reducing maintenance needs, and maintaining optimal performance.

Impact of Temperature Variations on Elastic Coupling Performance

Elastic couplings can be sensitive to temperature variations, and their performance can be influenced by both high and low temperatures:

1. High Temperatures: Elevated temperatures can cause the elastomeric material used in elastic couplings to soften, leading to a decrease in its mechanical properties. This can result in reduced torsional stiffness, damping capabilities, and overall coupling performance. High temperatures can also accelerate the aging process of the elastomer, leading to a shorter lifespan of the coupling. Additionally, excessive heat can cause thermal expansion of the coupling’s components, potentially leading to misalignment issues.

2. Low Temperatures: Extremely low temperatures can cause the elastomeric material to become more rigid, reducing its flexibility and damping characteristics. This can result in increased transmission of vibrations and shocks between connected components. Cold temperatures can also make the elastomer more brittle, increasing the risk of cracking or rupturing under mechanical stress.

It’s important to select an elastic coupling material that is suitable for the anticipated temperature range of the application. Some elastomers are formulated to perform well across a wide temperature range, while others are better suited for specific temperature conditions. Regular maintenance and inspection of elastic couplings in extreme temperature environments are crucial to ensure that the coupling continues to function as intended.

Elastic Coupling: Function and Working in Mechanical Systems

An elastic coupling is a type of coupling used in mechanical systems to connect two shafts and transmit torque while allowing for a certain degree of misalignment and flexibility. It consists of two hubs, each connected to a shaft, and an elastic element placed between the hubs.

The elastic element, often made of rubber or elastomer material, serves as a flexible medium that can absorb shocks, vibrations, and angular misalignments between the connected shafts. When torque is applied to one shaft, the elastic element deforms and compresses, allowing the coupling to transmit torque from one shaft to the other while compensating for minor misalignments.

As the elastic element absorbs vibrations and shocks, it helps reduce wear and tear on the connected machinery and enhances overall system efficiency. Elastic couplings are commonly used in applications where precise alignment between shafts is challenging or where vibration damping is crucial.

Overall, the elastic coupling’s design enables it to provide a balance between torque transmission and flexibility, making it a valuable component in various mechanical systems.

editor by CX 2024-04-12

China Standard Pump Fan Compressor Single Joint Gas Turbines Key-Joint Double Elastic Disc Flexible Shaft Lock Disc Single Diaphragm Coupling for Truck

Product Description

Pump Fan Compressor Single Joint Gas Turbines Key-Joint Double Elastic Disc Flexible Shaft Lock Disc Single Diaphragm Coupling for Truck

Metal flex couplings are disc type couplings in which several flexible metallic elements are alternately attached with bolts to opposite flanges. As polymeric elastomer is replaced by metal disc, Metal Flex coupling provides excellent temperature capability without sacrificing angular and axial misalignment. The coupling provides low axial and bending stiffness while possessing high torsional rigidity. The stretched shim pack design of CHINAMFG Metal Flex couplings provides zero backlash. CHINAMFG Metal Flex couplings are available up to 13367 Nm torque with single shim pack (UMK) and double shim pack (UMS) series.

FEATURES

1.Power to weight ratio high

2.Accommodates angular and axial misalignments

3.High temperature application

4.Visual inspection is possible without dismantling equipments

5.Low axial stiffness with high torsional rigidity

6.High-speed capacity

7.Range up to 12000 Nm

8.Added advantage of stretch fitted shim pack

|

Material Available |

Stainless Steel:SS201,SS301, SS303, SS304, SS316, SS416 etc. |

|

CNC Turning |

φ0.5 – φ300 * 750 mm,+/-0.005 mm |

|

CNC Milling |

510 * 1571 * 500 mm(max),+/-0.001 mm-+/-0.005 mm |

|

Surface Finish |

Aluminum:Clear Anodized,Color Anodized,Sandblast Anodized,Chemical Film,Brushing,Polishing,Chroming. |

|

Drawing Format |

IGS,STP,X_T ,DXF,DWG , Pro/E, PDF |

|

Test Equipment |

Measurement instrument, Projector, CMM, Altimeter, Micrometer, Thread Gages, Calipers, Pin Gauge etc. |

Production workshop:

Manufacturer of Couplings, Fluid Coupling, JAW Coupling, can interchange and replacement of lovejoy coupling and so on.

A coupling can interchange and replacement of lovejoy coupling is a device used to connect 2 shafts together at their ends for the purpose of transmitting power. The primary purpose of couplings is to join 2 pieces of rotating equipment while permitting some degree of misalignment or end movement or both. In a more general context, a coupling can also be a mechanical device that serves to connect the ends of adjacent parts or objects. Couplings do not normally allow disconnection of shafts during operation, however there are torque limiting couplings which can slip or disconnect when some torque limit is exceeded. Selection, installation and maintenance of couplings can lead to reduced maintenance time and maintenance cost.

Company information:

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Maintenance Requirements for Optimal Performance of Elastic Couplings

Maintaining elastic couplings is essential to ensure their optimal performance and longevity. Following these maintenance guidelines can help prevent premature wear and failure:

- Regular Inspection: Periodically inspect the coupling for signs of wear, such as cracks, deformities, or visible damage. This can help identify issues early and prevent further damage.

- Lubrication: Some elastic couplings require lubrication to reduce friction and wear. Follow the manufacturer’s recommendations for lubrication intervals and use compatible lubricants.

- Torque Check: Check the coupling’s torque values to ensure they are within the specified range. This helps maintain proper torque transmission and prevents overloading.

- Alignment Check: Monitor the alignment of the connected shafts regularly. Misalignment can cause excessive stress on the coupling, leading to premature failure.

- Vibration Analysis: Perform vibration analysis to identify any abnormal vibrations in the system. Excessive vibrations could indicate coupling or system issues that need attention.

- Temperature and Environment: Ensure that the coupling operates within the recommended temperature and environmental limits. Extreme conditions can affect the coupling’s material properties and performance.

- Coupling Wear: Keep track of the coupling’s wear over time. Depending on the application, the coupling might need replacement after a certain period of service.

- Expert Inspection: If any unusual symptoms or problems arise, consider having the coupling inspected by a qualified technician or engineer to diagnose the issue accurately.

Adhering to these maintenance practices helps extend the service life of elastic couplings, ensures reliable performance, and minimizes unexpected downtime and costly repairs.

Backlash in Elastic Couplings

Backlash refers to the amount of play or clearance between mating components in a mechanical system, particularly in elastic couplings. In an elastic coupling, backlash is the angular movement or rotation that occurs when there is a change in direction of the input shaft without an immediate response from the output shaft.

Backlash is a result of the elasticity and flexibility of the coupling’s components, such as the elastomer or other flexible elements. When the input direction changes, the elastic elements need to overcome their deformation before transmitting torque to the output shaft. This delay can lead to a temporary loss of motion and reduced precision in positioning applications.

