Product Description

Factory Sale high quality elastic single double diaphragm flexible shaft coupling

Description:

JM series diaphragm flexible coupling is widely used in the machinery and equipment industry, metallurgy, mines, petroleum, chemical, electric power, shipbuilding, lifting transport, textile, light industry, agricultural machinery, printing machinery, and water pump, fan, etc. in the transmission of power machine.

Main characteristics:

1. Compensation two-axis misalignment of the ability, and tooth type coupling can be much more than a double angle displacement, radial displacement of the small, flexible, allowing a certain axial, radial, and angular displacement.

2. Obvious damping effect, no noise, no wear, and tear.

3. High transmission efficiency, up to 99.86%. Especially suitable for medium and high-speed high-power transmission.

4. Adapt to high temperature (-80+300) and harsh environments, and can be in shock, vibration, safety, and dynamic conditions.

5. Simple structure, lightweight, small size, convenient assembly, and disassembly. Without moving the machine can be disassembled (with intermediate type), with no need for lubrication.

6. Accurately convey the rotational speed, the operation has not turned bad, can be used for the transmission of precision machinery.

Paramaters:

Applicable Industries:

Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Advertising Company.

Packing & Shipping:

FAQ:

Q 1: Are you a trading company or a manufacturer?

A: We are a professional manufacturer specializing in manufacturing

various series of couplings.

Q 2:Can you do OEM?

Yes, we can. We can do OEM & ODM for all the customers with customized artworks in PDF or AI format.

Q 3:How long is your delivery time?

Generally, it is 20-30 days if the goods are not in stock. It is according to quantity.

Q 4: How long is your warranty?

A: Our Warranty is 12 months under normal circumstances.

Q 5: Do you have inspection procedures for coupling?

A:100% self-inspection before packing.

Q 6: Can I have a visit to your factory before the order?

A: Sure, welcome to visit our factory. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Maintenance Requirements for Optimal Performance of Elastic Couplings

Maintaining elastic couplings is essential to ensure their optimal performance and longevity. Following these maintenance guidelines can help prevent premature wear and failure:

- Regular Inspection: Periodically inspect the coupling for signs of wear, such as cracks, deformities, or visible damage. This can help identify issues early and prevent further damage.

- Lubrication: Some elastic couplings require lubrication to reduce friction and wear. Follow the manufacturer’s recommendations for lubrication intervals and use compatible lubricants.

- Torque Check: Check the coupling’s torque values to ensure they are within the specified range. This helps maintain proper torque transmission and prevents overloading.

- Alignment Check: Monitor the alignment of the connected shafts regularly. Misalignment can cause excessive stress on the coupling, leading to premature failure.

- Vibration Analysis: Perform vibration analysis to identify any abnormal vibrations in the system. Excessive vibrations could indicate coupling or system issues that need attention.

- Temperature and Environment: Ensure that the coupling operates within the recommended temperature and environmental limits. Extreme conditions can affect the coupling’s material properties and performance.

- Coupling Wear: Keep track of the coupling’s wear over time. Depending on the application, the coupling might need replacement after a certain period of service.

- Expert Inspection: If any unusual symptoms or problems arise, consider having the coupling inspected by a qualified technician or engineer to diagnose the issue accurately.

Adhering to these maintenance practices helps extend the service life of elastic couplings, ensures reliable performance, and minimizes unexpected downtime and costly repairs.

Impact of Temperature Variations on Elastic Coupling Performance

Elastic couplings can be sensitive to temperature variations, and their performance can be influenced by both high and low temperatures:

1. High Temperatures: Elevated temperatures can cause the elastomeric material used in elastic couplings to soften, leading to a decrease in its mechanical properties. This can result in reduced torsional stiffness, damping capabilities, and overall coupling performance. High temperatures can also accelerate the aging process of the elastomer, leading to a shorter lifespan of the coupling. Additionally, excessive heat can cause thermal expansion of the coupling’s components, potentially leading to misalignment issues.

2. Low Temperatures: Extremely low temperatures can cause the elastomeric material to become more rigid, reducing its flexibility and damping characteristics. This can result in increased transmission of vibrations and shocks between connected components. Cold temperatures can also make the elastomer more brittle, increasing the risk of cracking or rupturing under mechanical stress.

It’s important to select an elastic coupling material that is suitable for the anticipated temperature range of the application. Some elastomers are formulated to perform well across a wide temperature range, while others are better suited for specific temperature conditions. Regular maintenance and inspection of elastic couplings in extreme temperature environments are crucial to ensure that the coupling continues to function as intended.

Principles of Torsionally Elastic Couplings

Torsionally elastic couplings, also known as flexible couplings, operate based on the principles of flexibility and torsional elasticity. These couplings are designed to transmit torque while accommodating misalignments, dampening vibrations, and providing protection against shock loads. Here’s how they work:

- Flexibility: Torsionally elastic couplings are made of materials that can flex or bend to some degree. This flexibility allows them to absorb misalignments between connected shafts, such as angular, parallel, and axial misalignments.

- Torsional Elasticity: The material properties of the coupling allow it to twist or deform slightly under torque loads. When torque is applied to one end of the coupling, the coupling flexes and twists to transmit torque to the other end while compensating for any misalignments.

- Vibration Dampening: The torsional elasticity of the coupling helps dampen vibrations that occur due to sudden torque changes or variations in load. This is especially important in applications where smooth operation and reduced vibrations are essential.

- Shock Load Protection: Torsionally elastic couplings can absorb and mitigate shock loads that might occur during sudden starts, stops, or changes in load. This protection prevents damage to connected equipment and extends the lifespan of machinery.

Overall, torsionally elastic couplings enhance the performance, reliability, and durability of machinery by providing flexibility, dampening vibrations, and protecting against misalignments and shock loads.

editor by CX 2024-05-14

China factory Pump Fan Compressor Single Joint Gas Turbines Key-Joint Double Elastic Disc Flexible Shaft Lock Disc Single Diaphragm Coupling for Truck

Product Description

Pump Fan Compressor Single Joint Gas Turbines Key-Joint Double Elastic Disc Flexible Shaft Lock Disc Single Diaphragm Coupling for Truck

Metal flex couplings are disc type couplings in which several flexible metallic elements are alternately attached with bolts to opposite flanges. As polymeric elastomer is replaced by metal disc, Metal Flex coupling provides excellent temperature capability without sacrificing angular and axial misalignment. The coupling provides low axial and bending stiffness while possessing high torsional rigidity. The stretched shim pack design of CHINAMFG Metal Flex couplings provides zero backlash. CHINAMFG Metal Flex couplings are available up to 13367 Nm torque with single shim pack (UMK) and double shim pack (UMS) series.

FEATURES

1.Power to weight ratio high

2.Accommodates angular and axial misalignments

3.High temperature application

4.Visual inspection is possible without dismantling equipments

5.Low axial stiffness with high torsional rigidity

6.High-speed capacity

7.Range up to 12000 Nm

8.Added advantage of stretch fitted shim pack

|

Material Available |

Stainless Steel:SS201,SS301, SS303, SS304, SS316, SS416 etc. |

|

CNC Turning |

φ0.5 – φ300 * 750 mm,+/-0.005 mm |

|

CNC Milling |

510 * 1571 * 500 mm(max),+/-0.001 mm-+/-0.005 mm |

|

Surface Finish |

Aluminum:Clear Anodized,Color Anodized,Sandblast Anodized,Chemical Film,Brushing,Polishing,Chroming. |

|

Drawing Format |

IGS,STP,X_T ,DXF,DWG , Pro/E, PDF |

|

Test Equipment |

Measurement instrument, Projector, CMM, Altimeter, Micrometer, Thread Gages, Calipers, Pin Gauge etc. |

Production workshop:

Manufacturer of Couplings, Fluid Coupling, JAW Coupling, can interchange and replacement of lovejoy coupling and so on.

