Product Description

Product Description

Company profile

HangZhou Terry Machinery Co.Ltd is a leading supplier of bearings, Linear motion system for CNC , Ball transfer Unit

and transmission component .the growing industrial and Favorable policy of HangZhou benefit the development of Terry

Machinery .Our products are utilized in industrial, motorcycle, vehicle and Automation applications. Now we are exporting

to 46 countries.including USA, GBR , Germany , Spain, Poland ,Turkey ect .The Goal of Terry Machinery to provide out

customers with widest range of products at competitive prices, backed with the best Service.OUR ADVANTAGE Products

Our major products & Supplied:Meet all the international standards and ISO9001 -TS1694 Certificate Big volume in Stock,

No MOQ required Personnel Our salespersons are well trained to accommodate your requests and speak English for your

conveniences.Our technicians and engineers Experience in the Industry area exceeds 23 years Service &Quality control ,

We supply detailed drawings and offer when ever necessary,We help all customers promote and improve their sales.We

inspect every piece of products by ourselves before delivery.

Customer Praise

FAQ

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Material Selection and Design Durability of Elastic Couplings

The choice of materials for elastic couplings significantly influences their design and overall durability. Material selection affects factors such as flexibility, torsional stiffness, fatigue resistance, and resistance to environmental conditions. Here’s how material selection plays a crucial role:

- Elastomer Material: The elastomer used in elastic couplings determines the coupling’s flexibility, vibration absorption capabilities, and resilience. Common elastomers include natural rubber, synthetic rubber, and polyurethane. The selected elastomer should provide the desired level of elasticity and durability while maintaining its properties over time.

- Hub and Spacer Material: The hubs and spacers of elastic couplings are typically made from metals like steel, aluminum, or alloy materials. These components need to be strong enough to transmit torque while accommodating misalignments and vibrations. The material should also resist wear, corrosion, and fatigue.

- Bolt or Pin Material: Bolts or pins used to connect the hubs and elastomer element must possess sufficient strength to handle the torsional forces and loads. They should be made from materials with high tensile strength and corrosion resistance.

- Environmental Factors: Depending on the application environment, material selection should consider factors such as temperature, moisture, chemicals, and UV exposure. The chosen materials should be able to withstand these conditions without deterioration.

Ultimately, a well-considered material selection enhances the coupling’s durability, operational performance, and resistance to wear, ensuring that the elastic coupling can reliably function under varying conditions and loads.

Alternatives to Elastic Couplings for Flexible Connections in Machinery

There are several alternatives to elastic couplings for achieving flexible connections in machinery:

1. Universal Joints: Universal joints, also known as U-joints, are mechanical devices that allow rotational motion between two shafts at different angles. They are suitable for applications with significant misalignment.

2. Cardan Shafts: Cardan shafts consist of a series of universal joints connected in a line, allowing for the transmission of torque and rotation in complex systems.

3. Oldham Couplings: Oldham couplings use sliding disks to transmit torque while accommodating small misalignments. They are suitable for applications where precise positioning is required.

4. Beam Couplings: Beam couplings use a flexible beam to transmit torque and compensate for angular and axial misalignment.

5. Diaphragm Couplings: Diaphragm couplings use thin diaphragms to transmit torque while compensating for misalignment. They are often used in high-performance applications.

6. Gear Couplings: Gear couplings use teethed gears to transmit torque and accommodate misalignment. They are suitable for heavy-duty applications.

7. Chain Couplings: Chain couplings use roller chains to transmit torque and handle misalignment. They are commonly used in low-speed, high-torque applications.

8. Bellows Couplings: Bellows couplings use a bellows-like flexible element to transmit torque while compensating for misalignment.

Each of these alternatives has its own advantages and limitations, and the choice depends on the specific requirements of the application.

Types of Elastic Couplings for Specific Applications

There are various types of elastic couplings available, each designed to suit specific industrial applications:

- Flexible Jaw Couplings: These couplings use an elastomeric element to transmit torque and accommodate misalignment. They are commonly used in applications where shock absorption and vibration damping are important, such as pumps, compressors, and conveyor systems.

- Diaphragm Couplings: Diaphragm couplings use thin metal diaphragms to transmit torque while allowing for angular, axial, and radial misalignment. They are often used in high-performance applications where precise motion transmission is required, such as in robotics, precision machinery, and aerospace systems.

- Torsional Couplings: Torsional couplings are designed to handle high torque loads and are commonly used in heavy-duty applications, including industrial machinery, mining equipment, and large pumps.

- Disc Couplings: Disc couplings use multiple thin metal discs to transmit torque and accommodate misalignment. They are suitable for applications requiring high torque transmission and precise motion control, such as turbines, generators, and high-speed machinery.

- Beam Couplings: Beam couplings use helical cuts in a flexible beam to provide torsional flexibility and misalignment compensation. They are used in applications that require moderate torque transmission and misalignment accommodation, such as stepper motors and motion control systems.

- Oldham Couplings: Oldham couplings use three disks to transmit torque while allowing for axial misalignment. They are commonly used in applications that require accurate motion transmission, such as linear actuators and CNC machinery.

