Product Description

Product Description

Coupling Deatails

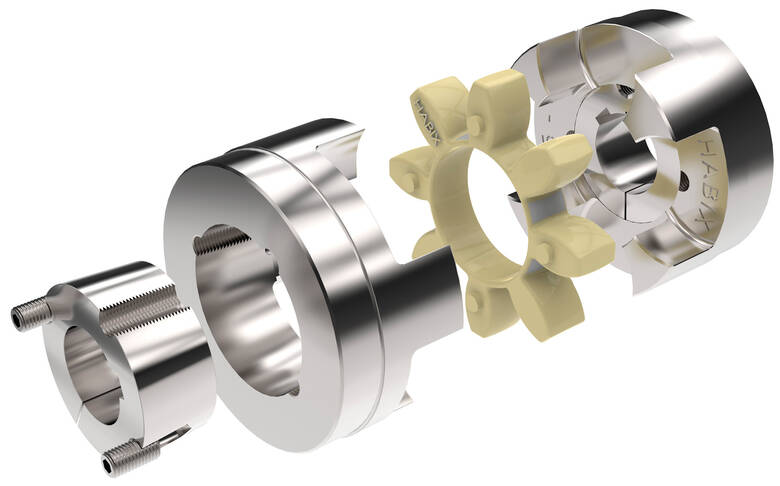

Name: High precision plum blossom

coupling Model: LM-Material: Aviation Aluminum Alloy

Working temperature: -40 ° C ~ 100 ° C

Support customization: Factory direct sales support customization.

Features:

1.Intermediate Elastomer Connection-Absorbs vibration, compensates for radial, angular, and axial 2.misalignment

3.Oil resistance and electrical insulation

4.Clockwise and counterclockwise rotation characteristics are identical-there are 3 different hardness 5.elastomer

6.Fixation by clamping screw.

|

Model parameter |

ΦD |

L |

LF |

LP |

F |

M |

Tightening screw torque |

|

(N.M) |

|||||||

|

GF-14X22 |

14 |

22 |

14.3 |

6.6 |

3.8 |

M 3 |

0.7 |

|

GF-20X25 |

20 |

25 |

16.7 |

8.6 |

4 |

M 3 |

0.7 |

|

GF-20X30 |

20 |

30 |

19.25 |

8.6 |

5.3 |

M 4 |

1.7 |

|

GF-25X30 |

25 |

30 |

20.82 |

11.6 |

5.6 |

M 4 |

1.7 |

|

GF-25X34 |

25 |

34 |

22.82 |

11.6 |

5.6 |

M 4 |

1.7 |

|

GF-30X35 |

30 |

35 |

23 |

11.5 |

5.75 |

M 4 |

1.7 |

|

GF-30X40 |

30 |

40 |

25.6 |

11.5 |

10 |

M 4 |

1.7 |

|

GF-40X50 |

40 |

50 |

32.1 |

14.5 |

10 |

M 5 |

4 |

|

GF-40X55 |

40 |

55 |

34.5 |

14.5 |

10 |

M 5 |

4 |

|

GF-40X66 |

40 |

66 |

40 |

14.5 |

12.75 |

M 5 |

4 |

|

GF-55X49 |

55 |

49 |

32 |

16.1 |

13.5 |

M 6 |

8.4 |

|

GF-55X78 |

55 |

78 |

46.4 |

16.1 |

15.5 |

M 6 |

8.4 |

|

GF-65X80 |

65 |

80 |

48.5 |

17.3 |

18.1 |

M 8 |

10.5 |

|

GF-65X90 |

65 |

90 |

53.5 |

17.3 |

18.1 |

M 8 |

10.5 |

Product Parameters

Detailed Photos

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Real-World Applications of Elastic Couplings

Elastic couplings find extensive use in various industries and applications where the reduction of vibration and shock is critical for performance, efficiency, and equipment longevity. Here are some examples:

- Industrial Machinery: Elastic couplings are commonly employed in industrial machinery such as pumps, compressors, conveyors, and generators. They help minimize vibration and shock, ensuring smooth and reliable operation while protecting sensitive components.

- Automotive Industry: In automotive applications, elastic couplings are used in drivetrains to dampen vibrations and shocks between the engine and the transmission. This enhances driving comfort, reduces noise, and prevents excessive wear on connected components.

- Power Generation: Power generation equipment, including turbines and generators, benefits from elastic couplings that absorb torsional vibrations and shocks. This aids in maintaining stable power output and extending the lifespan of critical components.

- Printing and Packaging: Printing presses and packaging machinery rely on elastic couplings to reduce vibrations during high-speed operations. This ensures precise printing and packaging while preventing damage to sensitive components.

- Robotics and Automation: Elastic couplings are crucial in robotics and automation systems to mitigate vibrations and shocks that can affect accuracy and reliability. They enable precise movement control and consistent performance.

- Medical Equipment: Medical devices such as MRI machines and X-ray equipment utilize elastic couplings to minimize vibrations that could impact image quality and precision during medical procedures.

These examples highlight how elastic couplings contribute to optimal performance, reduced maintenance, and increased equipment lifespan across diverse industries.

Maintaining the Longevity of Elastic Couplings

Ensuring the longevity and optimal performance of elastic couplings requires proper maintenance and care. Here are some key considerations:

- Regular Inspection: Periodically inspect the coupling for signs of wear, damage, or misalignment. Look for cracks, tears, or other deformations in the elastic elements.