Backlash can have a negative impact on the accuracy, repeatability, and overall performance of a machinery system. It can result in positioning errors, reduced responsiveness, and even potential damage to the system. Therefore, minimizing backlash is crucial in applications that require high precision and responsiveness.

Engineers can address backlash in elastic couplings by selecting couplings with lower compliance, optimizing the design to minimize the flexibility of the coupling elements, and using additional components like anti-backlash devices or preloaded mechanisms.

Industries Using Elastic Couplings

Elastic couplings find extensive use in various industries due to their unique benefits:

- Industrial Manufacturing: Elastic couplings are widely used in manufacturing equipment, conveyors, and assembly lines to maintain smooth operation and reduce vibrations.

- Automotive: Automotive applications include engine components, powertrain systems, and vehicle suspension systems where flexibility and vibration dampening are crucial.

- Power Generation: Elastic couplings are used in power generation equipment such as generators, turbines, and pumps to absorb torsional vibrations and enhance efficiency.

- Aerospace: In aerospace applications, elastic couplings help dampen vibrations in critical components like aircraft engines and control systems.

- Renewable Energy: Wind turbines and solar tracking systems benefit from elastic couplings to accommodate misalignments and vibrations caused by changing wind conditions.

- Mining: Mining equipment such as crushers, conveyors, and screens utilize elastic couplings to handle varying loads and minimize shock loads.

- Marine: Elastic couplings are used in marine propulsion systems and ship equipment to manage torque fluctuations and reduce vibrations.

These industries rely on elastic couplings to enhance performance, extend machinery lifespan, and minimize downtime due to vibrations, misalignments, and shock loads.

editor by CX 2024-04-11

China manufacturer 1604076100 Elastic Coupling Rubber Coupling Suitable for Xas97 Mobile Air Compressor

Product Description

| Product presentation |

| 16040761+ last 6 months only Alibaba , this is the first in all of the compressor spare parts and filter company in China(offical data from Alibaba )

2. Business level is 3 Diamonds , this is first in all of the compressor spare parts and 3. We got the most of praise of good seller in the Alibaba , 13 years specialized compressor filter and 8 years spare parts production and export to more than 120 countries, the number of praise from client is first in all of the compressor spare parts and filter company in China(offical data from Alibaba ) 4 . Alibaba provide USD 26000 payment value guarantee for client , it means if our goods have any quality problem , Alibaba will provide MAX USD 26000 compensation to you . |

| More than 14 years , we establish thorough Sales network in China , won the excellent reputation .At the same time we start from the company export business in 2013 and have rapid development ,now exported more than 10 years ,won the appreciation of customers more than 70 Countries . |

| FAQ |

| 1.Price: |

| All prices and terms are quoted in US Dollar under FOB HangZhou or CIF your country port , and the price available for 1 months. |

| 2. Minimum Order Quantity: |

| Each item has a minimum order quantity, which would be stated in our quote sheet. Assorted items would be negotiable. |

| 3.Delivery Lead Time: |

| If there have stocks, the lead time is about 1 week after we get the payment, if need producing ,7 days after we get the prepay CHINAMFG request. |

| 4. Payment Terms: |

| T/T , Western Union , PayPal . |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Material Selection and Design Durability of Elastic Couplings

The choice of materials for elastic couplings significantly influences their design and overall durability. Material selection affects factors such as flexibility, torsional stiffness, fatigue resistance, and resistance to environmental conditions. Here’s how material selection plays a crucial role:

- Elastomer Material: The elastomer used in elastic couplings determines the coupling’s flexibility, vibration absorption capabilities, and resilience. Common elastomers include natural rubber, synthetic rubber, and polyurethane. The selected elastomer should provide the desired level of elasticity and durability while maintaining its properties over time.

- Hub and Spacer Material: The hubs and spacers of elastic couplings are typically made from metals like steel, aluminum, or alloy materials. These components need to be strong enough to transmit torque while accommodating misalignments and vibrations. The material should also resist wear, corrosion, and fatigue.

- Bolt or Pin Material: Bolts or pins used to connect the hubs and elastomer element must possess sufficient strength to handle the torsional forces and loads. They should be made from materials with high tensile strength and corrosion resistance.

- Environmental Factors: Depending on the application environment, material selection should consider factors such as temperature, moisture, chemicals, and UV exposure. The chosen materials should be able to withstand these conditions without deterioration.

Ultimately, a well-considered material selection enhances the coupling’s durability, operational performance, and resistance to wear, ensuring that the elastic coupling can reliably function under varying conditions and loads.

Alternatives to Elastic Couplings for Flexible Connections in Machinery

There are several alternatives to elastic couplings for achieving flexible connections in machinery:

1. Universal Joints: Universal joints, also known as U-joints, are mechanical devices that allow rotational motion between two shafts at different angles. They are suitable for applications with significant misalignment.

2. Cardan Shafts: Cardan shafts consist of a series of universal joints connected in a line, allowing for the transmission of torque and rotation in complex systems.

3. Oldham Couplings: Oldham couplings use sliding disks to transmit torque while accommodating small misalignments. They are suitable for applications where precise positioning is required.

4. Beam Couplings: Beam couplings use a flexible beam to transmit torque and compensate for angular and axial misalignment.

5. Diaphragm Couplings: Diaphragm couplings use thin diaphragms to transmit torque while compensating for misalignment. They are often used in high-performance applications.

6. Gear Couplings: Gear couplings use teethed gears to transmit torque and accommodate misalignment. They are suitable for heavy-duty applications.

7. Chain Couplings: Chain couplings use roller chains to transmit torque and handle misalignment. They are commonly used in low-speed, high-torque applications.

8. Bellows Couplings: Bellows couplings use a bellows-like flexible element to transmit torque while compensating for misalignment.

Each of these alternatives has its own advantages and limitations, and the choice depends on the specific requirements of the application.

Types of Elastic Couplings for Specific Applications

There are various types of elastic couplings available, each designed to suit specific industrial applications:

- Flexible Jaw Couplings: These couplings use an elastomeric element to transmit torque and accommodate misalignment. They are commonly used in applications where shock absorption and vibration damping are important, such as pumps, compressors, and conveyor systems.

- Diaphragm Couplings: Diaphragm couplings use thin metal diaphragms to transmit torque while allowing for angular, axial, and radial misalignment. They are often used in high-performance applications where precise motion transmission is required, such as in robotics, precision machinery, and aerospace systems.

- Torsional Couplings: Torsional couplings are designed to handle high torque loads and are commonly used in heavy-duty applications, including industrial machinery, mining equipment, and large pumps.

- Disc Couplings: Disc couplings use multiple thin metal discs to transmit torque and accommodate misalignment. They are suitable for applications requiring high torque transmission and precise motion control, such as turbines, generators, and high-speed machinery.

- Beam Couplings: Beam couplings use helical cuts in a flexible beam to provide torsional flexibility and misalignment compensation. They are used in applications that require moderate torque transmission and misalignment accommodation, such as stepper motors and motion control systems.