The choice of the right type of elastic coupling depends on factors such as the application’s torque requirements, speed, misalignment characteristics, and specific performance needs.

editor by CX 2024-05-16

China OEM FCL224 Cast Iron Flexible Coupling Elastic Sleeve Pin Couplings FCL Rubber Couplings

Product Description

Product Description

Company profile

HangZhou Terry Machinery Co.Ltd is a leading supplier of bearings, Linear motion system for CNC , Ball transfer Unit

and transmission component .the growing industrial and Favorable policy of HangZhou benefit the development of Terry

Machinery .Our products are utilized in industrial, motorcycle, vehicle and Automation applications. Now we are exporting

to 46 countries.including USA, GBR , Germany , Spain, Poland ,Turkey ect .The Goal of Terry Machinery to provide out

customers with widest range of products at competitive prices, backed with the best Service.OUR ADVANTAGE Products

Our major products & Supplied:Meet all the international standards and ISO9001 -TS1694 Certificate Big volume in Stock,

No MOQ required Personnel Our salespersons are well trained to accommodate your requests and speak English for your

conveniences.Our technicians and engineers Experience in the Industry area exceeds 23 years Service &Quality control ,

We supply detailed drawings and offer when ever necessary,We help all customers promote and improve their sales.We

inspect every piece of products by ourselves before delivery.

Customer Praise

FAQ

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Real-World Applications of Elastic Couplings

Elastic couplings find extensive use in various industries and applications where the reduction of vibration and shock is critical for performance, efficiency, and equipment longevity. Here are some examples:

- Industrial Machinery: Elastic couplings are commonly employed in industrial machinery such as pumps, compressors, conveyors, and generators. They help minimize vibration and shock, ensuring smooth and reliable operation while protecting sensitive components.

- Automotive Industry: In automotive applications, elastic couplings are used in drivetrains to dampen vibrations and shocks between the engine and the transmission. This enhances driving comfort, reduces noise, and prevents excessive wear on connected components.

- Power Generation: Power generation equipment, including turbines and generators, benefits from elastic couplings that absorb torsional vibrations and shocks. This aids in maintaining stable power output and extending the lifespan of critical components.

- Printing and Packaging: Printing presses and packaging machinery rely on elastic couplings to reduce vibrations during high-speed operations. This ensures precise printing and packaging while preventing damage to sensitive components.

- Robotics and Automation: Elastic couplings are crucial in robotics and automation systems to mitigate vibrations and shocks that can affect accuracy and reliability. They enable precise movement control and consistent performance.

- Medical Equipment: Medical devices such as MRI machines and X-ray equipment utilize elastic couplings to minimize vibrations that could impact image quality and precision during medical procedures.

These examples highlight how elastic couplings contribute to optimal performance, reduced maintenance, and increased equipment lifespan across diverse industries.

Contribution of Elastic Couplings to Rotating System Efficiency

Elastic couplings play a significant role in enhancing the overall efficiency of rotating systems by providing various benefits:

1. Vibration Damping: Elastic couplings absorb and dampen vibrations and shocks that arise from the operation of rotating machinery. By minimizing these vibrations, elastic couplings reduce wear and tear on components, leading to smoother operation and extended component lifespan.

2. Misalignment Compensation: Rotating systems often experience misalignments due to factors like thermal expansion, installation errors, or operational conditions. Elastic couplings can accommodate angular, axial, and radial misalignments, ensuring consistent power transmission and reducing stress on connected components.

3. Shock Absorption: In applications with sudden starts, stops, or load changes, elastic couplings absorb and distribute shock loads. This prevents sudden jolts that could damage the machinery or cause mechanical failures.

4. Torsional Vibration Reduction: Elastic couplings help minimize torsional vibrations, which can lead to resonance and cause structural damage. By damping these vibrations, elastic couplings prevent energy loss and ensure smooth operation.

5. Energy Efficiency: The ability of elastic couplings to reduce vibrations, misalignments, and shock loads leads to improved energy efficiency. The machinery experiences fewer energy losses due to internal friction and component stress.

Elastic couplings enhance the reliability, longevity, and performance of rotating systems, ultimately leading to reduced downtime, maintenance costs, and overall operational inefficiencies.

Benefits of Using Elastic Couplings in Industrial Machinery

Elastic couplings offer several advantages when used in industrial machinery:

- Misalignment Compensation: Elastic couplings can accommodate small angular, axial, and radial misalignments between connected shafts. This ability to compensate for misalignment helps prolong the life of machinery components and reduces the risk of premature wear.

- Vibration Damping: The elastic element in the coupling absorbs and dampens vibrations generated during operation. This feature improves the overall smoothness of machinery operation, reduces noise, and minimizes the transmission of vibrations to other parts of the system.

- Shock Absorption: Elastic couplings absorb sudden shocks or impacts that may occur during operation. By reducing the impact load on the connected components, the coupling helps prevent damage and extends the lifespan of the machinery.

- Reduced Maintenance: The flexibility and shock-absorbing properties of elastic couplings contribute to lower maintenance requirements. Machinery components experience less stress and wear, resulting in longer intervals between maintenance tasks.

- Protection of Equipment: Elastic couplings act as a protective barrier between connected machinery. They isolate vibrations and shocks, preventing these forces from propagating throughout the system and potentially causing damage.

- Improved Efficiency: By minimizing misalignment-related losses and reducing vibrations, elastic couplings contribute to improved machinery efficiency. This can lead to energy savings and better overall performance.

In summary, elastic couplings play a crucial role in enhancing the reliability, longevity, and efficiency of industrial machinery by addressing misalignment, dampening vibrations, absorbing shocks, and minimizing maintenance needs.

editor by CX 2024-05-08

China Custom CFC Shaft Coupling PU Rubber Flexible Elastic Spiders Coupling Plum Shaft Couplings for Jaw Bush Shaft Coupler

Product Description

Excellent powder metallurgy parts metallic sintered parts

We could offer various powder metallurgy parts including iron based and copper based with top quality and cheapest price, please only send the drawing or sample to us, we will according to customer’s requirement to make it. if you are interested in our product, please do not hesitate to contact us, we would like to offer the top quality and best service for you. thank you!