- Lubrication: Some elastic couplings require lubrication for smooth operation. Follow the manufacturer’s guidelines on lubrication intervals and recommended lubricants.

- Environmental Conditions: Consider the operating environment of the coupling. Extreme temperatures, chemicals, moisture, and other factors can affect the coupling’s lifespan. Choose materials and designs suitable for the specific conditions.

- Proper Alignment: Ensure that the connected components are properly aligned to minimize excessive stress on the coupling. Misalignment can accelerate wear and reduce performance.

- Load Capacity: Do not exceed the coupling’s recommended torque and load ratings. Overloading the coupling can lead to premature failure.

- Shock and Vibration: If the system experiences frequent shock or vibration, consider using dampening or vibration-absorbing components to reduce the stress on the coupling.

- Replacement: When signs of wear or damage become noticeable, promptly replace the coupling to avoid further issues. Delaying replacement can lead to more significant problems in the machinery system.

- Follow Manufacturer Guidelines: Always follow the manufacturer’s recommendations for installation, operation, and maintenance of the specific coupling model.

By adhering to these considerations and performing regular maintenance tasks, engineers can extend the lifespan of elastic couplings and ensure reliable and efficient operation in various machinery applications.

Difference Between Elastic Coupling and Rigid Coupling

Elastic couplings and rigid couplings are two distinct types of couplings used in mechanical designs:

Elastic Coupling: An elastic coupling incorporates an elastomeric material, such as rubber, to provide flexibility and absorb shock and vibration. It allows for misalignment compensation and is ideal for applications where there may be slight misalignment or the need for vibration damping. Elastic couplings are commonly used in machinery that requires smooth operation and reduced stress on connected components.

Rigid Coupling: A rigid coupling, as the name suggests, is designed to provide a solid connection between two shafts. It does not have any flexible or damping elements and is used when precise alignment and torque transmission are critical. Rigid couplings are often used in applications where shafts need to maintain a constant alignment, such as in precision machines and systems with high torque requirements.

The choice between an elastic coupling and a rigid coupling depends on the specific requirements of the mechanical system, including the degree of misalignment, vibration levels, torque transmission, and the overall performance objectives.

editor by CX 2024-05-15

China best High Quality High Precision Ml Elastic Flexible Curved Jaw Rubber Spiders Shaft Coupling for Pump

Product Description

High Quality High Precision ml elastic Flexible curved jaw rubber spiders shaft coupling For Pump

Description:

A jaw coupling is a type of general purpose power transmission coupling that also can be used in motion control (servo) applications. It is designed to transmit torque (by connecting 2 shafts) while damping system vibrations and accommodating misalignment, which protects other components from damage. Jaw couplings are composed of 3 parts: 2 metallic hubs and an elastomer insert called an element, but commonly referred to as a “spider”. The 3 parts press fit together with a jaw from each hub fitted alternately with the lobes of the spider. Jaw coupling torque is transmitted through the elastomer lobes in compression.

The elastomer of the spider can be made in different materials and hardness, which allows the user to customize the coupling to best serve their application. Considerations for elastomer selection include ability to dampen vibration, ability to handle misalignment, operational temperature range, speed of equipment, and chemical conditions.

Features:

1.For heavy machinery;

2.Easy assblemly;

3.Cut off power when installation;

4.Can replace elastomer/spider withour moving driving and driven equipment.

Parameters:

Characteristics:

Flower-shaped elastic coupling has simple structure, small radial size, light weight and small moment of inertia. In medium and high speed applications, the plum-shaped elastic coupling works stably and reliably, and has good vibration damping, cushioning and electrical insulation properties. Plum-shaped elastic coupling has large axial, radial and angular compensation ability. High-strength polyurethane elastic components of plum-shaped elastic coupling are wear-resistant and oil-resistant, with large bearing capacity, long service life, safe and reliable, and coupling. No lubrication, no maintenance, continuous operation for a long time.

Plum-shaped flexible couplings are mainly suitable for starting, frequent reversing, medium and high speed, medium torque and high reliability requirements, such as metallurgy, mining, petroleum, chemical, lifting, transportation, light industry, textile, Pumps, fans, etc. Working environment temperature -35 ° C ~ +80 ° C, the transmission of nominal torque 25 ~ 12500Nm, the allowable speed of 1500 ~ 15300r / min.

Packing & shipping:

1 Prevent from damage.

2. As customers’ requirements, in perfect condition.

3. Delivery : As per contract delivery on time

4. Shipping : As per client request. We can accept CIF, Door to Door etc. or client authorized agent we supply all the necessary assistant.

FAQ:

Q 1: Are you a trading company or a manufacturer?

A: We are a professional manufacturer specializing in manufacturing various series of couplings.

Q 2:Can you do OEM?

Yes, we can. We can do OEM & ODM for all the customers with customized artworks in PDF or AI format.

Q 3:How long is your delivery time?

Generally, it is 20-30 days if the goods are not in stock. It is according to quantity.

Q 4: How long is your warranty?

A: Our Warranty is 12 months under normal circumstances.

Q 5: Do you have inspection procedures for coupling?

A:100% self-inspection before packing.

Q 6: Can I have a visit to your factory before the order?