A coupling can interchange and replacement of lovejoy coupling is a device used to connect 2 shafts together at their ends for the purpose of transmitting power. The primary purpose of couplings is to join 2 pieces of rotating equipment while permitting some degree of misalignment or end movement or both. In a more general context, a coupling can also be a mechanical device that serves to connect the ends of adjacent parts or objects. Couplings do not normally allow disconnection of shafts during operation, however there are torque limiting couplings which can slip or disconnect when some torque limit is exceeded. Selection, installation and maintenance of couplings can lead to reduced maintenance time and maintenance cost.

Company information:

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Compensation for Misalignment in Elastic Couplings

Elastic couplings are designed to accommodate certain degrees of misalignment between connected components in mechanical systems. The elastomeric material used in the coupling plays a crucial role in this compensation process:

When the two components connected by the elastic coupling experience angular, parallel, or axial misalignment, the elastomeric material deforms to a certain extent. This deformation allows the coupling to maintain its connection while absorbing the misalignment-induced stresses and forces.

The elastomer acts as a flexible link between the components, allowing them to move relative to each other within specified limits. The deformation of the elastomer also helps distribute the load more evenly, reducing stress concentrations and the risk of premature wear or damage to the coupling or connected components.

Elastic couplings can compensate for both static and dynamic misalignment, making them suitable for applications where minor misalignment is unavoidable due to factors such as manufacturing tolerances, thermal expansion, or vibration.

It’s important to note that while elastic couplings can accommodate misalignment, excessive misalignment should still be avoided, as it can lead to accelerated wear and reduced coupling lifespan. Regular inspection and maintenance are recommended to ensure that the coupling is operating within its designed limits.

Advancements in Elastic Coupling Technology

Recent advancements in elastic coupling technology have led to improved performance and capabilities. Some notable developments include:

- Enhanced Materials: The use of advanced materials, such as high-performance elastomers and composites, has resulted in elastic couplings that offer higher strength, durability, and resistance to wear and fatigue.

- Optimized Designs: Engineers are employing advanced computer simulations and modeling techniques to optimize the design of elastic couplings. This has led to designs that provide better torsional flexibility, reduced backlash, and improved performance in demanding conditions.

- Vibration Dampening: Advancements in elastic coupling technology have focused on improving vibration dampening properties. This is particularly important in applications where minimizing vibration and shock is crucial for the machinery’s precision and longevity.

- Customization: Modern elastic coupling manufacturers offer more options for customization, allowing engineers to select the best coupling configuration, size, and material for their specific application requirements.

- Smart Couplings: Some elastic couplings now incorporate sensors and monitoring technology to provide real-time data on coupling performance, misalignment, and wear. This data can aid in predictive maintenance and enhance overall system reliability.

These advancements in elastic coupling technology continue to contribute to the efficiency, reliability, and overall performance of machinery systems in various industries.

Principles of Torsionally Elastic Couplings

Torsionally elastic couplings, also known as flexible couplings, operate based on the principles of flexibility and torsional elasticity. These couplings are designed to transmit torque while accommodating misalignments, dampening vibrations, and providing protection against shock loads. Here’s how they work:

- Flexibility: Torsionally elastic couplings are made of materials that can flex or bend to some degree. This flexibility allows them to absorb misalignments between connected shafts, such as angular, parallel, and axial misalignments.

- Torsional Elasticity: The material properties of the coupling allow it to twist or deform slightly under torque loads. When torque is applied to one end of the coupling, the coupling flexes and twists to transmit torque to the other end while compensating for any misalignments.

- Vibration Dampening: The torsional elasticity of the coupling helps dampen vibrations that occur due to sudden torque changes or variations in load. This is especially important in applications where smooth operation and reduced vibrations are essential.

- Shock Load Protection: Torsionally elastic couplings can absorb and mitigate shock loads that might occur during sudden starts, stops, or changes in load. This protection prevents damage to connected equipment and extends the lifespan of machinery.

Overall, torsionally elastic couplings enhance the performance, reliability, and durability of machinery by providing flexibility, dampening vibrations, and protecting against misalignments and shock loads.

editor by CX 2024-05-02

China manufacturer Customized Jt 140 Diaphragm Type Elastic Coupling, Flexible Diaphragm Shaft Coupling

Product Description

Customized JT 140 Diaphragm Type Elastic Coupling ,Flexible Diaphragm Shaft Coupling,Single Diaphragm Coupling

| Product Name | Densen customized JT 140 Diaphragm Type Elastic Coupling ,Flexible Diaphragm Shaft Coupling,Single Diaphragm Coupling |

| DN mm | 90~560mm |

| Rated Torque | 320~170000 N·m |

| Max Allowalbe Speed | 12700~2000RPM |

| Material | 45# Steel+Stainless steel(Diaphragm) |

| Application | Widely used in metallurgy, mining, engineering and other fields. |

Why Choose Us

1. One stop service:

We have 5 own factories and 50+ sub-contractors located in different areas of China to offer you one-stop manufacturing and purchasing services to help you save time and reduce procurement cost.

2. Your eyes in China:

Our commitment to quality permeates from quoting, scheduling, production, inspection to deliver into your warehouse, our QC team will remark the errors if has on QC documents for your checking before delivery as your 3rd party.

3. Your R&Dconsultant:

With professional engineers team and 29 years manufacture experience ,we would help you work out problems during new parts’ development, optimize design and recommend the most cost-effective solution.

4. Your Emergency Solver:

With continued grown factories team and our QC teams located in different areas, if customers need to expedite the delivery, we would be able to adopt another factory to produce together immediately.

5. Quality Guaranty:

No matter how long time the products delivered, we are responsible for the quality. In case the products be rejected, we would replace them or return fund according to your demand without hesitation

FAQQ1. Are you a manufacturer or a trader?

Manufacture, we have 5 own foundries, 4 in ZheJiang Province, 1 in ZHangZhoug Province

Q2. Do you have MOQ request?

1 pcs per order is ok with us , unless material is seldom used.

Q3. If I only have a sample,without drawings, can you quote then manufacture for me?

Just send us the sample, we would have the sample simulated and measured by professional equipment then issue formal drawings for

you , at the same time, we could help you optimize the design according to your demand and related processes’ feasibility.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Limitations and Disadvantages of Elastic Couplings

While elastic couplings offer various benefits, they also come with certain limitations and disadvantages that engineers and designers need to consider:

- Torsional Stiffness: Elastic couplings provide flexibility, but this can lead to lower torsional stiffness compared to rigid couplings. In applications requiring high torsional stiffness, elastic couplings might not be the ideal choice.

- Energy Loss: Due to the elastic nature of the material, a portion of the transmitted torque can be absorbed as deformation energy in the elastomer. This can result in energy losses and reduce overall efficiency.

- Wear and Fatigue: The elastomer element in elastic couplings can experience wear, fatigue, and deterioration over time, especially in applications with high loads or extreme operating conditions. Regular maintenance and monitoring are essential to ensure proper functionality.

- Temperature Sensitivity: Some elastomer materials used in elastic couplings might be sensitive to temperature fluctuations. Extreme temperatures can affect the properties of the elastomer and compromise the coupling’s performance.

- Alignment Requirements: While elastic couplings can accommodate minor misalignments, excessive misalignment can still lead to premature wear and reduced coupling lifespan. Proper alignment remains important for optimal performance.

Engineers and designers must carefully assess the specific requirements of their applications to determine if the advantages of elastic couplings outweigh the potential limitations and disadvantages.

Impact of Temperature Variations on Elastic Coupling Performance

Elastic couplings can be sensitive to temperature variations, and their performance can be influenced by both high and low temperatures:

1. High Temperatures: Elevated temperatures can cause the elastomeric material used in elastic couplings to soften, leading to a decrease in its mechanical properties. This can result in reduced torsional stiffness, damping capabilities, and overall coupling performance. High temperatures can also accelerate the aging process of the elastomer, leading to a shorter lifespan of the coupling. Additionally, excessive heat can cause thermal expansion of the coupling’s components, potentially leading to misalignment issues.

2. Low Temperatures: Extremely low temperatures can cause the elastomeric material to become more rigid, reducing its flexibility and damping characteristics. This can result in increased transmission of vibrations and shocks between connected components. Cold temperatures can also make the elastomer more brittle, increasing the risk of cracking or rupturing under mechanical stress.