How do We Work with Our Clients

1. For a design expert or a big company with your own engineering team: we prefer to receive a fully RFQ pack from you including drawing, 3D model, quantity, pictures;

2. For a start-up company owner or green hand for engineering: just send an idea that you want to try, you don’t even need to know what casting is;

3. Our sales will reply you within 24 hours to confirm further details and give the estimated quote time;

4. Our engineering team will evaluate your inquiry and provide our offer within next 1~3 working days.

5. We can arrange a technical communication meeting with you and our engineers together anytime if required.

| Place of origin: | Jangsu,China |

| Type: | Powder metallurgy sintering |

| Spare parts type: | Powder metallurgy parts |

| Machinery Test report: | Provided |

| Material: | Iron,stainless,steel,copper |

| Key selling points: | Quality assurance |

| Mould type: | Tungsten steel |

| Material standard: | MPIF 35,DIN 3571,JIS Z 2550 |

| Application: | Small home appliances,Lockset,Electric tool, automobile, |

| Brand Name: | OEM SERVICE |

| Plating: | Customized |

| After-sales Service: | Online support |

| Processing: | Powder Metallurgr,CNC Machining |

| Powder Metallurgr: | High frequency quenching, oil immersion |

| Quality Control: | 100% inspection |

The Advantage of Powder Metallurgy Process

1. Cost effective

The final products can be compacted with powder metallurgy method ,and no need or can shorten the processing of machine .It can save material greatly and reduce the production cost .

2. Complex shapes

Powder metallurgy allows to obtain complex shapes directly from the compacting tooling ,without any machining operation ,like teeth ,splines ,profiles ,frontal geometries etc.

3. High precision

Achievable tolerances in the perpendicular direction of compacting are typically IT 8-9 as sintered,improvable up to IT 5-7 after sizing .Additional machining operations can improve the precision .

4. Self-lubrication

The interconnected porosity of the material can be filled with oils ,obtaining then a self-lubricating bearing :the oil provides constant lubrication between bearing and shaft ,and the system does not need any additional external lubricant .

5. Green technology

The manufacturing process of sintered components is certified as ecological ,because the material waste is very low ,the product is recyclable ,and the energy efficiency is good because the material is not molten.

FAQ

Q1: What is the type of payment?

A: Usually you should prepay 50% of the total amount. The balance should be pay off before shipment.

Q2: How to guarantee the high quality?

A: 100% inspection. We have Carl Zeiss high-precision testing equipment and testing department to make sure every product of size,appearance and pressure test are good.

Q3: How long will you give me the reply?

A: we will contact you in 12 hours as soon as we can.

Q4. How about your delivery time?

A: Generally, it will take 25 to 35 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order. and if the item was non standard, we have to consider extra 10-15days for tooling/mould made.

Q5. Can you produce according to the samples or drawings?

A: Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

Q6: How about tooling Charge?

A: Tooling charge only charge once when first order, all future orders would not charge again even tooling repair or under maintance.

Q7: What is your sample policy?

A: We can supply the sample if we have ready parts in stock, but the customers have to pay the sample cost and the courier cost.

Q8: How do you make our business long-term and good relationship?

A: 1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Maintenance Requirements for Optimal Performance of Elastic Couplings

Maintaining elastic couplings is essential to ensure their optimal performance and longevity. Following these maintenance guidelines can help prevent premature wear and failure:

- Regular Inspection: Periodically inspect the coupling for signs of wear, such as cracks, deformities, or visible damage. This can help identify issues early and prevent further damage.

- Lubrication: Some elastic couplings require lubrication to reduce friction and wear. Follow the manufacturer’s recommendations for lubrication intervals and use compatible lubricants.

- Torque Check: Check the coupling’s torque values to ensure they are within the specified range. This helps maintain proper torque transmission and prevents overloading.

- Alignment Check: Monitor the alignment of the connected shafts regularly. Misalignment can cause excessive stress on the coupling, leading to premature failure.

- Vibration Analysis: Perform vibration analysis to identify any abnormal vibrations in the system. Excessive vibrations could indicate coupling or system issues that need attention.

- Temperature and Environment: Ensure that the coupling operates within the recommended temperature and environmental limits. Extreme conditions can affect the coupling’s material properties and performance.

- Coupling Wear: Keep track of the coupling’s wear over time. Depending on the application, the coupling might need replacement after a certain period of service.

- Expert Inspection: If any unusual symptoms or problems arise, consider having the coupling inspected by a qualified technician or engineer to diagnose the issue accurately.

Adhering to these maintenance practices helps extend the service life of elastic couplings, ensures reliable performance, and minimizes unexpected downtime and costly repairs.

Installation Guidelines for Integrating Elastic Couplings

Proper installation of elastic couplings is essential to ensure their optimal performance and longevity. Engineers should follow these guidelines:

1. Alignment: Before installation, ensure that the connected shafts are properly aligned within the manufacturer’s specified tolerances. Misalignment can lead to premature wear and reduced coupling effectiveness.

2. Lubrication: Some elastic couplings require lubrication to maintain smooth operation. Follow the manufacturer’s recommendations for the type and amount of lubricant to use.

3. Mounting: Securely mount the elastic coupling onto the shafts using appropriate torque values for the coupling’s fasteners. Use a torque wrench to prevent over-tightening, which can damage the coupling or the shafts.

4. Inspection: Inspect the coupling for any signs of damage or defects before installation. Any issues should be addressed before the coupling is put into operation.

5. Clearance: Maintain proper clearance between the coupling and surrounding components to prevent interference during operation, especially if the coupling flexes during use.