A: Sure, welcome to visit our factory.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Compensation for Misalignment in Elastic Couplings

Elastic couplings are designed to accommodate certain degrees of misalignment between connected components in mechanical systems. The elastomeric material used in the coupling plays a crucial role in this compensation process:

When the two components connected by the elastic coupling experience angular, parallel, or axial misalignment, the elastomeric material deforms to a certain extent. This deformation allows the coupling to maintain its connection while absorbing the misalignment-induced stresses and forces.

The elastomer acts as a flexible link between the components, allowing them to move relative to each other within specified limits. The deformation of the elastomer also helps distribute the load more evenly, reducing stress concentrations and the risk of premature wear or damage to the coupling or connected components.

Elastic couplings can compensate for both static and dynamic misalignment, making them suitable for applications where minor misalignment is unavoidable due to factors such as manufacturing tolerances, thermal expansion, or vibration.

It’s important to note that while elastic couplings can accommodate misalignment, excessive misalignment should still be avoided, as it can lead to accelerated wear and reduced coupling lifespan. Regular inspection and maintenance are recommended to ensure that the coupling is operating within its designed limits.

Alternatives to Elastic Couplings for Flexible Connections in Machinery

There are several alternatives to elastic couplings for achieving flexible connections in machinery:

1. Universal Joints: Universal joints, also known as U-joints, are mechanical devices that allow rotational motion between two shafts at different angles. They are suitable for applications with significant misalignment.

2. Cardan Shafts: Cardan shafts consist of a series of universal joints connected in a line, allowing for the transmission of torque and rotation in complex systems.

3. Oldham Couplings: Oldham couplings use sliding disks to transmit torque while accommodating small misalignments. They are suitable for applications where precise positioning is required.

4. Beam Couplings: Beam couplings use a flexible beam to transmit torque and compensate for angular and axial misalignment.

5. Diaphragm Couplings: Diaphragm couplings use thin diaphragms to transmit torque while compensating for misalignment. They are often used in high-performance applications.

6. Gear Couplings: Gear couplings use teethed gears to transmit torque and accommodate misalignment. They are suitable for heavy-duty applications.

7. Chain Couplings: Chain couplings use roller chains to transmit torque and handle misalignment. They are commonly used in low-speed, high-torque applications.

8. Bellows Couplings: Bellows couplings use a bellows-like flexible element to transmit torque while compensating for misalignment.

Each of these alternatives has its own advantages and limitations, and the choice depends on the specific requirements of the application.

Principles of Torsionally Elastic Couplings

Torsionally elastic couplings, also known as flexible couplings, operate based on the principles of flexibility and torsional elasticity. These couplings are designed to transmit torque while accommodating misalignments, dampening vibrations, and providing protection against shock loads. Here’s how they work:

- Flexibility: Torsionally elastic couplings are made of materials that can flex or bend to some degree. This flexibility allows them to absorb misalignments between connected shafts, such as angular, parallel, and axial misalignments.

- Torsional Elasticity: The material properties of the coupling allow it to twist or deform slightly under torque loads. When torque is applied to one end of the coupling, the coupling flexes and twists to transmit torque to the other end while compensating for any misalignments.

- Vibration Dampening: The torsional elasticity of the coupling helps dampen vibrations that occur due to sudden torque changes or variations in load. This is especially important in applications where smooth operation and reduced vibrations are essential.

- Shock Load Protection: Torsionally elastic couplings can absorb and mitigate shock loads that might occur during sudden starts, stops, or changes in load. This protection prevents damage to connected equipment and extends the lifespan of machinery.

Overall, torsionally elastic couplings enhance the performance, reliability, and durability of machinery by providing flexibility, dampening vibrations, and protecting against misalignments and shock loads.

editor by CX 2024-05-09

China supplier CNC Aluminum Elastic Rubber Spider Jaw Shaft Coupler GF14*22 20*25 25*30 40*50 Shaft Flexible Coupling Ball Screw Plum Coupling

Product Description

Product Description

Coupling Deatails

Name: High precision plum blossom

coupling Model: LM-Material: Aviation Aluminum Alloy

Working temperature: -40 ° C ~ 100 ° C

Support customization: Factory direct sales support customization.

Features:

1.Intermediate Elastomer Connection-Absorbs vibration, compensates for radial, angular, and axial 2.misalignment

3.Oil resistance and electrical insulation

4.Clockwise and counterclockwise rotation characteristics are identical-there are 3 different hardness 5.elastomer

6.Fixation by clamping screw.