- Oldham Couplings: Oldham couplings use three disks to transmit torque while allowing for axial misalignment. They are commonly used in applications that require accurate motion transmission, such as linear actuators and CNC machinery.

The choice of the right type of elastic coupling depends on factors such as the application’s torque requirements, speed, misalignment characteristics, and specific performance needs.

editor by CX 2024-03-28

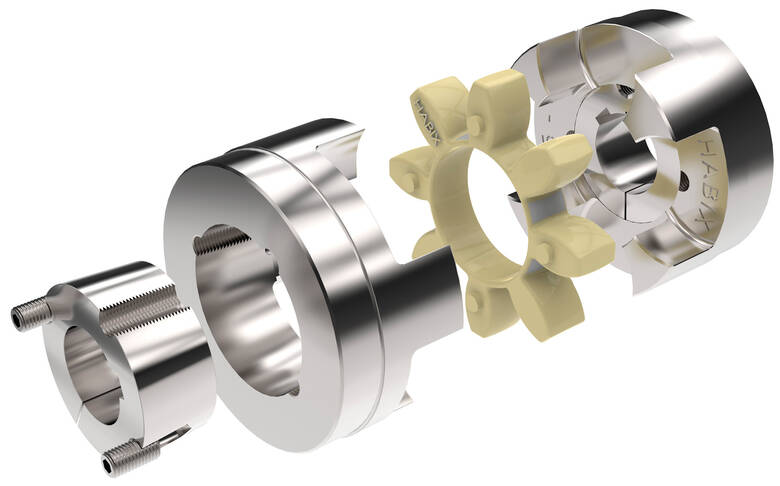

China supplier Elastic Rubber Coupling for Air Compressor

Product Description

Quick Details

Place of Origin: ZheJiang , China (Mainland)

Brand Name: CHINAMFG

Model Number: ELASTIC rubber coupling G80HE rubber coupling

Application: Construction machines

Engine Model 1: for Hatz 2L/3L/4L41C 2M/3M/4M41

Engine Model 2: for Hatz W35

Engine Model 3: for Hatz 1D81/1D90 Z788/Z789/Z790

Model: ELASTIC rubber coupling G80HE rubber coupling

Machines: Excavators, bulldozers, Wheel loader flange

Description: Engine Drive Coupling

Material: Rubber, PA6

Coupling assy: Element,

HPV102, 8DC8 8DC9, TierII 522192, 60, 1,

385, 396, 415, 416, 455, 485,

VIO75, VIO70, 172187-712, 4DNV98

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Compensation for Misalignment in Elastic Couplings

Elastic couplings are designed to accommodate certain degrees of misalignment between connected components in mechanical systems. The elastomeric material used in the coupling plays a crucial role in this compensation process:

When the two components connected by the elastic coupling experience angular, parallel, or axial misalignment, the elastomeric material deforms to a certain extent. This deformation allows the coupling to maintain its connection while absorbing the misalignment-induced stresses and forces.

The elastomer acts as a flexible link between the components, allowing them to move relative to each other within specified limits. The deformation of the elastomer also helps distribute the load more evenly, reducing stress concentrations and the risk of premature wear or damage to the coupling or connected components.

Elastic couplings can compensate for both static and dynamic misalignment, making them suitable for applications where minor misalignment is unavoidable due to factors such as manufacturing tolerances, thermal expansion, or vibration.

It’s important to note that while elastic couplings can accommodate misalignment, excessive misalignment should still be avoided, as it can lead to accelerated wear and reduced coupling lifespan. Regular inspection and maintenance are recommended to ensure that the coupling is operating within its designed limits.

Maintaining the Longevity of Elastic Couplings

Ensuring the longevity and optimal performance of elastic couplings requires proper maintenance and care. Here are some key considerations:

- Regular Inspection: Periodically inspect the coupling for signs of wear, damage, or misalignment. Look for cracks, tears, or other deformations in the elastic elements.

- Lubrication: Some elastic couplings require lubrication for smooth operation. Follow the manufacturer’s guidelines on lubrication intervals and recommended lubricants.

- Environmental Conditions: Consider the operating environment of the coupling. Extreme temperatures, chemicals, moisture, and other factors can affect the coupling’s lifespan. Choose materials and designs suitable for the specific conditions.

- Proper Alignment: Ensure that the connected components are properly aligned to minimize excessive stress on the coupling. Misalignment can accelerate wear and reduce performance.

- Load Capacity: Do not exceed the coupling’s recommended torque and load ratings. Overloading the coupling can lead to premature failure.

- Shock and Vibration: If the system experiences frequent shock or vibration, consider using dampening or vibration-absorbing components to reduce the stress on the coupling.

- Replacement: When signs of wear or damage become noticeable, promptly replace the coupling to avoid further issues. Delaying replacement can lead to more significant problems in the machinery system.

- Follow Manufacturer Guidelines: Always follow the manufacturer’s recommendations for installation, operation, and maintenance of the specific coupling model.

By adhering to these considerations and performing regular maintenance tasks, engineers can extend the lifespan of elastic couplings and ensure reliable and efficient operation in various machinery applications.

Industries Using Elastic Couplings

Elastic couplings find extensive use in various industries due to their unique benefits:

- Industrial Manufacturing: Elastic couplings are widely used in manufacturing equipment, conveyors, and assembly lines to maintain smooth operation and reduce vibrations.

- Automotive: Automotive applications include engine components, powertrain systems, and vehicle suspension systems where flexibility and vibration dampening are crucial.

- Power Generation: Elastic couplings are used in power generation equipment such as generators, turbines, and pumps to absorb torsional vibrations and enhance efficiency.

- Aerospace: In aerospace applications, elastic couplings help dampen vibrations in critical components like aircraft engines and control systems.

- Renewable Energy: Wind turbines and solar tracking systems benefit from elastic couplings to accommodate misalignments and vibrations caused by changing wind conditions.

- Mining: Mining equipment such as crushers, conveyors, and screens utilize elastic couplings to handle varying loads and minimize shock loads.

- Marine: Elastic couplings are used in marine propulsion systems and ship equipment to manage torque fluctuations and reduce vibrations.