6. Environmental Factors: Consider the operating environment, such as temperature, humidity, and exposure to chemicals, when selecting an appropriate elastic coupling material.

7. Manufacturer’s Recommendations: Always refer to the manufacturer’s installation guidelines and instructions specific to the type and model of elastic coupling being used.

Following these installation guidelines will help ensure the effective and safe integration of elastic couplings into mechanical systems.

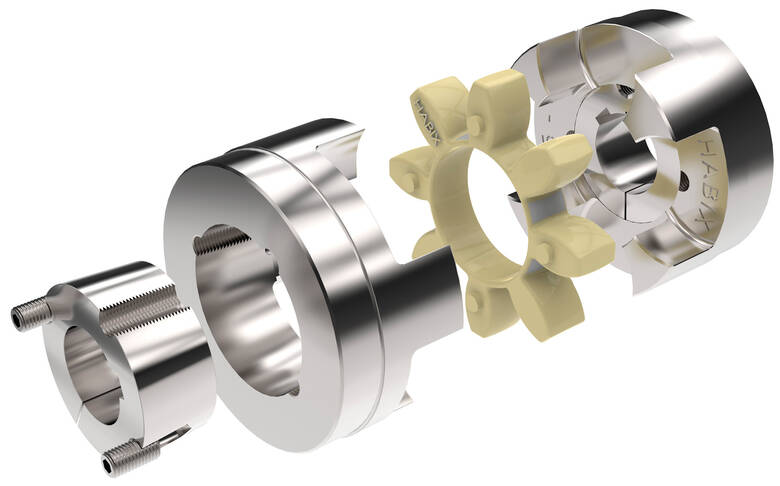

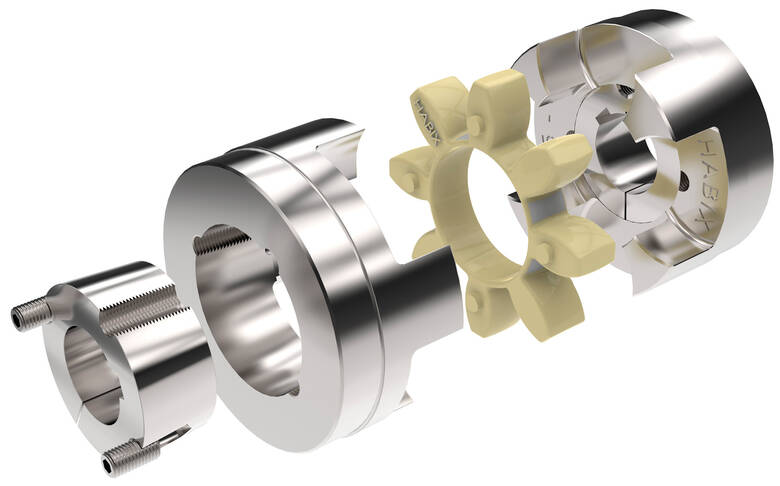

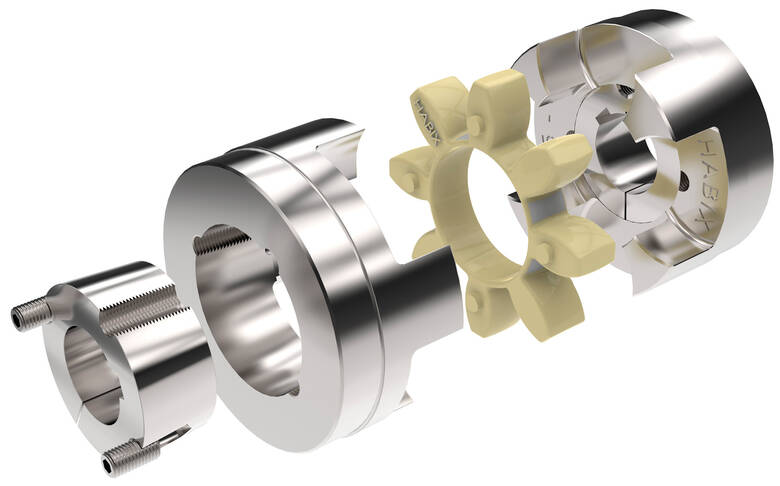

Elastic Coupling: Function and Working in Mechanical Systems

An elastic coupling is a type of coupling used in mechanical systems to connect two shafts and transmit torque while allowing for a certain degree of misalignment and flexibility. It consists of two hubs, each connected to a shaft, and an elastic element placed between the hubs.

The elastic element, often made of rubber or elastomer material, serves as a flexible medium that can absorb shocks, vibrations, and angular misalignments between the connected shafts. When torque is applied to one shaft, the elastic element deforms and compresses, allowing the coupling to transmit torque from one shaft to the other while compensating for minor misalignments.

As the elastic element absorbs vibrations and shocks, it helps reduce wear and tear on the connected machinery and enhances overall system efficiency. Elastic couplings are commonly used in applications where precise alignment between shafts is challenging or where vibration damping is crucial.

Overall, the elastic coupling’s design enables it to provide a balance between torque transmission and flexibility, making it a valuable component in various mechanical systems.

editor by CX 2024-04-30

China Custom FCL224 Cast Iron Flexible Coupling Elastic Sleeve Pin Couplings FCL Rubber Couplings

Product Description

Product Description

Company profile

HangZhou Terry Machinery Co.Ltd is a leading supplier of bearings, Linear motion system for CNC , Ball transfer Unit

and transmission component .the growing industrial and Favorable policy of HangZhou benefit the development of Terry

Machinery .Our products are utilized in industrial, motorcycle, vehicle and Automation applications. Now we are exporting

to 46 countries.including USA, GBR , Germany , Spain, Poland ,Turkey ect .The Goal of Terry Machinery to provide out

customers with widest range of products at competitive prices, backed with the best Service.OUR ADVANTAGE Products

Our major products & Supplied:Meet all the international standards and ISO9001 -TS1694 Certificate Big volume in Stock,

No MOQ required Personnel Our salespersons are well trained to accommodate your requests and speak English for your

conveniences.Our technicians and engineers Experience in the Industry area exceeds 23 years Service &Quality control ,

We supply detailed drawings and offer when ever necessary,We help all customers promote and improve their sales.We

inspect every piece of products by ourselves before delivery.