|

Model parameter |

ΦD |

L |

LF |

LP |

F |

M |

Tightening screw torque |

|

(N.M) |

|||||||

|

GF-14X22 |

14 |

22 |

14.3 |

6.6 |

3.8 |

M 3 |

0.7 |

|

GF-20X25 |

20 |

25 |

16.7 |

8.6 |

4 |

M 3 |

0.7 |

|

GF-20X30 |

20 |

30 |

19.25 |

8.6 |

5.3 |

M 4 |

1.7 |

|

GF-25X30 |

25 |

30 |

20.82 |

11.6 |

5.6 |

M 4 |

1.7 |

|

GF-25X34 |

25 |

34 |

22.82 |

11.6 |

5.6 |

M 4 |

1.7 |

|

GF-30X35 |

30 |

35 |

23 |

11.5 |

5.75 |

M 4 |

1.7 |

|

GF-30X40 |

30 |

40 |

25.6 |

11.5 |

10 |

M 4 |

1.7 |

|

GF-40X50 |

40 |

50 |

32.1 |

14.5 |

10 |

M 5 |

4 |

|

GF-40X55 |

40 |

55 |

34.5 |

14.5 |

10 |

M 5 |

4 |

|

GF-40X66 |

40 |

66 |

40 |

14.5 |

12.75 |

M 5 |

4 |

|

GF-55X49 |

55 |

49 |

32 |

16.1 |

13.5 |

M 6 |

8.4 |

|

GF-55X78 |

55 |

78 |

46.4 |

16.1 |

15.5 |

M 6 |

8.4 |

|

GF-65X80 |

65 |

80 |

48.5 |

17.3 |

18.1 |

M 8 |

10.5 |

|

GF-65X90 |

65 |

90 |

53.5 |

17.3 |

18.1 |

M 8 |

10.5 |

Product Parameters

Detailed Photos

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Reducing Vibration and Shock in Machinery with Elastic Couplings

Elastic couplings play a crucial role in minimizing vibration and shock in machinery by offering flexibility and damping characteristics. Here’s how they contribute to this important function:

- Vibration Absorption: Elastic couplings are designed with flexible elements that can absorb and dampen vibrations generated by rotating machinery. These flexible elements act as shock absorbers, reducing the transmission of vibrations to other parts of the system.

- Isolation: The inherent flexibility of elastic couplings isolates vibrations and shocks from one side of the coupling to the other. This prevents vibrations from propagating throughout the connected components, helping to protect sensitive equipment and improve overall system performance.

- Resonance Damping: Elastic couplings can help dampen resonance frequencies that can occur in machinery during operation. By absorbing and dissipating energy, they reduce the risk of resonance-related issues that can lead to mechanical failure or decreased efficiency.

- Smooth Torque Transmission: Elastic couplings offer a smooth torque transmission that helps reduce sudden torque spikes and shocks during start-up or sudden load changes. This prevents abrupt mechanical stresses that can lead to vibration and shock propagation.

- Increased Equipment Lifespan: By minimizing the impact of vibrations and shocks, elastic couplings contribute to the longevity of connected machinery and components. Reduced vibration-related wear and tear can extend the service life of the entire system.

Overall, elastic couplings are effective tools for managing vibration and shock in machinery, enhancing operational reliability, reducing maintenance needs, and maintaining optimal performance.

Installation Guidelines for Integrating Elastic Couplings

Proper installation of elastic couplings is essential to ensure their optimal performance and longevity. Engineers should follow these guidelines:

1. Alignment: Before installation, ensure that the connected shafts are properly aligned within the manufacturer’s specified tolerances. Misalignment can lead to premature wear and reduced coupling effectiveness.

2. Lubrication: Some elastic couplings require lubrication to maintain smooth operation. Follow the manufacturer’s recommendations for the type and amount of lubricant to use.

3. Mounting: Securely mount the elastic coupling onto the shafts using appropriate torque values for the coupling’s fasteners. Use a torque wrench to prevent over-tightening, which can damage the coupling or the shafts.

4. Inspection: Inspect the coupling for any signs of damage or defects before installation. Any issues should be addressed before the coupling is put into operation.

5. Clearance: Maintain proper clearance between the coupling and surrounding components to prevent interference during operation, especially if the coupling flexes during use.

6. Environmental Factors: Consider the operating environment, such as temperature, humidity, and exposure to chemicals, when selecting an appropriate elastic coupling material.

7. Manufacturer’s Recommendations: Always refer to the manufacturer’s installation guidelines and instructions specific to the type and model of elastic coupling being used.

Following these installation guidelines will help ensure the effective and safe integration of elastic couplings into mechanical systems.

Industries Using Elastic Couplings

Elastic couplings find extensive use in various industries due to their unique benefits:

- Industrial Manufacturing: Elastic couplings are widely used in manufacturing equipment, conveyors, and assembly lines to maintain smooth operation and reduce vibrations.

- Automotive: Automotive applications include engine components, powertrain systems, and vehicle suspension systems where flexibility and vibration dampening are crucial.

- Power Generation: Elastic couplings are used in power generation equipment such as generators, turbines, and pumps to absorb torsional vibrations and enhance efficiency.

- Aerospace: In aerospace applications, elastic couplings help dampen vibrations in critical components like aircraft engines and control systems.

- Renewable Energy: Wind turbines and solar tracking systems benefit from elastic couplings to accommodate misalignments and vibrations caused by changing wind conditions.

- Mining: Mining equipment such as crushers, conveyors, and screens utilize elastic couplings to handle varying loads and minimize shock loads.

- Marine: Elastic couplings are used in marine propulsion systems and ship equipment to manage torque fluctuations and reduce vibrations.

These industries rely on elastic couplings to enhance performance, extend machinery lifespan, and minimize downtime due to vibrations, misalignments, and shock loads.

editor by CX 2024-05-07

China Custom CFC Shaft Coupling PU Rubber Flexible Elastic Spiders Coupling Plum Shaft Couplings for Jaw Bush Shaft Coupler

Product Description

Excellent powder metallurgy parts metallic sintered parts

We could offer various powder metallurgy parts including iron based and copper based with top quality and cheapest price, please only send the drawing or sample to us, we will according to customer’s requirement to make it. if you are interested in our product, please do not hesitate to contact us, we would like to offer the top quality and best service for you. thank you!