It’s important to select an elastic coupling material that is suitable for the anticipated temperature range of the application. Some elastomers are formulated to perform well across a wide temperature range, while others are better suited for specific temperature conditions. Regular maintenance and inspection of elastic couplings in extreme temperature environments are crucial to ensure that the coupling continues to function as intended.

Principles of Torsionally Elastic Couplings

Torsionally elastic couplings, also known as flexible couplings, operate based on the principles of flexibility and torsional elasticity. These couplings are designed to transmit torque while accommodating misalignments, dampening vibrations, and providing protection against shock loads. Here’s how they work:

- Flexibility: Torsionally elastic couplings are made of materials that can flex or bend to some degree. This flexibility allows them to absorb misalignments between connected shafts, such as angular, parallel, and axial misalignments.

- Torsional Elasticity: The material properties of the coupling allow it to twist or deform slightly under torque loads. When torque is applied to one end of the coupling, the coupling flexes and twists to transmit torque to the other end while compensating for any misalignments.

- Vibration Dampening: The torsional elasticity of the coupling helps dampen vibrations that occur due to sudden torque changes or variations in load. This is especially important in applications where smooth operation and reduced vibrations are essential.

- Shock Load Protection: Torsionally elastic couplings can absorb and mitigate shock loads that might occur during sudden starts, stops, or changes in load. This protection prevents damage to connected equipment and extends the lifespan of machinery.

Overall, torsionally elastic couplings enhance the performance, reliability, and durability of machinery by providing flexibility, dampening vibrations, and protecting against misalignments and shock loads.

editor by CX 2024-04-19

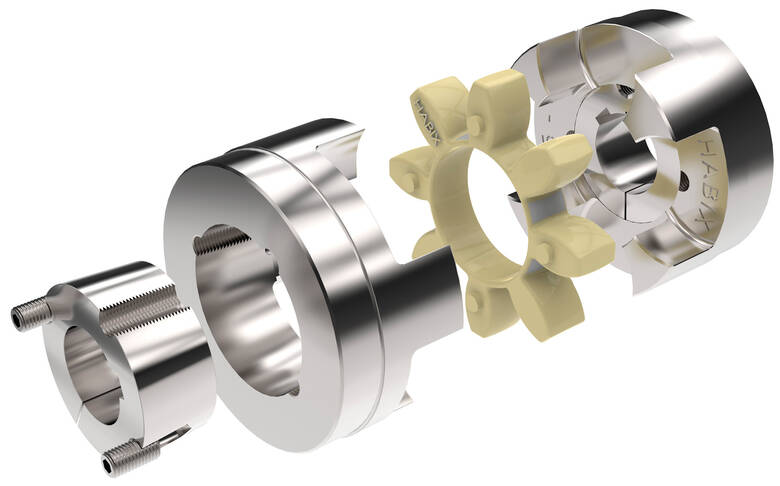

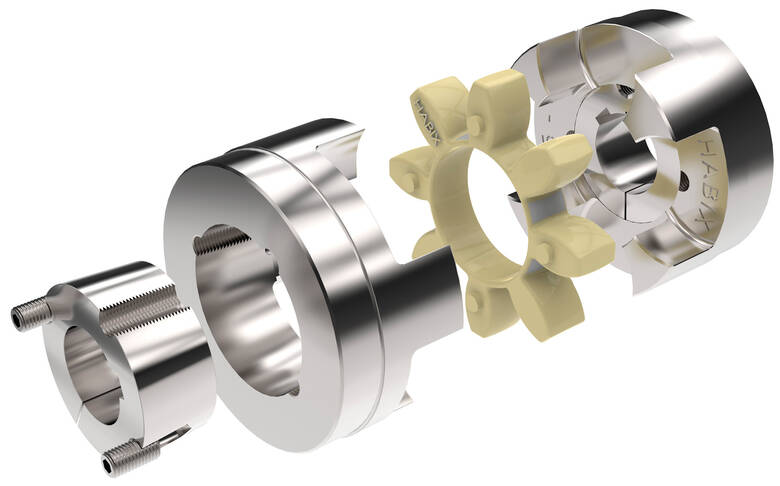

China manufacturer Type Double Elastic Diaphragm Coupling with Locking Assemblies Taper Bush for Servo Motor Custom Coupling

Product Description

Product Description

The maximum opening value is a circular hole or a tapered hole with a keyway.

Main applications:

DWZ disc eddy current brake is mainly used as load in loading dynamometer equipment. it is experimental apparatus which can measure the dynamic mechanical properties, especially in dynamic loading test whose power value is small or tiny, also can be treated as suction power devices of other dynamic devices.

DW series disc eddy current dynamometer is, is that add device for measuring torque and rotational speed on DWZ series disc eddy current brake, it is experimental apparatus which can measure the dynamic mechnical properties, especial in dynamic loading test whose power value is small or tiny.

CW eddy current brake as a load is mainly used to measure the mechanical characteristics of inspection equipment, it and other control instrument (including loading apparatus, torque speed sensor and torque power acquisition instrument etc.) can be composed of eddy current dynamometer can be used for performance testing of the internal combustion engine, motor, gas turbine, automobile and its dynamic mechanical components, compared with other power measuring device, the CW series power measuring device has the advantages of reliability, high stability and practicability.

| Eddy current brake/dynamometer | Rated Power | Rated torque | Rated speed | Maximum rotational speed | Turning inertia | Maximum excitation voltage | Maximum excitation Current | Cooling water pressure | Flow of the cooling water |

| DWZ/DW-0.75 | 0.75 | 5 | 2000-2600 | 16000 | 0.002 | 80 | 3 | 0.1~0.3 | 1 |

| DWZ/DW-3 | 3 | 10 | 2000-2600 | 14000 | 0.003 | 80 | 3 | 0.1~0.3 | 2 |

| DWZ/DW-6 | 6 | 25 | 2000-2600 | 14000 | 0.003 | 80 | 3 | 0.1~0.3 | 3 |

| DWZ/DW-10 | 10 | 50 | 2000-2600 | 13000 | 0.01 | 80 | 3 | 0.1~0.3 | 4.5 |

| DWZ/DW-16 | 16 | 70 | 2000-2600 | 13000 | 0.02 | 80 | 3.5 | 0.1~0.3 | 6.5 |

| DWZ/DW-25 | 25 | 120 | 2000-2600 | 11000 | 0.05 | 80 | 3.5 | 0.1~0.3 | 15 |

| DWZ/DW-40 | 40 | 160 | 2000-2600 | 10000 | 0.1 | 90 | 4 | 0.1~0.3 | 25 |

| DWZ/DW-63 | 63 | 250 | 2000-2600 | 9000 | 0.18 | 90 | 4 | 0.1~0.3 | 45 |

| DWZ/DW-100 | 100 | 400 | 2000-2600 | 8500 | 0.32 | 120 | 4 | 0.1~0.3 | 60 |

| DWZ/DW-160 | 160 | 600 | 2000-2600 | 8000 | 0.52 | 120 | 5 | 0.1~0.3 | 100 |

| DWZ/DW-250 | 250 | 1100 | 2000-2600 | 7000 | 1.8 | 150 | 5 | 0.2~0.4 | 180 |

| DWZ/DW-300 | 300 | 1600 | 2000-2600 | 6000 | 2.7 | 150 | 5 | 0.2~0.4 | 210 |

| DWZ/DW-400 | 400 | 2200 | 2000-2600 | 5000 | 3.6 | 180 | 10 | 0.2~0.4 | 300 |

| DWZ/DW-630 | 630 | 3600 | 2000-2600 | 5000 | 5.3 | 180 | 10 | 0.2~0.4 | 450 |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Real-World Applications of Elastic Couplings

Elastic couplings find extensive use in various industries and applications where the reduction of vibration and shock is critical for performance, efficiency, and equipment longevity. Here are some examples:

- Industrial Machinery: Elastic couplings are commonly employed in industrial machinery such as pumps, compressors, conveyors, and generators. They help minimize vibration and shock, ensuring smooth and reliable operation while protecting sensitive components.