These industries rely on elastic couplings to enhance performance, extend machinery lifespan, and minimize downtime due to vibrations, misalignments, and shock loads.

editor by CX 2024-03-26

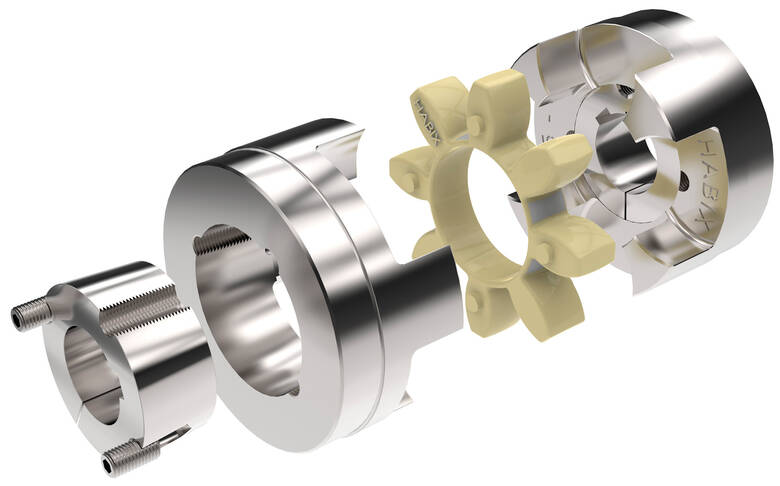

China Good quality Elastic Rubber Coupling for Air Compressor

Product Description

Quick Details

Place of Origin: ZheJiang , China (Mainland)

Brand Name: Y&F

Model Number: ELASTIC rubber coupling G80HE rubber coupling

Application: Construction machines

Engine Model 1: for Hatz 2L/3L/4L41C 2M/3M/4M41

Engine Model 2: for Hatz W35

Engine Model 3: for Hatz 1D81/1D90 Z788/Z789/Z790

Model: ELASTIC rubber coupling G80HE rubber coupling

Machines: Excavators, bulldozers, Wheel loader flange

Description: Engine Drive Coupling

Material: Rubber, PA6

Coupling assy: Element,

HPV102, 8DC8 8DC9, TierII 522192, 60, 1,

385, 396, 415, 416, 455, 485,

VIO75, VIO70, 172187-712, 4DNV98

Reducing Vibration and Shock in Machinery with Elastic Couplings

Elastic couplings play a crucial role in minimizing vibration and shock in machinery by offering flexibility and damping characteristics. Here’s how they contribute to this important function:

- Vibration Absorption: Elastic couplings are designed with flexible elements that can absorb and dampen vibrations generated by rotating machinery. These flexible elements act as shock absorbers, reducing the transmission of vibrations to other parts of the system.

- Isolation: The inherent flexibility of elastic couplings isolates vibrations and shocks from one side of the coupling to the other. This prevents vibrations from propagating throughout the connected components, helping to protect sensitive equipment and improve overall system performance.

- Resonance Damping: Elastic couplings can help dampen resonance frequencies that can occur in machinery during operation. By absorbing and dissipating energy, they reduce the risk of resonance-related issues that can lead to mechanical failure or decreased efficiency.

- Smooth Torque Transmission: Elastic couplings offer a smooth torque transmission that helps reduce sudden torque spikes and shocks during start-up or sudden load changes. This prevents abrupt mechanical stresses that can lead to vibration and shock propagation.

- Increased Equipment Lifespan: By minimizing the impact of vibrations and shocks, elastic couplings contribute to the longevity of connected machinery and components. Reduced vibration-related wear and tear can extend the service life of the entire system.

Overall, elastic couplings are effective tools for managing vibration and shock in machinery, enhancing operational reliability, reducing maintenance needs, and maintaining optimal performance.

Impact of Temperature Variations on Elastic Coupling Performance

Elastic couplings can be sensitive to temperature variations, and their performance can be influenced by both high and low temperatures:

1. High Temperatures: Elevated temperatures can cause the elastomeric material used in elastic couplings to soften, leading to a decrease in its mechanical properties. This can result in reduced torsional stiffness, damping capabilities, and overall coupling performance. High temperatures can also accelerate the aging process of the elastomer, leading to a shorter lifespan of the coupling. Additionally, excessive heat can cause thermal expansion of the coupling’s components, potentially leading to misalignment issues.

2. Low Temperatures: Extremely low temperatures can cause the elastomeric material to become more rigid, reducing its flexibility and damping characteristics. This can result in increased transmission of vibrations and shocks between connected components. Cold temperatures can also make the elastomer more brittle, increasing the risk of cracking or rupturing under mechanical stress.

It’s important to select an elastic coupling material that is suitable for the anticipated temperature range of the application. Some elastomers are formulated to perform well across a wide temperature range, while others are better suited for specific temperature conditions. Regular maintenance and inspection of elastic couplings in extreme temperature environments are crucial to ensure that the coupling continues to function as intended.

Industries Using Elastic Couplings

Elastic couplings find extensive use in various industries due to their unique benefits:

- Industrial Manufacturing: Elastic couplings are widely used in manufacturing equipment, conveyors, and assembly lines to maintain smooth operation and reduce vibrations.

- Automotive: Automotive applications include engine components, powertrain systems, and vehicle suspension systems where flexibility and vibration dampening are crucial.

- Power Generation: Elastic couplings are used in power generation equipment such as generators, turbines, and pumps to absorb torsional vibrations and enhance efficiency.

- Aerospace: In aerospace applications, elastic couplings help dampen vibrations in critical components like aircraft engines and control systems.

- Renewable Energy: Wind turbines and solar tracking systems benefit from elastic couplings to accommodate misalignments and vibrations caused by changing wind conditions.

- Mining: Mining equipment such as crushers, conveyors, and screens utilize elastic couplings to handle varying loads and minimize shock loads.

- Marine: Elastic couplings are used in marine propulsion systems and ship equipment to manage torque fluctuations and reduce vibrations.

These industries rely on elastic couplings to enhance performance, extend machinery lifespan, and minimize downtime due to vibrations, misalignments, and shock loads.

editor by CX 2023-11-16

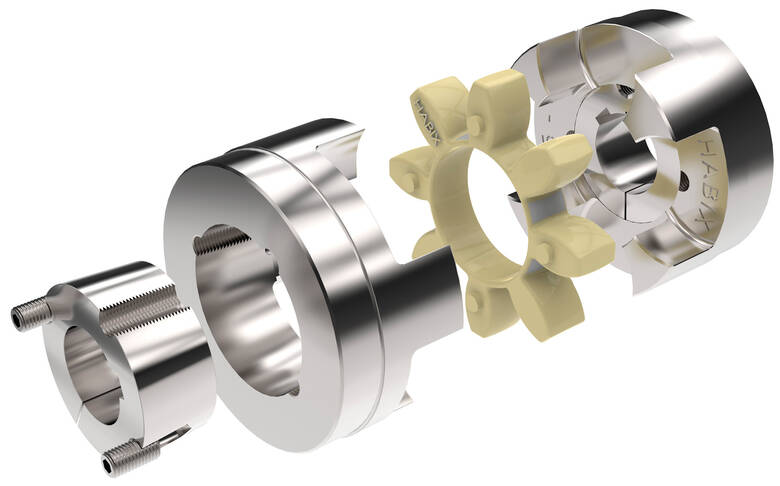

China factory Elastic Rubber Coupling for Air Compressor

Product Description

Quick Details

Place of Origin: ZheJiang , China (Mainland)

Brand Name: Y&F

Model Number: ELASTIC rubber coupling G80HE rubber coupling

Application: Construction machines

Engine Model 1: for Hatz 2L/3L/4L41C 2M/3M/4M41

Engine Model 2: for Hatz W35

Engine Model 3: for Hatz 1D81/1D90 Z788/Z789/Z790

Model: ELASTIC rubber coupling G80HE rubber coupling

Machines: Excavators, bulldozers, Wheel loader flange

Description: Engine Drive Coupling

Material: Rubber, PA6

Coupling assy: Element,

HPV102, 8DC8 8DC9, TierII 522192, 60, 1,

385, 396, 415, 416, 455, 485,

VIO75, VIO70, 172187-712, 4DNV98

Real-World Applications of Elastic Couplings

Elastic couplings find extensive use in various industries and applications where the reduction of vibration and shock is critical for performance, efficiency, and equipment longevity. Here are some examples:

- Industrial Machinery: Elastic couplings are commonly employed in industrial machinery such as pumps, compressors, conveyors, and generators. They help minimize vibration and shock, ensuring smooth and reliable operation while protecting sensitive components.