How do We Work with Our Clients

1. For a design expert or a big company with your own engineering team: we prefer to receive a fully RFQ pack from you including drawing, 3D model, quantity, pictures;

2. For a start-up company owner or green hand for engineering: just send an idea that you want to try, you don’t even need to know what casting is;

3. Our sales will reply you within 24 hours to confirm further details and give the estimated quote time;

4. Our engineering team will evaluate your inquiry and provide our offer within next 1~3 working days.

5. We can arrange a technical communication meeting with you and our engineers together anytime if required.

| Place of origin: | Jangsu,China |

| Type: | Powder metallurgy sintering |

| Spare parts type: | Powder metallurgy parts |

| Machinery Test report: | Provided |

| Material: | Iron,stainless,steel,copper |

| Key selling points: | Quality assurance |

| Mould type: | Tungsten steel |

| Material standard: | MPIF 35,DIN 3571,JIS Z 2550 |

| Application: | Small home appliances,Lockset,Electric tool, automobile, |

| Brand Name: | OEM SERVICE |

| Plating: | Customized |

| After-sales Service: | Online support |

| Processing: | Powder Metallurgr,CNC Machining |

| Powder Metallurgr: | High frequency quenching, oil immersion |

| Quality Control: | 100% inspection |

The Advantage of Powder Metallurgy Process

1. Cost effective

The final products can be compacted with powder metallurgy method ,and no need or can shorten the processing of machine .It can save material greatly and reduce the production cost .

2. Complex shapes

Powder metallurgy allows to obtain complex shapes directly from the compacting tooling ,without any machining operation ,like teeth ,splines ,profiles ,frontal geometries etc.

3. High precision

Achievable tolerances in the perpendicular direction of compacting are typically IT 8-9 as sintered,improvable up to IT 5-7 after sizing .Additional machining operations can improve the precision .

4. Self-lubrication

The interconnected porosity of the material can be filled with oils ,obtaining then a self-lubricating bearing :the oil provides constant lubrication between bearing and shaft ,and the system does not need any additional external lubricant .

5. Green technology

The manufacturing process of sintered components is certified as ecological ,because the material waste is very low ,the product is recyclable ,and the energy efficiency is good because the material is not molten.

FAQ

Q1: What is the type of payment?

A: Usually you should prepay 50% of the total amount. The balance should be pay off before shipment.

Q2: How to guarantee the high quality?

A: 100% inspection. We have Carl Zeiss high-precision testing equipment and testing department to make sure every product of size,appearance and pressure test are good.

Q3: How long will you give me the reply?

A: we will contact you in 12 hours as soon as we can.

Q4. How about your delivery time?

A: Generally, it will take 25 to 35 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order. and if the item was non standard, we have to consider extra 10-15days for tooling/mould made.

Q5. Can you produce according to the samples or drawings?

A: Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

Q6: How about tooling Charge?

A: Tooling charge only charge once when first order, all future orders would not charge again even tooling repair or under maintance.

Q7: What is your sample policy?

A: We can supply the sample if we have ready parts in stock, but the customers have to pay the sample cost and the courier cost.

Q8: How do you make our business long-term and good relationship?

A: 1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Maintenance Requirements for Optimal Performance of Elastic Couplings

Maintaining elastic couplings is essential to ensure their optimal performance and longevity. Following these maintenance guidelines can help prevent premature wear and failure:

- Regular Inspection: Periodically inspect the coupling for signs of wear, such as cracks, deformities, or visible damage. This can help identify issues early and prevent further damage.

- Lubrication: Some elastic couplings require lubrication to reduce friction and wear. Follow the manufacturer’s recommendations for lubrication intervals and use compatible lubricants.

- Torque Check: Check the coupling’s torque values to ensure they are within the specified range. This helps maintain proper torque transmission and prevents overloading.

- Alignment Check: Monitor the alignment of the connected shafts regularly. Misalignment can cause excessive stress on the coupling, leading to premature failure.

- Vibration Analysis: Perform vibration analysis to identify any abnormal vibrations in the system. Excessive vibrations could indicate coupling or system issues that need attention.

- Temperature and Environment: Ensure that the coupling operates within the recommended temperature and environmental limits. Extreme conditions can affect the coupling’s material properties and performance.

- Coupling Wear: Keep track of the coupling’s wear over time. Depending on the application, the coupling might need replacement after a certain period of service.

- Expert Inspection: If any unusual symptoms or problems arise, consider having the coupling inspected by a qualified technician or engineer to diagnose the issue accurately.

Adhering to these maintenance practices helps extend the service life of elastic couplings, ensures reliable performance, and minimizes unexpected downtime and costly repairs.

Installation Guidelines for Integrating Elastic Couplings

Proper installation of elastic couplings is essential to ensure their optimal performance and longevity. Engineers should follow these guidelines:

1. Alignment: Before installation, ensure that the connected shafts are properly aligned within the manufacturer’s specified tolerances. Misalignment can lead to premature wear and reduced coupling effectiveness.

2. Lubrication: Some elastic couplings require lubrication to maintain smooth operation. Follow the manufacturer’s recommendations for the type and amount of lubricant to use.

3. Mounting: Securely mount the elastic coupling onto the shafts using appropriate torque values for the coupling’s fasteners. Use a torque wrench to prevent over-tightening, which can damage the coupling or the shafts.

4. Inspection: Inspect the coupling for any signs of damage or defects before installation. Any issues should be addressed before the coupling is put into operation.