- Automotive Industry: In automotive applications, elastic couplings are used in drivetrains to dampen vibrations and shocks between the engine and the transmission. This enhances driving comfort, reduces noise, and prevents excessive wear on connected components.

- Power Generation: Power generation equipment, including turbines and generators, benefits from elastic couplings that absorb torsional vibrations and shocks. This aids in maintaining stable power output and extending the lifespan of critical components.

- Printing and Packaging: Printing presses and packaging machinery rely on elastic couplings to reduce vibrations during high-speed operations. This ensures precise printing and packaging while preventing damage to sensitive components.

- Robotics and Automation: Elastic couplings are crucial in robotics and automation systems to mitigate vibrations and shocks that can affect accuracy and reliability. They enable precise movement control and consistent performance.

- Medical Equipment: Medical devices such as MRI machines and X-ray equipment utilize elastic couplings to minimize vibrations that could impact image quality and precision during medical procedures.

These examples highlight how elastic couplings contribute to optimal performance, reduced maintenance, and increased equipment lifespan across diverse industries.

Maintaining the Longevity of Elastic Couplings

Ensuring the longevity and optimal performance of elastic couplings requires proper maintenance and care. Here are some key considerations:

- Regular Inspection: Periodically inspect the coupling for signs of wear, damage, or misalignment. Look for cracks, tears, or other deformations in the elastic elements.

- Lubrication: Some elastic couplings require lubrication for smooth operation. Follow the manufacturer’s guidelines on lubrication intervals and recommended lubricants.

- Environmental Conditions: Consider the operating environment of the coupling. Extreme temperatures, chemicals, moisture, and other factors can affect the coupling’s lifespan. Choose materials and designs suitable for the specific conditions.

- Proper Alignment: Ensure that the connected components are properly aligned to minimize excessive stress on the coupling. Misalignment can accelerate wear and reduce performance.

- Load Capacity: Do not exceed the coupling’s recommended torque and load ratings. Overloading the coupling can lead to premature failure.

- Shock and Vibration: If the system experiences frequent shock or vibration, consider using dampening or vibration-absorbing components to reduce the stress on the coupling.

- Replacement: When signs of wear or damage become noticeable, promptly replace the coupling to avoid further issues. Delaying replacement can lead to more significant problems in the machinery system.

- Follow Manufacturer Guidelines: Always follow the manufacturer’s recommendations for installation, operation, and maintenance of the specific coupling model.

By adhering to these considerations and performing regular maintenance tasks, engineers can extend the lifespan of elastic couplings and ensure reliable and efficient operation in various machinery applications.

Principles of Torsionally Elastic Couplings

Torsionally elastic couplings, also known as flexible couplings, operate based on the principles of flexibility and torsional elasticity. These couplings are designed to transmit torque while accommodating misalignments, dampening vibrations, and providing protection against shock loads. Here’s how they work:

- Flexibility: Torsionally elastic couplings are made of materials that can flex or bend to some degree. This flexibility allows them to absorb misalignments between connected shafts, such as angular, parallel, and axial misalignments.

- Torsional Elasticity: The material properties of the coupling allow it to twist or deform slightly under torque loads. When torque is applied to one end of the coupling, the coupling flexes and twists to transmit torque to the other end while compensating for any misalignments.

- Vibration Dampening: The torsional elasticity of the coupling helps dampen vibrations that occur due to sudden torque changes or variations in load. This is especially important in applications where smooth operation and reduced vibrations are essential.

- Shock Load Protection: Torsionally elastic couplings can absorb and mitigate shock loads that might occur during sudden starts, stops, or changes in load. This protection prevents damage to connected equipment and extends the lifespan of machinery.

Overall, torsionally elastic couplings enhance the performance, reliability, and durability of machinery by providing flexibility, dampening vibrations, and protecting against misalignments and shock loads.

editor by CX 2024-04-17

China Standard Pump Fan Compressor Single Joint Gas Turbines Key-Joint Double Elastic Disc Flexible Shaft Lock Disc Single Diaphragm Coupling for Truck

Product Description

Pump Fan Compressor Single Joint Gas Turbines Key-Joint Double Elastic Disc Flexible Shaft Lock Disc Single Diaphragm Coupling for Truck

Metal flex couplings are disc type couplings in which several flexible metallic elements are alternately attached with bolts to opposite flanges. As polymeric elastomer is replaced by metal disc, Metal Flex coupling provides excellent temperature capability without sacrificing angular and axial misalignment. The coupling provides low axial and bending stiffness while possessing high torsional rigidity. The stretched shim pack design of CHINAMFG Metal Flex couplings provides zero backlash. CHINAMFG Metal Flex couplings are available up to 13367 Nm torque with single shim pack (UMK) and double shim pack (UMS) series.

FEATURES

1.Power to weight ratio high

2.Accommodates angular and axial misalignments

3.High temperature application

4.Visual inspection is possible without dismantling equipments

5.Low axial stiffness with high torsional rigidity

6.High-speed capacity

7.Range up to 12000 Nm

8.Added advantage of stretch fitted shim pack

|

Material Available |

Stainless Steel:SS201,SS301, SS303, SS304, SS316, SS416 etc. |

|

CNC Turning |

φ0.5 – φ300 * 750 mm,+/-0.005 mm |

|

CNC Milling |

510 * 1571 * 500 mm(max),+/-0.001 mm-+/-0.005 mm |

|

Surface Finish |

Aluminum:Clear Anodized,Color Anodized,Sandblast Anodized,Chemical Film,Brushing,Polishing,Chroming. |

|

Drawing Format |

IGS,STP,X_T ,DXF,DWG , Pro/E, PDF |

|

Test Equipment |

Measurement instrument, Projector, CMM, Altimeter, Micrometer, Thread Gages, Calipers, Pin Gauge etc. |

Production workshop:

Manufacturer of Couplings, Fluid Coupling, JAW Coupling, can interchange and replacement of lovejoy coupling and so on.

A coupling can interchange and replacement of lovejoy coupling is a device used to connect 2 shafts together at their ends for the purpose of transmitting power. The primary purpose of couplings is to join 2 pieces of rotating equipment while permitting some degree of misalignment or end movement or both. In a more general context, a coupling can also be a mechanical device that serves to connect the ends of adjacent parts or objects. Couplings do not normally allow disconnection of shafts during operation, however there are torque limiting couplings which can slip or disconnect when some torque limit is exceeded. Selection, installation and maintenance of couplings can lead to reduced maintenance time and maintenance cost.

Company information:

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Maintenance Requirements for Optimal Performance of Elastic Couplings

Maintaining elastic couplings is essential to ensure their optimal performance and longevity. Following these maintenance guidelines can help prevent premature wear and failure:

- Regular Inspection: Periodically inspect the coupling for signs of wear, such as cracks, deformities, or visible damage. This can help identify issues early and prevent further damage.

- Lubrication: Some elastic couplings require lubrication to reduce friction and wear. Follow the manufacturer’s recommendations for lubrication intervals and use compatible lubricants.

- Torque Check: Check the coupling’s torque values to ensure they are within the specified range. This helps maintain proper torque transmission and prevents overloading.

- Alignment Check: Monitor the alignment of the connected shafts regularly. Misalignment can cause excessive stress on the coupling, leading to premature failure.

- Vibration Analysis: Perform vibration analysis to identify any abnormal vibrations in the system. Excessive vibrations could indicate coupling or system issues that need attention.

- Temperature and Environment: Ensure that the coupling operates within the recommended temperature and environmental limits. Extreme conditions can affect the coupling’s material properties and performance.

- Coupling Wear: Keep track of the coupling’s wear over time. Depending on the application, the coupling might need replacement after a certain period of service.

- Expert Inspection: If any unusual symptoms or problems arise, consider having the coupling inspected by a qualified technician or engineer to diagnose the issue accurately.

Adhering to these maintenance practices helps extend the service life of elastic couplings, ensures reliable performance, and minimizes unexpected downtime and costly repairs.

Backlash in Elastic Couplings

Backlash refers to the amount of play or clearance between mating components in a mechanical system, particularly in elastic couplings. In an elastic coupling, backlash is the angular movement or rotation that occurs when there is a change in direction of the input shaft without an immediate response from the output shaft.