Customer Praise

FAQ

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Maintenance Requirements for Optimal Performance of Elastic Couplings

Maintaining elastic couplings is essential to ensure their optimal performance and longevity. Following these maintenance guidelines can help prevent premature wear and failure:

- Regular Inspection: Periodically inspect the coupling for signs of wear, such as cracks, deformities, or visible damage. This can help identify issues early and prevent further damage.

- Lubrication: Some elastic couplings require lubrication to reduce friction and wear. Follow the manufacturer’s recommendations for lubrication intervals and use compatible lubricants.

- Torque Check: Check the coupling’s torque values to ensure they are within the specified range. This helps maintain proper torque transmission and prevents overloading.

- Alignment Check: Monitor the alignment of the connected shafts regularly. Misalignment can cause excessive stress on the coupling, leading to premature failure.

- Vibration Analysis: Perform vibration analysis to identify any abnormal vibrations in the system. Excessive vibrations could indicate coupling or system issues that need attention.

- Temperature and Environment: Ensure that the coupling operates within the recommended temperature and environmental limits. Extreme conditions can affect the coupling’s material properties and performance.

- Coupling Wear: Keep track of the coupling’s wear over time. Depending on the application, the coupling might need replacement after a certain period of service.

- Expert Inspection: If any unusual symptoms or problems arise, consider having the coupling inspected by a qualified technician or engineer to diagnose the issue accurately.

Adhering to these maintenance practices helps extend the service life of elastic couplings, ensures reliable performance, and minimizes unexpected downtime and costly repairs.

Alternatives to Elastic Couplings for Flexible Connections in Machinery

There are several alternatives to elastic couplings for achieving flexible connections in machinery:

1. Universal Joints: Universal joints, also known as U-joints, are mechanical devices that allow rotational motion between two shafts at different angles. They are suitable for applications with significant misalignment.

2. Cardan Shafts: Cardan shafts consist of a series of universal joints connected in a line, allowing for the transmission of torque and rotation in complex systems.

3. Oldham Couplings: Oldham couplings use sliding disks to transmit torque while accommodating small misalignments. They are suitable for applications where precise positioning is required.

4. Beam Couplings: Beam couplings use a flexible beam to transmit torque and compensate for angular and axial misalignment.

5. Diaphragm Couplings: Diaphragm couplings use thin diaphragms to transmit torque while compensating for misalignment. They are often used in high-performance applications.

6. Gear Couplings: Gear couplings use teethed gears to transmit torque and accommodate misalignment. They are suitable for heavy-duty applications.

7. Chain Couplings: Chain couplings use roller chains to transmit torque and handle misalignment. They are commonly used in low-speed, high-torque applications.

8. Bellows Couplings: Bellows couplings use a bellows-like flexible element to transmit torque while compensating for misalignment.

Each of these alternatives has its own advantages and limitations, and the choice depends on the specific requirements of the application.

Types of Elastic Couplings for Specific Applications

There are various types of elastic couplings available, each designed to suit specific industrial applications:

- Flexible Jaw Couplings: These couplings use an elastomeric element to transmit torque and accommodate misalignment. They are commonly used in applications where shock absorption and vibration damping are important, such as pumps, compressors, and conveyor systems.

- Diaphragm Couplings: Diaphragm couplings use thin metal diaphragms to transmit torque while allowing for angular, axial, and radial misalignment. They are often used in high-performance applications where precise motion transmission is required, such as in robotics, precision machinery, and aerospace systems.

- Torsional Couplings: Torsional couplings are designed to handle high torque loads and are commonly used in heavy-duty applications, including industrial machinery, mining equipment, and large pumps.

- Disc Couplings: Disc couplings use multiple thin metal discs to transmit torque and accommodate misalignment. They are suitable for applications requiring high torque transmission and precise motion control, such as turbines, generators, and high-speed machinery.

- Beam Couplings: Beam couplings use helical cuts in a flexible beam to provide torsional flexibility and misalignment compensation. They are used in applications that require moderate torque transmission and misalignment accommodation, such as stepper motors and motion control systems.

- Oldham Couplings: Oldham couplings use three disks to transmit torque while allowing for axial misalignment. They are commonly used in applications that require accurate motion transmission, such as linear actuators and CNC machinery.