5. Clearance: Maintain proper clearance between the coupling and surrounding components to prevent interference during operation, especially if the coupling flexes during use.

6. Environmental Factors: Consider the operating environment, such as temperature, humidity, and exposure to chemicals, when selecting an appropriate elastic coupling material.

7. Manufacturer’s Recommendations: Always refer to the manufacturer’s installation guidelines and instructions specific to the type and model of elastic coupling being used.

Following these installation guidelines will help ensure the effective and safe integration of elastic couplings into mechanical systems.

Elastic Coupling: Function and Working in Mechanical Systems

An elastic coupling is a type of coupling used in mechanical systems to connect two shafts and transmit torque while allowing for a certain degree of misalignment and flexibility. It consists of two hubs, each connected to a shaft, and an elastic element placed between the hubs.

The elastic element, often made of rubber or elastomer material, serves as a flexible medium that can absorb shocks, vibrations, and angular misalignments between the connected shafts. When torque is applied to one shaft, the elastic element deforms and compresses, allowing the coupling to transmit torque from one shaft to the other while compensating for minor misalignments.

As the elastic element absorbs vibrations and shocks, it helps reduce wear and tear on the connected machinery and enhances overall system efficiency. Elastic couplings are commonly used in applications where precise alignment between shafts is challenging or where vibration damping is crucial.

Overall, the elastic coupling’s design enables it to provide a balance between torque transmission and flexibility, making it a valuable component in various mechanical systems.

editor by CX 2024-04-30

China high quality Mh Elastomer Insert Elastic Jaw Flexible Shaft Coupling

Product Description

Product Description

COUPLINGS

| HRC | FCL | Chain coupling | GE | L | NM | MH | Torque limiter |

| HRC 70B | FCL90 | KC4012 | GE14 | L050 | NM50 | MH45 | TL250-2 |

| HRC 70F | FCL100 | KC4014 | GE19 | L070 | NM67 | MH55 | TL250-1 |

| HRC 70H | FCL112 | KC4016 | GE24 | L075 | NM82 | MH65 | TL350-2 |

| HRC 90B | FCL125 | KC5014 | GE28 | L090 | NM97 | MH80 | TL350-1 |

| HRC 90F | FCL140 | KC5016 | GE38 | L095 | NM112 | MH90 | TL500-2 |

| HRC 90H | FCL160 | KC6018 | GE42 | L099 | NM128 | MH115 | TL500-1 |

| HRC 110B | FCL180 | KC6571 | GE48 | L100 | NM148 | MH130 | TL700-2 |

| HRC 110F | FCL200 | KC6571 | GE55 | L110 | NM168 | MH145 | TL700-1 |

| HRC 110H | FCL224 | KC8018 | GE65 | L150 | NM194 | MH175 | |

| HRC 130B | FCL250 | KC8571 | GE75 | L190 | NM214 | MH200 | |

| HRC 130F | FCL280 | KC8571 | GE90 | L225 | |||

| HRC 130H | FCL315 | KC1571 | |||||

| HRC 150B | FCL355 | KC12018 | |||||

| HRC 150F | FCL400 | KC12571 | |||||

| HRC 150H | FCL450 | ||||||

| HRC 180B | FCL560 | ||||||

| HRC 180F | FCL630 | ||||||

| HRC 180H | |||||||

| HRC 230B | |||||||

| HRC 230F | |||||||

| HRC 230H | |||||||

| HRC 280B | |||||||

| HRC 280F | |||||||

| HRC 280H |

Catalogue

Workshop

Lots of couplings in stock

FAQ

Q1: Are you trading company or manufacturer ?

A: We are factory.

Q2: How long is your delivery time and shipment?

1.Sample Lead-times: 10-20 days.

2.Production Lead-times: 30-45 days after order confirmed.

Q3: What is your advantages?

1. The most competitive price and good quality.

2. Perfect technical engineers give you the best support.

3. OEM is available.

Real-World Applications of Elastic Couplings

Elastic couplings find extensive use in various industries and applications where the reduction of vibration and shock is critical for performance, efficiency, and equipment longevity. Here are some examples:

- Industrial Machinery: Elastic couplings are commonly employed in industrial machinery such as pumps, compressors, conveyors, and generators. They help minimize vibration and shock, ensuring smooth and reliable operation while protecting sensitive components.

- Automotive Industry: In automotive applications, elastic couplings are used in drivetrains to dampen vibrations and shocks between the engine and the transmission. This enhances driving comfort, reduces noise, and prevents excessive wear on connected components.

- Power Generation: Power generation equipment, including turbines and generators, benefits from elastic couplings that absorb torsional vibrations and shocks. This aids in maintaining stable power output and extending the lifespan of critical components.

- Printing and Packaging: Printing presses and packaging machinery rely on elastic couplings to reduce vibrations during high-speed operations. This ensures precise printing and packaging while preventing damage to sensitive components.

- Robotics and Automation: Elastic couplings are crucial in robotics and automation systems to mitigate vibrations and shocks that can affect accuracy and reliability. They enable precise movement control and consistent performance.

- Medical Equipment: Medical devices such as MRI machines and X-ray equipment utilize elastic couplings to minimize vibrations that could impact image quality and precision during medical procedures.

These examples highlight how elastic couplings contribute to optimal performance, reduced maintenance, and increased equipment lifespan across diverse industries.