Backlash is a result of the elasticity and flexibility of the coupling’s components, such as the elastomer or other flexible elements. When the input direction changes, the elastic elements need to overcome their deformation before transmitting torque to the output shaft. This delay can lead to a temporary loss of motion and reduced precision in positioning applications.

Backlash can have a negative impact on the accuracy, repeatability, and overall performance of a machinery system. It can result in positioning errors, reduced responsiveness, and even potential damage to the system. Therefore, minimizing backlash is crucial in applications that require high precision and responsiveness.

Engineers can address backlash in elastic couplings by selecting couplings with lower compliance, optimizing the design to minimize the flexibility of the coupling elements, and using additional components like anti-backlash devices or preloaded mechanisms.

Industries Using Elastic Couplings

Elastic couplings find extensive use in various industries due to their unique benefits:

- Industrial Manufacturing: Elastic couplings are widely used in manufacturing equipment, conveyors, and assembly lines to maintain smooth operation and reduce vibrations.

- Automotive: Automotive applications include engine components, powertrain systems, and vehicle suspension systems where flexibility and vibration dampening are crucial.

- Power Generation: Elastic couplings are used in power generation equipment such as generators, turbines, and pumps to absorb torsional vibrations and enhance efficiency.

- Aerospace: In aerospace applications, elastic couplings help dampen vibrations in critical components like aircraft engines and control systems.

- Renewable Energy: Wind turbines and solar tracking systems benefit from elastic couplings to accommodate misalignments and vibrations caused by changing wind conditions.

- Mining: Mining equipment such as crushers, conveyors, and screens utilize elastic couplings to handle varying loads and minimize shock loads.

- Marine: Elastic couplings are used in marine propulsion systems and ship equipment to manage torque fluctuations and reduce vibrations.

These industries rely on elastic couplings to enhance performance, extend machinery lifespan, and minimize downtime due to vibrations, misalignments, and shock loads.

editor by CX 2024-04-11

China best Hot Sale MP Series Elastic Diaphragm Coupling with Low Price

Product Description

| Company Profile: |

Up Gold(ZheJiang )Automation Technology Co. Ltd, is a supplier of linear guide way, linear rail series,lead screw,block bearing, roller bearing ,ball bearing,pillow block bearing, rod ends bearing ,needle roller bearing,screw bearing ,slider bearings and slewing support bearings and so on.

We have exported more than 100 countries like USA, Mexico,Canada, Spain, Russia,Singapore,Thailand, India etc.We are committed to creating a one-stop shopping platform for customers to save time, improve efficiency with the best price and quality to win the trust of customers. Win-win cooperation is our company’s business philosophy.

Quality is the life of enterprise. We are committed to improving the quality of our products and services. Advanced equipment, skilled technical workers, scientific testing instrument and strict quality control, all of these factors is the key to our development and growth in the intense market competition.

Contact us now to realize the benefits of sourcing from our company. We insist to return new and old customers with best quality, fastest delivery time and most perfect after service. Your satisfaction is our goal.

| Product Feedback: |

| Product Details: |

| Product Details: |

| Product Name | Coupling |

| Feature | 1. Compact Structure |

| 2.High Strength

|

|

| 3. Long Lasting | |

| 4. Anti-corrosion | |

| 5. Easy Maintenance | |

| Precision | High Precision |

| Material |

Aluminum Alloy |

| Delivery Time | 1) 1-5 Workdays for Samples or in Stock |

| 2) 10-30 Working Days for Ordering |

| Packaging and Logistics: |

| Air freight |

| Less than 45 KGS,we will send by express. |

| (Door to Door,Convenient) |

| Land transportation |

| Between 45- 150 KGS, we will send by air transport. |

| (Fastest and safest, but expensive) |

| Railway |

| More than 150 KGS,we will send by sea. |

| Shipping |

| According to the requirement of customer. |

| Product Package: |

We at Up Gold (ZheJiang ) Automation Technology Co. LTO. can offer unrivalled product and application knowledge, we can supply ballscrew products of any size or type to our valued customer.

We place huge importance on our reputation – a reputation that seems to preceed us more and more. This reputation can only grow through good service and quality products so we’re committed to expanding our range with nothing but the best products and services and the in-house knowledge to back it all up. Of course, in-house knowledge is vitally important, not just to us, but you as a customer – so we’re proud to host some of the best people in the industry.

| Our Advantages: |

*Two-year warranty, replace instead of repair.

*12 Months Warranty

*Fast Delivery

*24 hours on line service

*Professional Team

FAQ:

Q: What is the producing process?

A: Production process including raw material cutting, machine processing,grinding, accessories cleaning, assemble, cleaning, stoving, oil coating,cover pressing, testing, package.

Q: How to control the products quality?

A: Combining advanced equipment and strict management, we provide high standard and quality bearings for our customers all over the world.

Q: What is the transportation?

A: If small quantity, we suggest to send by express, such as DHL, UPS,TNT FEDEX. If large amount, by air or sea shipping.

Q: How about the shipping charge?

A: We will be free of domestic shipping charge from your freight forwarder in China.

Q: Can you provide OEM service?

A: Yes, we provide OEM service. Which means size, quantity, design,packing solution, etc will depend on your requests; and your logo will be customized on our products.

Q: Could you tell me the delivery time of your goods?

A: Generally it is 3-5 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to the quantity.

Q: What about the packaging of your products?

A: Normally we use standard commercial package, we also have our own brand packing or customized package as per customers’ requests. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Reducing Vibration and Shock in Machinery with Elastic Couplings

Elastic couplings play a crucial role in minimizing vibration and shock in machinery by offering flexibility and damping characteristics. Here’s how they contribute to this important function:

- Vibration Absorption: Elastic couplings are designed with flexible elements that can absorb and dampen vibrations generated by rotating machinery. These flexible elements act as shock absorbers, reducing the transmission of vibrations to other parts of the system.

- Isolation: The inherent flexibility of elastic couplings isolates vibrations and shocks from one side of the coupling to the other. This prevents vibrations from propagating throughout the connected components, helping to protect sensitive equipment and improve overall system performance.

- Resonance Damping: Elastic couplings can help dampen resonance frequencies that can occur in machinery during operation. By absorbing and dissipating energy, they reduce the risk of resonance-related issues that can lead to mechanical failure or decreased efficiency.

- Smooth Torque Transmission: Elastic couplings offer a smooth torque transmission that helps reduce sudden torque spikes and shocks during start-up or sudden load changes. This prevents abrupt mechanical stresses that can lead to vibration and shock propagation.

- Increased Equipment Lifespan: By minimizing the impact of vibrations and shocks, elastic couplings contribute to the longevity of connected machinery and components. Reduced vibration-related wear and tear can extend the service life of the entire system.

Overall, elastic couplings are effective tools for managing vibration and shock in machinery, enhancing operational reliability, reducing maintenance needs, and maintaining optimal performance.

Alternatives to Elastic Couplings for Flexible Connections in Machinery

There are several alternatives to elastic couplings for achieving flexible connections in machinery:

1. Universal Joints: Universal joints, also known as U-joints, are mechanical devices that allow rotational motion between two shafts at different angles. They are suitable for applications with significant misalignment.

2. Cardan Shafts: Cardan shafts consist of a series of universal joints connected in a line, allowing for the transmission of torque and rotation in complex systems.

3. Oldham Couplings: Oldham couplings use sliding disks to transmit torque while accommodating small misalignments. They are suitable for applications where precise positioning is required.

4. Beam Couplings: Beam couplings use a flexible beam to transmit torque and compensate for angular and axial misalignment.

5. Diaphragm Couplings: Diaphragm couplings use thin diaphragms to transmit torque while compensating for misalignment. They are often used in high-performance applications.

6. Gear Couplings: Gear couplings use teethed gears to transmit torque and accommodate misalignment. They are suitable for heavy-duty applications.

7. Chain Couplings: Chain couplings use roller chains to transmit torque and handle misalignment. They are commonly used in low-speed, high-torque applications.