The choice of the right type of elastic coupling depends on factors such as the application’s torque requirements, speed, misalignment characteristics, and specific performance needs.

editor by CX 2024-04-24

China Professional PU Rubber Spider / Shaft Couplings with high quality

Product Description

Merchandise description

|

Material |

Materials for silicon,fluorine,NBR,FPM,EPDM,SILCONE ACM,HNBR |

| Inspection Equipments | Excellent chemical and bodily home, superb oil- resistance, high temperature stability, and so on. |

| Tolerance | +/-.05mm |

| Drawing Structure | PDF/DWG/DXF/IGS/Phase,and so on |

| Application field | Parts are utilised on cars, printing machines, foods processing machines, textile machines, electronic equipment, and so forth. |

| Production process | CNC machining Broaching, Drilling, Milling, Other Machining Services, Rapid Prototyping, Turning, |

| Form | As per your drawing Or your sample |

| Color service | Customization |

| QC inspection |

Make sure one hundred% inspection before the shipping |

| Advantages | Upkeep,acturally HRC CZPT doesn’t need maintenance. |

| Environmental, elastic factors make HRC CZPT applies to a range of operating problems. | |

|

Reputable transmission, in situation of elastic ingredient is ruined, the pet section wichcasted siamesedly even now keep the transmission processing reliably. |

|

|

Economic, HRC couplings have presently been manufactured of optimization design,which make transmission electricity match the transmission shaft diameter. |

|

| Great restoration capacity, elastic components can decrease the load at the peak moments, and the deviation is a significant thing to consider when designing. | |

|

Adaptability of misalignment, HRC can CZPT is made up of parallel change, angle shift and axis shift which happen some instances. |

Software and analysis

Our warehouse

Customized rubber areas

Custom plastic elements

Packing & Supply

Packaging Details: plastic bag packing inside, carton packing outside, or tailored packing.

Port:Xihu (West Lake) Dis.g port, ZheJiang city.

Direct Time :

| Amount(Parts) | one – 1000 | 1001 – ten thousand | 10001 – 50000 | >50000 |

| Est. Time(times) | 5 | 12 | eighteen | To be negotiated |

Area get measures

Our Solutions:

one. Convenient: 24th Several hours sales/Right after-revenue Support on the web or on the telephone.

two. Quality Assurance: We will discuss with you and provide you the greatest quality relaxed to your industry.

3. Rapid shipping and delivery: Time is funds, we guarantee we usually will deliver the items a lot quicker than other folks.

4. According to customers’ drawing,personalized specs are welcomed.

five. Tiny orders can be acknowledged.

Packing

Firm Profile

SHEN ZHOU CZPT RUBBER & PLASTIC CO.,LTD was launched in 2000. The factory positioned in industrial zone of HangZhou metropolis, ZheJiang province, china.

We have Plastic injection molding workshop and rubber compression molding workshops.Our main items consists of Bakelit Knobs,Pull Manage,rubber door stops, doorway guard, roller, rubber bumpers, Rubber grommets, vibration dampers, seals, plastic corner, injection plastic brackets, injection plastic shell.to undertake different varieties of rubber molding and plastic injection components, customize according to drawing and samples.

The merchandise have been exported to America, Europe, Oceania, Center East, Southeast Asia and other areas and nations, and hope to develop much more organization Cooperation with new customer from all in excess of the globe.

FAQ

Q1: Are you a manufacturer or a trading firm?

A1: We are the authentic company of customized rubber elements and customized plastic elements.

Q2: In which is your company found?

A2: Our organization is found in HangZhou Metropolis, ZheJiang Province, China.

Q3: Could I get totally free samples?

A3: We could give little samples for free, but air freight or sea freight should be borne by customer aspect.

This fall: What should I provide in get to get an provide?

A4: Consumers are necessary to supply content, interior diameter, outer diameter, CZPT section length and quantity.

Q5: How is the items packed by your manufacturing facility?

A5: The merchandise are normally packed by plastic bags, carton packing containers with pallets or picket containers.

Q6: What are the incoterms utilized?

A6: The incoterms used are FOB, CIF and CFR.

Q7: What are the payment conditions recognized?

A7: We take Alibaba Trade Assurance, T/T, L/C and West Union.

Q8: What about the shipping time?

A8: The products are typically dellivered to client side inside of 7-30 times primarily based on the mode of transport essential.

Content flex couplings usually do not require lubrication and function in shear or compression, and can acknowledge angular, parallel, and axial misalignment. Examples of materials elastic couplings are jaw, sleeve, tire, disc, mesh, and diaphragm couplings.

Disc couplings perform by transmitting torque by way of curved disc components. It operates by rigidity and compression of chord segments on a widespread bolt circle bolted alternately amongst the travel side and the drive facet. These couplings usually consist of two hubs, two-disc packs, and a middle member. Single disc assemblies accommodate angular and axial misalignment. Two-disc assemblies are required to accommodate parallel misalignment. Permits angular parallel and axial misalignment, is a true finite stop float style, zero-backlash style, large velocity rated and well balanced

China Good quality Rubber Flexible Couplings for Air Compressor Parts CZPT Copco CZPT Sullair CZPT Rand CZPT CZPT Compair CZPT Bolaite CZPT CZPT with Best Sales

Solution Description

Rubber Versatile Couplings for Air Compressor CZPT CZPT Sullair CZPT Rand CZPT CZPT Compair CZPT Bolaite HongHangZhouan Hitachi

Item Display:

Business data:

YINGFENG Design Machinery Limited / HangZhou CZPT Equipment CO., LTD specialized in:

couplings, rubber mounts, gear components , hydraulic seals and seal kits for hydraulic hammers, rock breakers, hydraulic excavators, wheel loaders, and backhoe loaders.

And, Our Company also offer:

Motor Elements, hydraulic piston pump and hydraulic vacation motor, Swing motor assembly and hydraulic part elements, electric powered parts, and so on. Hydraulic hammer breaker parts with piston, cylinder, chisel, by means of bolt, facet bolt, prime bush, front head bushing, accumulator, valve, and so on.

The pursuing seal kits we also can supply:

1.Principal pump seal package

2.Hydraulic pump seal kit

3.Regulater valve seal kit

four.Plunger pump seal kit

five.O ring box

6.Equipment pump seal restore kit,

seven.Vacation motor seal kit

8.Breaker hammer seal package

9.Swing motor seal kit,

ten.Lever seal kit

11.Pilot valve seal package/PPC seal

12.Adjuster seal kit

thirteen.Middle joint seal package

14.Turing joint seal kit

fifteen.Servo valve seal package

sixteen.Increase cylinder seal package

seventeen.Arm cylinder seal kit

18.Bucket cylinder seal package

19.Manage valve seal package.