- Automotive Industry: In automotive applications, elastic couplings are used in drivetrains to dampen vibrations and shocks between the engine and the transmission. This enhances driving comfort, reduces noise, and prevents excessive wear on connected components.

- Power Generation: Power generation equipment, including turbines and generators, benefits from elastic couplings that absorb torsional vibrations and shocks. This aids in maintaining stable power output and extending the lifespan of critical components.

- Printing and Packaging: Printing presses and packaging machinery rely on elastic couplings to reduce vibrations during high-speed operations. This ensures precise printing and packaging while preventing damage to sensitive components.

- Robotics and Automation: Elastic couplings are crucial in robotics and automation systems to mitigate vibrations and shocks that can affect accuracy and reliability. They enable precise movement control and consistent performance.

- Medical Equipment: Medical devices such as MRI machines and X-ray equipment utilize elastic couplings to minimize vibrations that could impact image quality and precision during medical procedures.

These examples highlight how elastic couplings contribute to optimal performance, reduced maintenance, and increased equipment lifespan across diverse industries.

Advancements in Elastic Coupling Technology

Recent advancements in elastic coupling technology have led to improved performance and capabilities. Some notable developments include:

- Enhanced Materials: The use of advanced materials, such as high-performance elastomers and composites, has resulted in elastic couplings that offer higher strength, durability, and resistance to wear and fatigue.

- Optimized Designs: Engineers are employing advanced computer simulations and modeling techniques to optimize the design of elastic couplings. This has led to designs that provide better torsional flexibility, reduced backlash, and improved performance in demanding conditions.

- Vibration Dampening: Advancements in elastic coupling technology have focused on improving vibration dampening properties. This is particularly important in applications where minimizing vibration and shock is crucial for the machinery’s precision and longevity.

- Customization: Modern elastic coupling manufacturers offer more options for customization, allowing engineers to select the best coupling configuration, size, and material for their specific application requirements.

- Smart Couplings: Some elastic couplings now incorporate sensors and monitoring technology to provide real-time data on coupling performance, misalignment, and wear. This data can aid in predictive maintenance and enhance overall system reliability.

These advancements in elastic coupling technology continue to contribute to the efficiency, reliability, and overall performance of machinery systems in various industries.

Industries Using Elastic Couplings

Elastic couplings find extensive use in various industries due to their unique benefits:

- Industrial Manufacturing: Elastic couplings are widely used in manufacturing equipment, conveyors, and assembly lines to maintain smooth operation and reduce vibrations.

- Automotive: Automotive applications include engine components, powertrain systems, and vehicle suspension systems where flexibility and vibration dampening are crucial.

- Power Generation: Elastic couplings are used in power generation equipment such as generators, turbines, and pumps to absorb torsional vibrations and enhance efficiency.

- Aerospace: In aerospace applications, elastic couplings help dampen vibrations in critical components like aircraft engines and control systems.

- Renewable Energy: Wind turbines and solar tracking systems benefit from elastic couplings to accommodate misalignments and vibrations caused by changing wind conditions.

- Mining: Mining equipment such as crushers, conveyors, and screens utilize elastic couplings to handle varying loads and minimize shock loads.

- Marine: Elastic couplings are used in marine propulsion systems and ship equipment to manage torque fluctuations and reduce vibrations.

These industries rely on elastic couplings to enhance performance, extend machinery lifespan, and minimize downtime due to vibrations, misalignments, and shock loads.

editor by CX 2023-11-16

China Best Sales Flexible Plastic Coupling for Screw Air Compressor Parts types of coupling

Product Description

| Product information |

GR65 100HP red color coupling flexible connection made in HangZhou jiubei

Star plum CZPT pad coupling elastomer GR65 8 angle glue

Air Compressor flexible coupling rubber coupling element GR65

GR19

GR24

GR28

GR38

GR42

GR48

GR55

GR65

GR 75

GR90

GR 100

GR 110

Quick Details

Place of Origin:

ZheJiang , China (Mainland)

Brand Name:

OEM

Application:

Screw Air Compressor

Material:

rubber

Dimension:

8*10*10cm

Weight:

0.1kg

MOQ:

1pc

Package:

neutral packing

Color:

red

Warranty:

1 Year

Delivery Time:

1-3 working days after received your payment

Type:

GR24//38/42/65/75 Rubber Coupling

Supply Ability

Supply Ability:

10000 Piece/Pieces per Month

Packaging & Delivery

Packaging Details

Package each product with blank packing for Rubber coupling

Delivery Time

1-3 working days after received your payment for Rubber coupling

Port

HangZhou,hongkong port

They have excellent vibration dampening capability and high-misalignment capacity, providing extended life to connected equipment. The couplings offer a replace-in-place design for quick installation and replacement.

Feature •

Avoiding impulsive load, high efficient driving and reliable operation • Install or remove the element radially and eady of maintenance for shaft seal

Procedure of flexible coupling

Claw type surface to surface design, has the function of protecting, vibration and shock can produce effective damping and reduce the running in process. Claw type teeth 2 sleeve are offset in the circumferential direction, in the gap in a quincunx elastic body of involute. When small deviations in the installation, the elastic body avoids the stress concentration. Can effectively compensate the axial, radial and angular displacement. Column pin coupling elastomer old-fashioned type of large volume, shear effect, easy to damage, while the elastic body new claw type couplings only under the extrusion pressure, so it can withstand greater load, better wear resistance, longer service life. And both the level of installation, and can be installed vertical.

Characteristics of coupling products:

1, Has the advantages of simple structure, stable performance, stable operation

2, Three component structure, easy installation and maintenance.

3, Hub and elastic body, a variety of materials to choose from, to ensure that all can work stably in various environments.

4, Using a surface matching claw type shaft hub and involute arc elasticity, can avoid the stress concentration, the effective transmission of higher torque, more resistant to abrasion, longer service life. A small protuberance pad 5 elastic body, can isolate the metal shaft hub contact in coupling installed, effective insulation, no need of lubrication. Coupling of deviation of the remedy is deformation occurs through the elastic force at the finish.

Features

1, We can provide OEM service of het exchangers totally according to customers’requirement.

2, We can print logo according to buyers’ requirement.