8. Bellows Couplings: Bellows couplings use a bellows-like flexible element to transmit torque while compensating for misalignment.

Each of these alternatives has its own advantages and limitations, and the choice depends on the specific requirements of the application.

Industries Using Elastic Couplings

Elastic couplings find extensive use in various industries due to their unique benefits:

- Industrial Manufacturing: Elastic couplings are widely used in manufacturing equipment, conveyors, and assembly lines to maintain smooth operation and reduce vibrations.

- Automotive: Automotive applications include engine components, powertrain systems, and vehicle suspension systems where flexibility and vibration dampening are crucial.

- Power Generation: Elastic couplings are used in power generation equipment such as generators, turbines, and pumps to absorb torsional vibrations and enhance efficiency.

- Aerospace: In aerospace applications, elastic couplings help dampen vibrations in critical components like aircraft engines and control systems.

- Renewable Energy: Wind turbines and solar tracking systems benefit from elastic couplings to accommodate misalignments and vibrations caused by changing wind conditions.

- Mining: Mining equipment such as crushers, conveyors, and screens utilize elastic couplings to handle varying loads and minimize shock loads.

- Marine: Elastic couplings are used in marine propulsion systems and ship equipment to manage torque fluctuations and reduce vibrations.

These industries rely on elastic couplings to enhance performance, extend machinery lifespan, and minimize downtime due to vibrations, misalignments, and shock loads.

editor by CX 2024-04-09

China Best Sales Flexible Torsionally All Steel Laminated Membrane Steel Shaft Elastic Diaphragm Coupling

Product Description

Flexible Torsionally All Steel Laminated Membrane Steel Shaft Elastic Diaphragm Coupling

Description

Metal flex couplings are disc type couplings in which several flexible metallic elements are alternately attached with bolts to opposite flanges. As polymeric elastomer is replaced by metal disc, Metal Flex coupling provides excellent temperature capability without sacrificing angular and axial misalignment. The coupling provides low axial and bending stiffness while possessing high torsional rigidity. The stretched shim pack design of CHINAMFG Metal Flex couplings provides zero backlash. CHINAMFG Metal Flex couplings are available up to 13367 Nm torque with single shim pack (UMK) and double shim pack (UMS) series.

Details

FEATURES

1.Power to weight ratio high

2.Accommodates angular and axial misalignments

3.High temperature application

4.Visual inspection is possible without dismantling equipments

5.Low axial stiffness with high torsional rigidity

6.High-speed capacity

7.Range up to 12000 Nm

8.Added advantage of stretch fitted shim pack

Our factory

Reducing Vibration and Shock in Machinery with Elastic Couplings

Elastic couplings play a crucial role in minimizing vibration and shock in machinery by offering flexibility and damping characteristics. Here’s how they contribute to this important function:

- Vibration Absorption: Elastic couplings are designed with flexible elements that can absorb and dampen vibrations generated by rotating machinery. These flexible elements act as shock absorbers, reducing the transmission of vibrations to other parts of the system.

- Isolation: The inherent flexibility of elastic couplings isolates vibrations and shocks from one side of the coupling to the other. This prevents vibrations from propagating throughout the connected components, helping to protect sensitive equipment and improve overall system performance.

- Resonance Damping: Elastic couplings can help dampen resonance frequencies that can occur in machinery during operation. By absorbing and dissipating energy, they reduce the risk of resonance-related issues that can lead to mechanical failure or decreased efficiency.

- Smooth Torque Transmission: Elastic couplings offer a smooth torque transmission that helps reduce sudden torque spikes and shocks during start-up or sudden load changes. This prevents abrupt mechanical stresses that can lead to vibration and shock propagation.

- Increased Equipment Lifespan: By minimizing the impact of vibrations and shocks, elastic couplings contribute to the longevity of connected machinery and components. Reduced vibration-related wear and tear can extend the service life of the entire system.

Overall, elastic couplings are effective tools for managing vibration and shock in machinery, enhancing operational reliability, reducing maintenance needs, and maintaining optimal performance.

Installation Guidelines for Integrating Elastic Couplings

Proper installation of elastic couplings is essential to ensure their optimal performance and longevity. Engineers should follow these guidelines:

1. Alignment: Before installation, ensure that the connected shafts are properly aligned within the manufacturer’s specified tolerances. Misalignment can lead to premature wear and reduced coupling effectiveness.

2. Lubrication: Some elastic couplings require lubrication to maintain smooth operation. Follow the manufacturer’s recommendations for the type and amount of lubricant to use.

3. Mounting: Securely mount the elastic coupling onto the shafts using appropriate torque values for the coupling’s fasteners. Use a torque wrench to prevent over-tightening, which can damage the coupling or the shafts.

4. Inspection: Inspect the coupling for any signs of damage or defects before installation. Any issues should be addressed before the coupling is put into operation.

5. Clearance: Maintain proper clearance between the coupling and surrounding components to prevent interference during operation, especially if the coupling flexes during use.

6. Environmental Factors: Consider the operating environment, such as temperature, humidity, and exposure to chemicals, when selecting an appropriate elastic coupling material.

7. Manufacturer’s Recommendations: Always refer to the manufacturer’s installation guidelines and instructions specific to the type and model of elastic coupling being used.

Following these installation guidelines will help ensure the effective and safe integration of elastic couplings into mechanical systems.

Difference Between Elastic Coupling and Rigid Coupling

Elastic couplings and rigid couplings are two distinct types of couplings used in mechanical designs:

Elastic Coupling: An elastic coupling incorporates an elastomeric material, such as rubber, to provide flexibility and absorb shock and vibration. It allows for misalignment compensation and is ideal for applications where there may be slight misalignment or the need for vibration damping. Elastic couplings are commonly used in machinery that requires smooth operation and reduced stress on connected components.

Rigid Coupling: A rigid coupling, as the name suggests, is designed to provide a solid connection between two shafts. It does not have any flexible or damping elements and is used when precise alignment and torque transmission are critical. Rigid couplings are often used in applications where shafts need to maintain a constant alignment, such as in precision machines and systems with high torque requirements.

The choice between an elastic coupling and a rigid coupling depends on the specific requirements of the mechanical system, including the degree of misalignment, vibration levels, torque transmission, and the overall performance objectives.

editor by CX 2023-10-08

China high quality High Tolerance Locking Heavy Machine Disc Elastic Flexible Elastic Diaphragm Universal Joint Disc Shaft Coupling for Paper Machinery

Product Description

High Tolerance Locking Heavy Machine Disc Elastic Flexible Elastic Diaphragm Universal Joint Disc Shaft Coupling for Paper Machinery

Metal flex couplings are disc type couplings in which several flexible metallic elements are alternately attached with bolts to opposite flanges. As polymeric elastomer is replaced by metal disc, Metal Flex coupling provides excellent temperature capability without sacrificing angular and axial misalignment. The coupling provides low axial and bending stiffness while possessing high torsional rigidity. The stretched shim pack design of CZPT Metal Flex couplings provides zero backlash. CZPT Metal Flex couplings are available up to 13367 Nm torque with single shim pack (UMK) and double shim pack (UMS) series.

FEATURES

1.Power to weight ratio high

2.Accommodates angular and axial misalignments

3.High temperature application

4.Visual inspection is possible without dismantling equipments

5.Low axial stiffness with high torsional rigidity

6.High-speed capacity

7.Range up to 12000 Nm

8.Added advantage of stretch fitted shim pack

|

Material Available |

Stainless Steel:SS201,SS301, SS303, SS304, SS316, SS416 etc. |

|

CNC Turning |

φ0.5 – φ300 * 750 mm,+/-0.005 mm |

|

CNC Milling |

510 * 1571 * 500 mm(max),+/-0.001 mm-+/-0.005 mm |

|

Surface Finish |

Aluminum:Clear Anodized,Color Anodized,Sandblast Anodized,Chemical Film,Brushing,Polishing,Chroming. |

|

Drawing Format |

IGS,STP,X_T ,DXF,DWG , Pro/E, PDF |

|

Test Equipment |

Measurement instrument, Projector, CMM, Altimeter, Micrometer, Thread Gages, Calipers, Pin Gauge etc. |

Production workshop:

Manufacturer of Couplings, Fluid Coupling, JAW Coupling, can interchange and replacement of lovejoy coupling and so on.