Impact of Temperature Variations on Elastic Coupling Performance

Elastic couplings can be sensitive to temperature variations, and their performance can be influenced by both high and low temperatures:

1. High Temperatures: Elevated temperatures can cause the elastomeric material used in elastic couplings to soften, leading to a decrease in its mechanical properties. This can result in reduced torsional stiffness, damping capabilities, and overall coupling performance. High temperatures can also accelerate the aging process of the elastomer, leading to a shorter lifespan of the coupling. Additionally, excessive heat can cause thermal expansion of the coupling’s components, potentially leading to misalignment issues.

2. Low Temperatures: Extremely low temperatures can cause the elastomeric material to become more rigid, reducing its flexibility and damping characteristics. This can result in increased transmission of vibrations and shocks between connected components. Cold temperatures can also make the elastomer more brittle, increasing the risk of cracking or rupturing under mechanical stress.

It’s important to select an elastic coupling material that is suitable for the anticipated temperature range of the application. Some elastomers are formulated to perform well across a wide temperature range, while others are better suited for specific temperature conditions. Regular maintenance and inspection of elastic couplings in extreme temperature environments are crucial to ensure that the coupling continues to function as intended.

Elastic Coupling: Function and Working in Mechanical Systems

An elastic coupling is a type of coupling used in mechanical systems to connect two shafts and transmit torque while allowing for a certain degree of misalignment and flexibility. It consists of two hubs, each connected to a shaft, and an elastic element placed between the hubs.

The elastic element, often made of rubber or elastomer material, serves as a flexible medium that can absorb shocks, vibrations, and angular misalignments between the connected shafts. When torque is applied to one shaft, the elastic element deforms and compresses, allowing the coupling to transmit torque from one shaft to the other while compensating for minor misalignments.

As the elastic element absorbs vibrations and shocks, it helps reduce wear and tear on the connected machinery and enhances overall system efficiency. Elastic couplings are commonly used in applications where precise alignment between shafts is challenging or where vibration damping is crucial.

Overall, the elastic coupling’s design enables it to provide a balance between torque transmission and flexibility, making it a valuable component in various mechanical systems.

editor by CX 2023-09-06

China Hot selling CE ISO Approved Cast Iron Nm CZPT Compressor Motor Hydraulic Pump Connector Flexible Jaw Elastomer Elastic HRC Spider Rubber Rigid Shaft Coupling with Flange

Product Description

CE ISO Approved Cast Iron NM CZPT Compressor Motor Hydraulic Pump Connector Flexible Jaw Elastomer HRC Spider Rubber Rigid Shaft Coupling with Flange

Product Description

NM flexible shaft coupling is a cylindrical pin made of some non-metallic materials, which is placed between the 2 sides of the coupling and the inner surface of the outer ring, and a device to transfer the torque through the column pin to realize the connection between 2 half couplings. NM flexible shaft coupling between the slider made of bakelite cloth or polyurethane, suitable for high speed, large torque, no sharp impact of the 2 connections.

Product brand: EVER-POWER

Name of transmission part: water pump coupling

Product structure: it is composed of 2 cast iron claws and a natural rubber inner ring

Suitable shaft diameter: 7mm-75mm

Suitable motor power: within 60hp / 45KW

Product features:

1. The maximum torque is 125kgm 2. Stable operation and low noise 3. The product is made of cast iron and cast by precision die casting, so it is not easy to cause fracture during operation

Product introduction

NM elastic claw coupling is also called claw coupling. The structure is similar to the elastic plum CZPT coupling, which is made of specially designed synthetic rubber. The coupling consists of 2 cast iron (FC25 material) bodies and rubber. It is a connecting part between the pump and the motor, and is often used in general machinery.

Product features

It is economical, practical, quiet and stable, easy to assemble and maintain, and can provide high torque and intermittent operation for equipment. The coupling body is made of high-grade cast iron, and the rubber is made of NBR, which has excellent oil resistance, performance and TM; ACM is equivalent to fluororubber, and its working temperature is – 40~+120 ºC.

Product application

NM elastic coupling is widely used in supporting equipment of machinery industry, such as ceramic machinery, chemical machinery, woodworking machinery, plastic machinery, textile machinery, construction machinery, stainless steel machinery, auto parts industry, mechanical transmission, motor equipment, and paper products machinery industry.

Related products:

Company Profile

Ever power is a modern enterprise integrating research and development, design, manufacturing, sales and service. The company is a professional manufacturer of equipment integrating hydraulic transmission and mechanical transmission, providing multiple series of power transmission system solutions. The revolutionary innovation of our company – hub hydraulic connection technology is leading a product revolution that requires hub connection, such as expanding sleeve, coupling, bearing, etc., because of its compact structure, rapid installation, easy positioning, small runout, no damage to the joint surface and easy disassembly and assembly. The main products are hydraulic expansion sleeves, hydraulic coil spring couplings, hydraulic drum gear couplings, and various mechanical couplings. The company’s products are oriented to the global mining, chemical, steel, power, cement, metallurgy, port machinery, shipping, paper making, special pump industry and other fields. Adhering to the enterprise development concept of “people-oriented” and the quality policy of “excellence, endless, dedicated service and customer satisfaction”, the company is constantly moving towards the direction of globalization, modernization, youth and standardization of enterprise development!