We usually try out our greatest for all our buyers and make it better and better. Welcome!

A. A lot more than 20 yease experience in the line of the marketplace, create large good quality excavator spare parts.

B. Manufacturing facility company, manufacturing facility price tag, quality under handle.

C. A single-cease shopping. We source with a variety of spare elements for your require, with high top quality at aggressive value, one-cease searching, conserve your time to searching the areas you need urgent.

D. Timely shipping. ( We can handle your urgent purchase inside of 24 several hours as quickly as we received the payment. And We will send the areas by DHL and Fedex Express. We will need Element delivery tackle with postcodebefore shipment. So, It will be much better if you cound discover us about it in progress.)

E. Various of transportation way: Sea, Air, Bus, Convey, and so forth

F. Components available in inventory

OUR Manufacturing unit:

Our excavator areas factory was set up in 1988 in HangZhou metropolis,ZheJiang Province. And in calendar year 2011 we set up the 2nd manufacturing facility. Now we are the greatest excavator rubber components provider in southern China. Factory occupies ten,000 sq. meters and has a number of full sets of excavator components manufacturing line with eighty skilled employees and 3-million once-a-year creation potential.

Manufacturing unit supervisor Mr.Zhang has 24years excavator parts industrial & manufacturing experience.Factory R&D and QC staff are wealthy skilled in excavator areas manufacturing line.

Our office and group:

Merchandise & services:

A.Hydraulic Breaker Seals, Seal Kits and Hyd. Hammer Components

B.Hydraulic Seals & Seal Kits & Spare Areas for Excavator Hyd. Cylinder, Hydraulic Pump, Swing Motor, Vacation Motor, Principal Management Valve MCV, Diesel Engine

Certificates:

Q&A:

1. What is you core action (do you deal with motor substitute elements, fuel program, undercarriage, etc)?

We largely do the couplings, seal kits, electric elements, equipment components and bearings.

2. Which type of equipment you operate with (bulldozers, front loaders, graders, excavators, and many others)?

Excavators

3. Which makes of equipment you operate with?

We supply areas for brand names like: Hitachi, Caterpillar, Komatsu, Sumitomo, Hyundai, Kobelco, Liebherr, JCB, and so on.

We mostly do modest to meddium dimensions excavators.

4. Do you have the inventory?

Most of our items are in inventory.

5. Can you deliver us the cost lists (so that we do not often hassle you when we need to have the price info)?

Sorry that we will not have value listing. You might be welcomed to speak to us if you need something.

6. If we make the order, can we shell out as the an specific? Or we must make the agreement for every shipping and delivery?

We take Western Union, PayPal, T/T.

For small buy, we advocate Western Union and PayPal.

For PayPal, you are going to need to pay out extra 5% of total volume to include the PayPal price.

For T/T, you will need to spend extra 50USD to protect the bank demand and dealing with price if purchase less than 1000USD.

seven. What is your typical way of delivery?

Typically we send out with DHL, UPS, EMS. We also send by sea by bulk purchase.

To Russia, We can also ship with Russian line. Russian line is a shipment way sent by truck and prepare.

Hot sale merchandise recomendation:

Original Excavator Components CZPT CF-A series Rubber Adaptable Torsionally Shaft CZPT for Centaflex

What couplings model we produce?

We have sevrel couplings series including:

A/AS series, H series, G/C series, T series, S series, I series, Clutch series, HO series, Spline series,

Gear Hub series, etc.

What machines do our couplings use on?

Our couplings are widely use on diesel engines, front power take off, gensets, compressors, air compressors, pumps, boat drives, hydraulic pumps on diesel engines & hydrostatic construction drives: excavator, vibratory rollers, cranes, dumpers, forklifts, concrete mixers and pumps, road finishers, rail cars, agricultural machines, tractors, small compressors

Details of Our Couplings Series: The couplings we provide can be used on machine model as follow:

Bobcat: 337, 311, 331

Case: CASE360

Caterpillar: E70B, E307, E308, E70B, 308B, E140, E120, E312, E120B, E311, E320, E320B, E320C, E325, E330, E240B(3116T), E240, CAT322, E240B, E325C, E330, E330D, 324-4415, 324-4451, 239-6479, 289-0169, C9, E330DL E330DN, 320D, 7Y-0643, 305-4951,305-4952, 374-6053, E352C, E485 , E330C, E320C, E320D, E345B, E325B, E200B

Daewoo: DH35, DH280, DH55 DH550, DH80-7, DH225-7, DH220-5, DH258-7, DH150-5, DH130-3, DH220-3, DH300 , DH320 , DH280, DH300-7, DH215-9, DH225-9, DH370, DH70, DX300LC,

Hitachi: EX55, EX55, EX40, EX100, EX120, EX400, EX120-2, UH052, UH053, UH04-7, UH045-7, UH04-5, EX60-1, EX90, ZAX60, ZAX120, ZAX70, EX120-6, EX200-2 EX220-2, EX200-5, EX120-2, EX120-3, EX120-5, ZAX240, EX200-6, ZAX270, ZAX200, EX220, EX220-1, EX200-1, EX200-3, EX200-5, 4334891, 4655134, EX300, EX300-5, ZAX330, EX270, ZAX360, ZAX350-3G/F, EX400, EX200-6, ZX450 ZAX330-3 4456914, ZAX460MTH, ZAX480MTH, 4636444, ZX470-3, EX470, ZAX470, ZAX450-3, ZAX450-3F, ZAX500LC-3F, ZAX520LC-3F, ZAX520LCH-3F, ZAX350K-3, ZAX330-3, ZAX250H-3, ZAX250K-3, ZAX210K-3