A coupling can interchange and replacement of lovejoy coupling is a device used to connect 2 shafts together at their ends for the purpose of transmitting power. The primary purpose of couplings is to join 2 pieces of rotating equipment while permitting some degree of misalignment or end movement or both. In a more general context, a coupling can also be a mechanical device that serves to connect the ends of adjacent parts or objects. Couplings do not normally allow disconnection of shafts during operation, however there are torque limiting couplings which can slip or disconnect when some torque limit is exceeded. Selection, installation and maintenance of couplings can lead to reduced maintenance time and maintenance cost.

Company information:

Compensation for Misalignment in Elastic Couplings

Elastic couplings are designed to accommodate certain degrees of misalignment between connected components in mechanical systems. The elastomeric material used in the coupling plays a crucial role in this compensation process:

When the two components connected by the elastic coupling experience angular, parallel, or axial misalignment, the elastomeric material deforms to a certain extent. This deformation allows the coupling to maintain its connection while absorbing the misalignment-induced stresses and forces.

The elastomer acts as a flexible link between the components, allowing them to move relative to each other within specified limits. The deformation of the elastomer also helps distribute the load more evenly, reducing stress concentrations and the risk of premature wear or damage to the coupling or connected components.

Elastic couplings can compensate for both static and dynamic misalignment, making them suitable for applications where minor misalignment is unavoidable due to factors such as manufacturing tolerances, thermal expansion, or vibration.

It’s important to note that while elastic couplings can accommodate misalignment, excessive misalignment should still be avoided, as it can lead to accelerated wear and reduced coupling lifespan. Regular inspection and maintenance are recommended to ensure that the coupling is operating within its designed limits.

Backlash in Elastic Couplings

Backlash refers to the amount of play or clearance between mating components in a mechanical system, particularly in elastic couplings. In an elastic coupling, backlash is the angular movement or rotation that occurs when there is a change in direction of the input shaft without an immediate response from the output shaft.

Backlash is a result of the elasticity and flexibility of the coupling’s components, such as the elastomer or other flexible elements. When the input direction changes, the elastic elements need to overcome their deformation before transmitting torque to the output shaft. This delay can lead to a temporary loss of motion and reduced precision in positioning applications.

Backlash can have a negative impact on the accuracy, repeatability, and overall performance of a machinery system. It can result in positioning errors, reduced responsiveness, and even potential damage to the system. Therefore, minimizing backlash is crucial in applications that require high precision and responsiveness.

Engineers can address backlash in elastic couplings by selecting couplings with lower compliance, optimizing the design to minimize the flexibility of the coupling elements, and using additional components like anti-backlash devices or preloaded mechanisms.

Industries Using Elastic Couplings

Elastic couplings find extensive use in various industries due to their unique benefits:

- Industrial Manufacturing: Elastic couplings are widely used in manufacturing equipment, conveyors, and assembly lines to maintain smooth operation and reduce vibrations.

- Automotive: Automotive applications include engine components, powertrain systems, and vehicle suspension systems where flexibility and vibration dampening are crucial.

- Power Generation: Elastic couplings are used in power generation equipment such as generators, turbines, and pumps to absorb torsional vibrations and enhance efficiency.

- Aerospace: In aerospace applications, elastic couplings help dampen vibrations in critical components like aircraft engines and control systems.

- Renewable Energy: Wind turbines and solar tracking systems benefit from elastic couplings to accommodate misalignments and vibrations caused by changing wind conditions.

- Mining: Mining equipment such as crushers, conveyors, and screens utilize elastic couplings to handle varying loads and minimize shock loads.

- Marine: Elastic couplings are used in marine propulsion systems and ship equipment to manage torque fluctuations and reduce vibrations.

These industries rely on elastic couplings to enhance performance, extend machinery lifespan, and minimize downtime due to vibrations, misalignments, and shock loads.

editor by CX 2023-09-08

China manufacturer CZPT Steps Ball Screw Clamp Series Universal Joint Elastic Single Expansion Sleeve Shrink Disc Diaphragm Coupling for Step Motor

Product Description

Ept Steps Ball Screw Clamp Series Universal Joint Elastic Single Expansion Sleeve Shrink Disc Diaphragm Coupling for Step Motor

Metal flex couplings are disc type couplings in which several flexible metallic elements are alternately attached with bolts to opposite flanges. As polymeric elastomer is replaced by metal disc, Metal Flex coupling provides excellent temperature capability without sacrificing angular and axial misalignment. The coupling provides low axial and bending stiffness while possessing high torsional rigidity. The stretched shim pack design of CZPT Metal Flex couplings provides zero backlash. CZPT Metal Flex couplings are available up to 13367 Nm torque with single shim pack (UMK) and double shim pack (UMS) series.

FEATURES

1.Power to weight ratio high

2.Accommodates angular and axial misalignments

3.High temperature application

4.Visual inspection is possible without dismantling equipments

5.Low axial stiffness with high torsional rigidity

6.High-speed capacity

7.Range up to 12000 Nm

8.Added advantage of stretch fitted shim pack

|

Material Available |

Stainless Steel:SS201,SS301, SS303, SS304, SS316, SS416 etc. |

|

CNC Turning |

φ0.5 – φ300 * 750 mm,+/-0.005 mm |

|

CNC Milling |

510 * 1571 * 500 mm(max),+/-0.001 mm-+/-0.005 mm |

|

Surface Finish |

Aluminum:Clear Anodized,Color Anodized,Sandblast Anodized,Chemical Film,Brushing,Polishing,Chroming. |

|

Drawing Format |

IGS,STP,X_T ,DXF,DWG , Pro/E, PDF |

|

Test Equipment |

Measurement instrument, Projector, CMM, Altimeter, Micrometer, Thread Gages, Calipers, Pin Gauge etc. |

Production workshop:

Manufacturer of Couplings, Fluid Coupling, JAW Coupling, can interchange and replacement of lovejoy coupling and so on.

A coupling can interchange and replacement of lovejoy coupling is a device used to connect 2 shafts together at their ends for the purpose of transmitting power. The primary purpose of couplings is to join 2 pieces of rotating equipment while permitting some degree of misalignment or end movement or both. In a more general context, a coupling can also be a mechanical device that serves to connect the ends of adjacent parts or objects. Couplings do not normally allow disconnection of shafts during operation, however there are torque limiting couplings which can slip or disconnect when some torque limit is exceeded. Selection, installation and maintenance of couplings can lead to reduced maintenance time and maintenance cost.

Company information:

Material Selection and Design Durability of Elastic Couplings

The choice of materials for elastic couplings significantly influences their design and overall durability. Material selection affects factors such as flexibility, torsional stiffness, fatigue resistance, and resistance to environmental conditions. Here’s how material selection plays a crucial role:

- Elastomer Material: The elastomer used in elastic couplings determines the coupling’s flexibility, vibration absorption capabilities, and resilience. Common elastomers include natural rubber, synthetic rubber, and polyurethane. The selected elastomer should provide the desired level of elasticity and durability while maintaining its properties over time.

- Hub and Spacer Material: The hubs and spacers of elastic couplings are typically made from metals like steel, aluminum, or alloy materials. These components need to be strong enough to transmit torque while accommodating misalignments and vibrations. The material should also resist wear, corrosion, and fatigue.

- Bolt or Pin Material: Bolts or pins used to connect the hubs and elastomer element must possess sufficient strength to handle the torsional forces and loads. They should be made from materials with high tensile strength and corrosion resistance.

- Environmental Factors: Depending on the application environment, material selection should consider factors such as temperature, moisture, chemicals, and UV exposure. The chosen materials should be able to withstand these conditions without deterioration.

Ultimately, a well-considered material selection enhances the coupling’s durability, operational performance, and resistance to wear, ensuring that the elastic coupling can reliably function under varying conditions and loads.