3, We have been qualified by ISO9001:2000 since 2004. 4

, We has exported to many countries, such as Korea, USA, etc.

| Specification |

screw air compressor flexible coupling

with high quality and low price

Material:Rubber

| Businesss scope |

| Business scope | ||

| Mechanical Seal : |

Temperature Sensor | Pressure Sensor |

| Maintenance Kits | Solenoid Valve | Thermostatic Valve |

| Air intake | Wheel Gear |

Pressure Maintaining Valve |

| Air Filter | Oil Separator | Oil Filter |

| Oil Level Indicator | Circuit Board Master Control | Air intake valve |

| Used air compressor | Air-end | Oil level indicator |

| Additional information |

| No | Model | Gas displacement m3/min | Power(kw) | |||

| 7.5bar | 8.5/8bar | 10bar | 13bar | |||

| 1 | GA5P FM | 0.9 | 0.8 | 0.7 | 0.5 | 5 |

| 2 | GA7P FM | 1.2 | 1.1 | 1 | 0.8 | 7 |

| 3 | GA11P FM | 1.7 | 1.6 | 1.5 | 1.2 | 11 |

| 4 | GXe15P FM | 2.58 | 2.36 | 2.18 | 1.81 | 15 |

| 5 | GXe18P FM | 3.15 | 3.01 | 2.61 | 2.23 | 18 |

| 6 | GXe22P FM | 3.61 | 3.5 | 3.1 | 2.7 | 22 |

| 7 | GAe11P | 2 | 1.9 | 1.6 | 1.2 | 11 |

| 8 | GAe15P | 2.7 | 2.5 | 2.3 | 1.9 | 15 |

| 9 | GAe18P | 3.3 | 3.1 | 2.7 | 2.3 | 18 |

| 10 | GAe22P | 3.8 | 3.7 | 3.3 | 2.8 | 22 |

| 11 | GAe26P | 4.3 | 4 | 3.7 | 3.1 | 26 |

| 12 | GAe30P | 4.8 | 4.5 | 4.3 | 3.7 | 30 |

| 13 | GA11+P | 2.1 | 2 | 1.8 | 1.5 | 11 |

| 14 | GA15+P | 2.8 | 2.6 | 2.4 | 2 | 15 |

| 15 | GA18+P | 3.5 | 3.3 | 2.9 | 2.5 | 18 |

| 16 | GA22+P | 4.1 | 3.9 | 3.5 | 3 | 22 |

| 17 | GA26+P | 4.8 | 4.6 | 4.2 | 3.6 | 26 |

| 18 | GA30P | 5.4 | 5.2 | 4.8 | 4.1 | 30 |

| 19 | GA30+AP | 6.1 | 6.0(8bar) | 4.8 | 3.9 | 30 |

| 20 | GA37AP | 6.4 | 6.3(8bar) | 5.6 | 4.5 | 37 |

| 21 | GA37+AP | 7.1 | 6.9(8bar) | 5.9 | 4.9 | 37 |

| 22 | GA45AP | 7.7 | 7.3(8bar) | 6.5 | 5.5 | 45 |

| 23 | GA45+AP | 8.6 | 8.0(8bar) | 7.3 | 6.1 | 45 |

| 24 | GA55AP | 10 | 9.3(8bar) | 8.6 | 7.4 | 55 |

| 25 | GA55+(A/W)P | 10.6 | 10.1(8bar) | 8.7 | ~~~ | 55 |

| 26 | GA75AP | 13.1 | 12.3(8bar) | 11 | 9.7 | 75 |

| 27 | GA75+(A/W)P | 14.7 | 13.8(8bar) | 12.2 | 10.2 | 75 |

| 28 | GA90(A/W)P | 16.2 | 15.6(8bar) | 14.1 | 12 | 90 |

| Table 2 | ||||||

| No | Model | Gas displacement m3/min | Power(kw) | |||

| 7.5bar | 8.5bar | 10bar | 14bar | |||

| 1 | GA90-(W) | 16.8 | 15.8 | 14.4 | 11.1 | 90 |

| 2 | GA110(W) | 20 | 18.8 | 17 | 13.9 | 110 |

| 3 | GA132(W) | 24.1 | 22.9 | 21 | 16.8 | 132 |

| 4 | GA160(W) | 30.4 | 28.9 | 26.8 | 21.7 | 160 |

| No | Model | Gas displacement m3/min | Power(kw) | |||

| 7.5bar | 8.5bar | 10bar | 13bar | |||

| 5 | GA200(W) | 36.1 | 34 | 30.7 | 26.1 | 200 |

| 6 | GA250(W) | 43.7 | 41.7 | 37.8 | 31.7 | 250 |

| 7 | GA315(W) | 55 | 52 | 48 | 315 | |

| 8 | GA355(W) | 60 | 57 | 53 | 46 | 355 |

FAQ

1. What’s Minimum Order Quantity of your air compressor part?

the MOQ is 1pc, need you pay for the delivery cost.

2. What’s kind of your packaging for the air compressor part?

neutral packing or brand pack as your requirement

3. Could I get some samples? How could i pay the sample payment?

yes, we can provide sample, but not free.

payment: paypal, westunion ,TT

4. How long is your Delivery Lead Time ?

If there is stock, the lead time is about 2 WORKING DAYS after we get the payment, if need to be produced, it depens.

5. Could you Calculate the shipping cost for me?

Yes, we are honored to do that for you! Before the freight , please well let us know which seaport or airport near your place.

6. what’s the delivery way?

shipping way: air freight, express, sea

HongKong CZPT Industry Limited

HangZhou City CZPT Compressor Part Co.,Ltd.

Miss Cindy

| Connection: | Female |

|---|---|

| Structure: | Vertical |

| Flexible or Rigid: | Flexible |

| Material: | Plastic |

| Standard: | Standard |

| Function: | Connector |

| Customization: |

Available

| Customized Request |

|---|

Types of Couplings

A coupling is a device that connects two shafts together. It transmits power from one end to another and is used for joining rotating equipment. A coupling is flexible and can accommodate a certain amount of end movement and misalignment. This allows for more flexibility in applications. Various types of couplings are available, and each one serves a specific purpose.

Shaft couplings

There are many types of shaft couplings, and they are used in a wide range of applications. The type you need depends on the torque, speed, and horsepower you need, as well as the size of the shaft and its spatial limitations. You may also need to consider whether the coupling will accommodate misalignment.

Some shaft couplings are flexible, while others are rigid. Flexible couplings can accommodate up to two degrees of misalignment. They are available in different materials, including aluminum, stainless steel, and titanium. They can also be known by different names, depending on the industry. Some couplings can also be used in a single or multiple-shaft application.

The first type of shaft coupling is a rigid coupling, which consists of two parts that fit together tightly around the shafts. These couplings are designed to have more flexibility than sleeved models, and they can be used on fixed shafts as well. The flanged coupling, on the other hand, is designed for heavy loads and is made of two perpendicular flanges. The flanges are large enough to accommodate screws and are generally used with heavy-duty applications.