Hyundai: R60, R200 R210, R225-7, R215-7, R300 , R305-7,

JCB: JCB210, JCB330LC, JCB JS200, JRJ5713, JCB240, JCB260

John Deere: 790D, John Deere 1571D, 1110D, 1400D,

Kato: HD250-1, HD250-5, HD250-7, HD400SEV, HD450SEV, HD700, HD800, HD880-1, HD1250 HD850, HD2045

Komatsu: 10E-sixty-25130, PC10-1, PC20, PC30, WA30-1, PC10, PC20, PC30, PC40-7, PC40, PC35, PC50, PC30-5, 20T-01-31110, 3D95S-W-1C BM571C-1 CD30R-1 GC50-1 PC20-3 PC25-1 PC25R-1 PC30-1 PC30-3 PC30-5 PC30-6 PC30-7 PC30R-7 PC30R-8 PC35MR-1 PC35MRX-1A PC35R-8 PC38UU-1 PC38UU-2 PC38UU-3 PC38UUM-2 PC40-1 PC40-2 PC40-3 PC40-5 PC40-6 PC40-7 PC40MR-1 PC40MR-2 PC40MRX-1 PC40R-8 PC40T-7 PC45-1 PC45MR-1 PC45MRX-1 PC45R-8 PC50MR-2-AC PC50MR-2 PC50UD-2 PC50UG-2 PC50UU-2 PC50UUM-2 PC58SF-1 PC58SF-1 PC58UU-3 PW30-1 PW30T-1 WA20-2 WA30-5-CB WA30-5-CN WA30-5-X WA30-5 WA30-5 WA40-3-CB WA40-3-CN WA40-3-X WA40-3 WA50-3-CB WA50-3-CN WA50-3-X WA50-3 WA50-3 WA50-3 WA50-6, PC40-5, PC200-1, PC200-2, PC300-1 PC300

Kobelco: SK03, SK04, SK04N, SK40, SK50UR, SK03, SK100-2, SK100-5, SK60, SK03, SK75, SK120-1, SK120-3, SK120, SK60, SK120-3 , SK460-8 SK200, SK07N2, SK230, SK200-6(YN30P57102F2), SK200-6, SK250, SK230, SK200-7, SK250-8, SK220-3(6D16 2418R219S1), SK220-3(6D14), SK230(6D34), SK230-6(6D34), SK320-6(2418R219S1)SK350-8, SK07 SK09 SK12 ,SK300, SK400, NEWHOLLAND CZPT (Portion #: LS30P57104F1), SK480

SK450 HD1243 2418R660S001 LS30P57163F1 SK460-8 SK480LC-8 LS30P57163S004 LS30P57163S003 SK400LC-IV K3V180DT LS30P57163P1 K5V200DTP,

Mitsubishi: MS070-8 MS120-1, MS120-2, MS140-8 MS110

Sumitomo: SH60, SH160, SH120, SH100 , SH260, SH135 SH265, LS3400, SH280-1 SH280-2, LS4300EJ, SH130-5, SH75, SH330 KTJ2234 SH340 SH350, SH460, SH30, SH200

Volvo: EC60, EC210

Other individuals: VH25-7, EM100 ,ROS R1100, PDS750, PDS850, BOMAG212D, 5985712, CZPT Copco, 3222307839,

HPV102, 8DC8 8DC9, CZPT TierII 522192, Xihu (West Lake) Dis.de 60, PERKINS 1006-6T, BOMAG BW 213 DH-3, SAKAI SV512D(ROLLER) , Takeuchi one hundred seventy five, CZPT 6BT5.9, K5V200, 45571, 1615622900,

Atlas Copco 385, CZPT 396, CZPT 415, CZPT 416, CZPT 455, CZPT 485,

Atlas Copco 486, CZPT 786, CZPT 836, CZPT 976, CZPT 600, CZPT 560, CZPT VIO75, VIO70, 172187-71200, 1615682500, 4DNV98

Chinese Brand Excavators:

Lonking: 6085, 200

Liugong: 60, 205, 220, 906, 907, 908, 920, 925, 936, CLG906C, CLG922LG

Yuchai: YC50-8, YC60-8, YC60-8, YC135-8, YC230, YC230-8, YC230LC-8, YC360, YC85, YC50, YC85-7, YC60-7, YC135

Sunward: 50, 60, 70, 150

Foton: FR85-7, FR65, FR80, FR150-7,

Zoomlion: 60, 205, 230, 360

Sany: SY55, SY60, SY215, SY230, SY210, SY220, SY310

XCMG: 60, 150, 700

Lovol: 210

The tire coupling has rubber or polyurethane aspects on the two hubs. When shearing, the rubber aspects transmit torque. Lowers transmission of shock masses or vibrations. Straightforward to assemble without having moving hubs or connecting gear, with substantial misalignment ability. Medium and high velocity procedure with broad torque variety

Consisting of two radially slotted hubs and a serpentine spring steel band, the mesh coupling provides the torsional damping and versatility of an elastomer, but with the energy of metal. Grid couplings transmit torque and change angular, parallel and axial misalignment from a single hub to one more by oscillating and sliding a tapered grid in the hub grooves. The mesh cross area is generally tapered for greater hub get in touch with and less difficult assembly. Lubrication is required thanks to the motion in between the get in touch with hub and the mesh metal parts.