Impact of Temperature Variations on Elastic Coupling Performance

Elastic couplings can be sensitive to temperature variations, and their performance can be influenced by both high and low temperatures:

1. High Temperatures: Elevated temperatures can cause the elastomeric material used in elastic couplings to soften, leading to a decrease in its mechanical properties. This can result in reduced torsional stiffness, damping capabilities, and overall coupling performance. High temperatures can also accelerate the aging process of the elastomer, leading to a shorter lifespan of the coupling. Additionally, excessive heat can cause thermal expansion of the coupling’s components, potentially leading to misalignment issues.

2. Low Temperatures: Extremely low temperatures can cause the elastomeric material to become more rigid, reducing its flexibility and damping characteristics. This can result in increased transmission of vibrations and shocks between connected components. Cold temperatures can also make the elastomer more brittle, increasing the risk of cracking or rupturing under mechanical stress.

It’s important to select an elastic coupling material that is suitable for the anticipated temperature range of the application. Some elastomers are formulated to perform well across a wide temperature range, while others are better suited for specific temperature conditions. Regular maintenance and inspection of elastic couplings in extreme temperature environments are crucial to ensure that the coupling continues to function as intended.

Difference Between Elastic Coupling and Rigid Coupling

Elastic couplings and rigid couplings are two distinct types of couplings used in mechanical designs:

Elastic Coupling: An elastic coupling incorporates an elastomeric material, such as rubber, to provide flexibility and absorb shock and vibration. It allows for misalignment compensation and is ideal for applications where there may be slight misalignment or the need for vibration damping. Elastic couplings are commonly used in machinery that requires smooth operation and reduced stress on connected components.

Rigid Coupling: A rigid coupling, as the name suggests, is designed to provide a solid connection between two shafts. It does not have any flexible or damping elements and is used when precise alignment and torque transmission are critical. Rigid couplings are often used in applications where shafts need to maintain a constant alignment, such as in precision machines and systems with high torque requirements.

The choice between an elastic coupling and a rigid coupling depends on the specific requirements of the mechanical system, including the degree of misalignment, vibration levels, torque transmission, and the overall performance objectives.

editor by CX 2023-09-07

China OEM CZPT Steps Ball Screw Clamp Series Universal Joint Elastic Single Expansion Sleeve Shrink Disc Diaphragm Coupling for Step Motor

Product Description

EPT steps ball screw clamp series universal joint elastic single expansion sleeve shrink disc diaphragm coupling for step motor

Metal flex couplings are disc type couplings in which several flexible metallic elements are alternately attached with bolts to opposite flanges. As polymeric elastomer is replaced by metal disc, Metal Flex coupling provides excellent temperature capability without sacrificing angular and axial misalignment. The coupling provides low axial and bending stiffness while possessing high torsional rigidity. The stretched shim pack design of CZPT Metal Flex couplings provides zero backlash. CZPT Metal Flex couplings are available up to 13367 Nm torque with single shim pack (UMK) and double shim pack (UMS) series.

FEATURES

1.Power to weight ratio high

2.Accommodates angular and axial misalignments

3.High temperature application

4.Visual inspection is possible without dismantling equipments

5.Low axial stiffness with high torsional rigidity

6.High-speed capacity

7.Range up to 12000 Nm

8.Added advantage of stretch fitted shim pack

|

Material Available |

Stainless Steel:SS201,SS301, SS303, SS304, SS316, SS416 etc. |

|

CNC Turning |

φ0.5 – φ300 * 750 mm,+/-0.005 mm |

|

CNC Milling |

510 * 1571 * 500 mm(max),+/-0.001 mm-+/-0.005 mm |

|

Surface Finish |

Aluminum:Clear Anodized,Color Anodized,Sandblast Anodized,Chemical Film,Brushing,Polishing,Chroming. |

|

Drawing Format |

IGS,STP,X_T ,DXF,DWG , Pro/E, PDF |

|

Test Equipment |

Measurement instrument, Projector, CMM, Altimeter, Micrometer, Thread Gages, Calipers, Pin Gauge etc. |

Company Information:

Real-World Applications of Elastic Couplings

Elastic couplings find extensive use in various industries and applications where the reduction of vibration and shock is critical for performance, efficiency, and equipment longevity. Here are some examples:

- Industrial Machinery: Elastic couplings are commonly employed in industrial machinery such as pumps, compressors, conveyors, and generators. They help minimize vibration and shock, ensuring smooth and reliable operation while protecting sensitive components.

- Automotive Industry: In automotive applications, elastic couplings are used in drivetrains to dampen vibrations and shocks between the engine and the transmission. This enhances driving comfort, reduces noise, and prevents excessive wear on connected components.

- Power Generation: Power generation equipment, including turbines and generators, benefits from elastic couplings that absorb torsional vibrations and shocks. This aids in maintaining stable power output and extending the lifespan of critical components.

- Printing and Packaging: Printing presses and packaging machinery rely on elastic couplings to reduce vibrations during high-speed operations. This ensures precise printing and packaging while preventing damage to sensitive components.

- Robotics and Automation: Elastic couplings are crucial in robotics and automation systems to mitigate vibrations and shocks that can affect accuracy and reliability. They enable precise movement control and consistent performance.

- Medical Equipment: Medical devices such as MRI machines and X-ray equipment utilize elastic couplings to minimize vibrations that could impact image quality and precision during medical procedures.

These examples highlight how elastic couplings contribute to optimal performance, reduced maintenance, and increased equipment lifespan across diverse industries.

Maintaining the Longevity of Elastic Couplings

Ensuring the longevity and optimal performance of elastic couplings requires proper maintenance and care. Here are some key considerations:

- Regular Inspection: Periodically inspect the coupling for signs of wear, damage, or misalignment. Look for cracks, tears, or other deformations in the elastic elements.

- Lubrication: Some elastic couplings require lubrication for smooth operation. Follow the manufacturer’s guidelines on lubrication intervals and recommended lubricants.

- Environmental Conditions: Consider the operating environment of the coupling. Extreme temperatures, chemicals, moisture, and other factors can affect the coupling’s lifespan. Choose materials and designs suitable for the specific conditions.

- Proper Alignment: Ensure that the connected components are properly aligned to minimize excessive stress on the coupling. Misalignment can accelerate wear and reduce performance.

- Load Capacity: Do not exceed the coupling’s recommended torque and load ratings. Overloading the coupling can lead to premature failure.

- Shock and Vibration: If the system experiences frequent shock or vibration, consider using dampening or vibration-absorbing components to reduce the stress on the coupling.

- Replacement: When signs of wear or damage become noticeable, promptly replace the coupling to avoid further issues. Delaying replacement can lead to more significant problems in the machinery system.

- Follow Manufacturer Guidelines: Always follow the manufacturer’s recommendations for installation, operation, and maintenance of the specific coupling model.

By adhering to these considerations and performing regular maintenance tasks, engineers can extend the lifespan of elastic couplings and ensure reliable and efficient operation in various machinery applications.

Industries Using Elastic Couplings

Elastic couplings find extensive use in various industries due to their unique benefits:

- Industrial Manufacturing: Elastic couplings are widely used in manufacturing equipment, conveyors, and assembly lines to maintain smooth operation and reduce vibrations.

- Automotive: Automotive applications include engine components, powertrain systems, and vehicle suspension systems where flexibility and vibration dampening are crucial.

- Power Generation: Elastic couplings are used in power generation equipment such as generators, turbines, and pumps to absorb torsional vibrations and enhance efficiency.

- Aerospace: In aerospace applications, elastic couplings help dampen vibrations in critical components like aircraft engines and control systems.

- Renewable Energy: Wind turbines and solar tracking systems benefit from elastic couplings to accommodate misalignments and vibrations caused by changing wind conditions.

- Mining: Mining equipment such as crushers, conveyors, and screens utilize elastic couplings to handle varying loads and minimize shock loads.

- Marine: Elastic couplings are used in marine propulsion systems and ship equipment to manage torque fluctuations and reduce vibrations.

These industries rely on elastic couplings to enhance performance, extend machinery lifespan, and minimize downtime due to vibrations, misalignments, and shock loads.

editor by CX 2023-08-21