CZPT shaft couplings are a great choice if you’re looking for a shaft coupling that delivers high performance, durability, and low cost. These metal disc-style couplings provide low backlash and high torsional stiffness. Their high misalignment tolerance reduces reaction loads on connected components, which makes them ideal for high-speed precision applications. Available in single and double-disc models, they have torque ratings of up to 2,200 in-lbs. (250N) and are available in fourteen sizes.

When using shaft couplings, it is important to choose the right type for your application. Backlash can cause a shaft coupling to break or become unusable. In order to prevent this from happening, you should replace worn or loose parts, and ensure that the hub and key are evenly positioned with the shaft. If you’re using a shaft coupling in a motion-control system, it is important to keep the torque level consistent.

Flexible couplings

Flexible couplings are a type of coupling used to connect two shafts. They are made of rubber or plastic and allow for axial movement of the connected equipment. They do not require lubrication and are resistant to fatigue failure. Flexible couplings are useful for a number of applications. A common type of flexible coupling is the gear coupling, which has gear teeth inside its sleeve. Another type of flexible coupling is the metallic membrane coupling. A metallic membrane coupling is flexible due to flexing metallic discs.

One major disadvantage of flexible couplings is their inability to fit certain types of pipe. This is because most couplings need to be stretched to fit the pipe. This problem is often the result of a change in pipe technology. Traditionally, drain and soil pipe is made of ductile iron or cast iron. Today, most pipes are made of PVC, which has a larger outside diameter than either cast or ductile iron. Because of these changes in pipe technology, many coupling manufacturers have not updated their mold sizing.

Flexible couplings can be either metallic, elastomeric, or a combination of the three. While there are some common characteristics of each type, you should always consider the tradeoffs of each type before choosing one. Generally, the most important considerations when selecting a flexible coupling are torque, misalignment, and ease of assembly and maintenance.

Flexible couplings are used in a wide range of industries. They are useful for connecting two pipes to ensure torque transfer. Although the types available are different, these are the most adaptable couplings in the market. They can withstand movement, vibration, and bending without causing any damage to the piping.

Clutch couplings

A clutch coupling connects two rotating shafts by friction. The clutch engages power when the engine is running, disengaging power when the brake is applied. Clutch couplings are used in applications where the speed of a machine is variable or where continuous service is required. The clutch can transmit power, torque, and axial force.

Clutch couplings come in a variety of styles and configurations. Some couplings are flexible, while others are rigid. Flexible couplings are available in a variety of materials, including stainless steel and aluminum. Some couplings also have a non-backlash design, which helps compensate for misalignment.

Clutch couplings may be synchronous or asynchronous. Synchronous couplings engage and disengage automatically when the driven machine exceeds its output speed. These couplings are synchronized by a synchronizing mechanism. When the output speed is exceeded, the synchronizing mechanism initiates the engagement process. The synchronizing mechanism does not engage or disengage when the output speed drops.

High speed clutches are available from a variety of manufacturers. Some manufacturers offer OEM assembly, repair services, and third-party logistics. These manufacturers serve the automotive, chemical, food, and wood industries, as well as the oilfield and material handling industries. Custom clutches can be manufactured for specific applications and can be fitted with additional features, such as precision machined teeth or keyway slots and grooves.

Couplings are available in PCE, C/T, and metric bores. Typically, the size of the input and output shafts will determine which type of coupling is needed. In addition, clutches may be configured for intermediate or high speeds, depending on the required torque.

Clamped couplings

Clamped couplings are commonly used in a variety of industries. They can be used in medical equipment, dental equipment, military equipment, laboratory equipment, and in precision industrial controls. They are available in a wide variety of sizes and keyways. This type of coupling offers a number of advantages, including ease of installation and quick and easy replacement.

A clamp coupling connects two parts by compressing them together. The clamping elements can be formed in a variety of ways, but they all have a gap between their surfaces. This friction squeezes the two parts together, much like pulling two rubber gloves apart. This type of coupling is also useful for joining two hoses or piping units.

Clamped couplings are designed with a single or double clamping shaft. The clamping parts are mounted in two halves and are held together by eight socket head cap screws. They offer high torque capacity and require little installation space. Their high rigidity ensures good positioning accuracy, making them ideal for dynamic drives. In addition, they are wear-free and offer simple radial assembly.

The invention relates to a method and system for clamping pipes to a tank vessel. This invention also relates to a method of loading and unloading tank vessels. The method can be used in oil production platforms and other platforms. A single point mooring method is also used in oil production platforms.

Clamped couplings can also be flexible. They can join two shafts together while allowing a small amount of end movement and misalignment. These couplings may also be used in the assembly of motors and gearboxes.

CZPT’s coupling

CZPT couplings are designed to be flexible, allowing them to accommodate misaligned shafts and transmit torque in either direction. They are made with three discs, two hubs, and a center that are arranged with grooves and fins. These features allow for two degrees of freedom during assembly, and can accommodate misalignment of up to 5% of the shaft diameter.

CZPT couplings have many uses. For example, they can be used to join two parallel coaxial rotating shafts. Their ability to transmit torque at the same rotation mechanism and speed makes them ideal for applications where electrical currents may be a problem. Because the couplings are not made of metal, they are electrically isolated. Designers should test their couplings during the prototype stage to ensure they are working properly.

The CZPT coupling consists of two hubs with one slot on each. An intermediate disk is located between the two hubs. The discs are used to reduce or prevent wear on other machine parts. CZPT couplings are inexpensive and easy to replace. They also have electrical insulation, which makes them easy to repair or replace.

CZPT couplings are a popular choice for stepper motor-driven positioning stages. The plastic center disc offers electrical isolation and absorbs shocks from frequent start/stops. These couplings are available in through-hub and blind-bore styles and can be installed in many applications.

CZPT couplings also allow for small degrees of shaft misalignment. This allows them to function in systems where shaft access is limited. They are easily removed without tools.

editor by CX 2023-07-12

China Stainless Steel Air Quick Release Coupling 304 Such as for Air Compressor coupling base

Merchandise Description

| Brand name Title | Air or Pneumatic Swift Launch Connector Coupling or Coupler |

| Element No. | P001 |

| Substance | Stainless Steel (SUS304) |

| Measurement (inch) | 1/8,1/4,3/8,1/two |

| Shade | Major |

| Surface Remedy | Chrome-plated |

| Emblem | Customized logo or Utilizing our ‘Q’ |

| OEM Accepted | Of course |

| Thread | BSPP, G, NPT |

| Advertising and marketing Type | Common Product |

| Operating Temperature | -twenty-100 |

| Functioning strain | 1.0Mpa |

| Application | Pneumatic equipment,automotive,compressed air,shipbuilding industry,and so forth. |

Item Image:

PACKING AND SHIPPMENT:

WORKSHOP:

Relevant Item:

Ferrule, Hydraulic fittings, Hydraulic hose fittings, Hydraulic adapter, Hydrualic connections, hydraulic 3-piece match, union tee, union cross, and so on

one:Ferrule, matched with many varieties of pipes such as SAE, DIN, EN, GB and many others

2:Metric Fitting

Flat Seal Fitting, Xihu (West Lake) Dis.t-seal fitting, spherical seal fitting, 60° Cone seal fitting, 74° cone seal fitting, 24°cone O-ring L.T. Fitting, 24°cone O-ring H.T. Fitting, JIS 60° Cone Seal Fitting, Standpipe Fitting, Japan Metric Fitting and so forth

3: British Pipe Adapter

JIS BSP 60° Cone seal Adapter, BSPT Adapter, BSP multiseal adapter, BSP flat Seal Adapter, BSP O-ring Seal Adapter

four: Americal Pipe Adaptor

SAE Code 62 Flange, SAE Code sixty one Flange, NPT Adpator, JIC 74°Cone Seal Adaptor, NPSM 60°Cone Seal Adaptor, ORFS Flat Seal Adaptor, SAE O-ring Seal Adaptor

5: Banjo Adaptor

MetricBanjo Adaptor, BSP Banjo Adaptor

six: Staplelok Adaptor

7: Double Ended Adaptor

eight: Metric Changeover Adaptor

nine: British Changeover Adaptor

10:American Changeover Adaptor

FAQ:

Q: How can you guarantee your merchandise high quality?

A: We will organize sample affirmation before production. In the course of the generation, we have specialist QC staffs control the top quality and manufacture in accordance to the verified sample.

Q: Do you offer hydraulic rapid coupling fitting OEM provider and can you create as our drawings?

A: Yes. We provide rapid coupling OEM services and your made drawings.

Q: Do you offer samples ? is it free of charge or further ?

A: Indeed, we could offer you the sample for free charge but do not spend the cost of freight.

Q: What is your terms of payment ?

A: Payment=1000USD, thirty% T/T in advance ,balance just before shippment.

Q: What’s your delivery time?

A: Generally, we will arrange cargo with twenty days following obtaining the deposit. If urgent, we can also meet up with your requirement.

| Customized: | Customized |

|---|---|

| Number of Cylinders: | Universal |

| Type: | Quick Connector |

| Usage: | Air Compressor, Air Line |

| Brand: | Xinliyuan |

| Work Temperature: | -20-100 |

###

| Samples: |

US$ 0.01/Piece

1 Piece(Min.Order) |

|---|

###

| Customization: |

Available

|

|---|

###

| Brand Name | Air or Pneumatic Quick Release Connector Coupling or Coupler |

| Part No. | P001 |

| Material | Stainless Steel (SUS304) |

| Size (inch) | 1/8,1/4,3/8,1/2 |

| Color | Primary |

| Surface Treatment | Chrome-plated |

| Logo | Customized logo or USing our ‘Q’ |

| OEM Accepted | Yes |

| Thread | BSPP, G, NPT |

| Marketing Type | Ordinary Product |

| Operating Temperature | -20-100 |

| Working pressure | 1.0Mpa |

| Application | Pneumatic tools,automotive,compressed air,shipbuilding industry,etc. |

| Customized: | Customized |

|---|---|

| Number of Cylinders: | Universal |

| Type: | Quick Connector |

| Usage: | Air Compressor, Air Line |

| Brand: | Xinliyuan |

| Work Temperature: | -20-100 |

###

| Samples: |

US$ 0.01/Piece

1 Piece(Min.Order) |

|---|

###

| Customization: |

Available

|

|---|

###

| Brand Name | Air or Pneumatic Quick Release Connector Coupling or Coupler |

| Part No. | P001 |

| Material | Stainless Steel (SUS304) |

| Size (inch) | 1/8,1/4,3/8,1/2 |

| Color | Primary |

| Surface Treatment | Chrome-plated |

| Logo | Customized logo or USing our ‘Q’ |

| OEM Accepted | Yes |

| Thread | BSPP, G, NPT |

| Marketing Type | Ordinary Product |

| Operating Temperature | -20-100 |

| Working pressure | 1.0Mpa |

| Application | Pneumatic tools,automotive,compressed air,shipbuilding industry,etc. |

Programming With Couplings

A coupling is a mechanical device that connects two shafts together and transmits power. Its purpose is to join rotating equipment and allows some degree of end-movement or misalignment. There are many different types of couplings. It’s important to choose the right one for your application.

Mechanical connection between two shafts

There are many ways to achieve mechanical connection between two shafts, including the use of a coupling. One common type is the beam coupling, which is also known as a helical coupling. It is used for transmission of torque between two shafts. This type of connection accommodates axial, parallel and angular misalignments.

The hubs and shafts of a worm gear are connected together by a coupling. This mechanical connection allows one shaft to turn another without causing a mechanical failure. This type of coupling is made from sliding or rubbing parts to transfer torque. However, the coupling is not designed to withstand jerks, so it isn’t suitable for high-speed applications.

The use of a coupling is common in machinery and equipment. It helps transmit power from one drive shaft to the other, while adding mechanical flexibility. It is also useful for reducing the impact and vibration caused by misalignment. It also protects the drive shaft components from wear and tear.

A double-hook coupling can be used to provide a uniform angular velocity at the driven shaft. Another example is a double-jointed coupling. A double-jointed coupling can be used to connect shafts that are not directly intersecting. The double-jointed yoke can be used for the same purpose.

A shaft coupling is a device that maintains a strong mechanical connection between two shafts. It transfers motion from one shaft to another, at all loads and misalignments. Unlike a conventional linkage, a shaft coupling isn’t designed to allow relative motion between the two shafts. Couplings often serve several purposes in a machine, but their primary use is torque and power transmission.

Functions that control the flow of another function

One of the simplest programming constructs is a function that controls the flow of another function. A function can take an argument and return a different value, but it must be ready to return before it can pass that value to another function. To do this, you can use the goto statement and the if statement. Another way to control flow is to use a conditional statement.

Criteria for selecting a coupling

There are several important factors to consider when choosing the right coupling. One of the most important factors is coupling stiffness, which depends on the material used and the shape. The stiffness of a coupling determines its ability to resist elastic deformation. A stiff coupling is desirable for certain types of applications, but it’s undesirable for others. Stiffness can reduce the performance of a system if there’s too much inertia. To avoid this, ensure that the coupling you choose is within the recommended limits.

The size of a coupling is also important. Different coupling types can accommodate different shaft sizes and shapes. Some couplings have special features, such as braking and shear pin protection. When choosing a coupling, you should also consider the type of driven equipment. If you need to connect a high-torque motor, for example, you’ll want to choose a gear coupling. Likewise, a high-speed machine may require a disc coupling.

Another factor to consider when selecting a coupling is the torque rating. Despite its importance, it’s often underestimated. The torque rating is defined as the torque of the coupling divided by its OD. In some cases, torque may fluctuate during a cycle, requiring a coupling with a higher torque rating.

Torsionally flexible couplings are also important to consider. Their design should be able to withstand the torque required during operation, as well as the required speed. The coupling should also have a high degree of torsional stiffness, as well as damping. Furthermore, a damping coupling can reduce the energy wasted through vibration.