Compensation for Misalignment in Elastic Couplings

Elastic couplings are designed to accommodate certain degrees of misalignment between connected components in mechanical systems. The elastomeric material used in the coupling plays a crucial role in this compensation process:

When the two components connected by the elastic coupling experience angular, parallel, or axial misalignment, the elastomeric material deforms to a certain extent. This deformation allows the coupling to maintain its connection while absorbing the misalignment-induced stresses and forces.

The elastomer acts as a flexible link between the components, allowing them to move relative to each other within specified limits. The deformation of the elastomer also helps distribute the load more evenly, reducing stress concentrations and the risk of premature wear or damage to the coupling or connected components.

Elastic couplings can compensate for both static and dynamic misalignment, making them suitable for applications where minor misalignment is unavoidable due to factors such as manufacturing tolerances, thermal expansion, or vibration.

It’s important to note that while elastic couplings can accommodate misalignment, excessive misalignment should still be avoided, as it can lead to accelerated wear and reduced coupling lifespan. Regular inspection and maintenance are recommended to ensure that the coupling is operating within its designed limits.

Installation Guidelines for Integrating Elastic Couplings

Proper installation of elastic couplings is essential to ensure their optimal performance and longevity. Engineers should follow these guidelines:

1. Alignment: Before installation, ensure that the connected shafts are properly aligned within the manufacturer’s specified tolerances. Misalignment can lead to premature wear and reduced coupling effectiveness.

2. Lubrication: Some elastic couplings require lubrication to maintain smooth operation. Follow the manufacturer’s recommendations for the type and amount of lubricant to use.

3. Mounting: Securely mount the elastic coupling onto the shafts using appropriate torque values for the coupling’s fasteners. Use a torque wrench to prevent over-tightening, which can damage the coupling or the shafts.

4. Inspection: Inspect the coupling for any signs of damage or defects before installation. Any issues should be addressed before the coupling is put into operation.

5. Clearance: Maintain proper clearance between the coupling and surrounding components to prevent interference during operation, especially if the coupling flexes during use.

6. Environmental Factors: Consider the operating environment, such as temperature, humidity, and exposure to chemicals, when selecting an appropriate elastic coupling material.

7. Manufacturer’s Recommendations: Always refer to the manufacturer’s installation guidelines and instructions specific to the type and model of elastic coupling being used.

Following these installation guidelines will help ensure the effective and safe integration of elastic couplings into mechanical systems.

Benefits of Using Elastic Couplings in Industrial Machinery

Elastic couplings offer several advantages when used in industrial machinery:

- Misalignment Compensation: Elastic couplings can accommodate small angular, axial, and radial misalignments between connected shafts. This ability to compensate for misalignment helps prolong the life of machinery components and reduces the risk of premature wear.

- Vibration Damping: The elastic element in the coupling absorbs and dampens vibrations generated during operation. This feature improves the overall smoothness of machinery operation, reduces noise, and minimizes the transmission of vibrations to other parts of the system.

- Shock Absorption: Elastic couplings absorb sudden shocks or impacts that may occur during operation. By reducing the impact load on the connected components, the coupling helps prevent damage and extends the lifespan of the machinery.

- Reduced Maintenance: The flexibility and shock-absorbing properties of elastic couplings contribute to lower maintenance requirements. Machinery components experience less stress and wear, resulting in longer intervals between maintenance tasks.

- Protection of Equipment: Elastic couplings act as a protective barrier between connected machinery. They isolate vibrations and shocks, preventing these forces from propagating throughout the system and potentially causing damage.

- Improved Efficiency: By minimizing misalignment-related losses and reducing vibrations, elastic couplings contribute to improved machinery efficiency. This can lead to energy savings and better overall performance.

In summary, elastic couplings play a crucial role in enhancing the reliability, longevity, and efficiency of industrial machinery by addressing misalignment, dampening vibrations, absorbing shocks, and minimizing maintenance needs.

editor by CX 2023-09-01

China Fl Jaw Flexible Coupling Steel Low Noise Flexible Shaft Coupling For Gearbox coupling and decoupling

Relevant Industries: Machinery Restore Retailers

Composition: Disc

Adaptable or Rigid: Versatile

Standard or Nonstandard: Regular

Content: Metal

Colour: Green

Crucial Phrase: FL jaw flexible coupling

Packaging Details: inner pack: use plastic bag and foam box for FL jaw adaptable coupling. outer pack: carton or picket scenario for each established or based on customer’s ask for.

Port: HangZhou or ZheJiang

1.Housing:Aluminium Alloy2. reduced sounds(<50DB)3.Design:FCL4.Efficient and risk-free operating5.ISO9001,Manufacturing facility price tag,OEM6.Technologies Information:

| Type: | FL jaw flexible coupling |

| Model: | FCL |

| Size: | —630 |

| Color: | Blue/Silver Or On Consumer Ask for |

| Packing: | Carton and Wooden Circumstance |

| Warranty: | 1 Yr |

| Input Electrical power: | 0.06KW,.09KW |

| Usages: | Industrial Machine: Meals Stuff, Ceramics,CHEMICAL,Packing,Dyeing, Car Styling Carbon Fiber Shade Gear Change Handle Decoration Go over Trim For BMW G20 G28 G22 G23 G29 G01 G02 Interior Accessories Woodworking,Glass. |

Types of Couplings

A coupling is a device used to join two shafts together and transmit power. Its purpose is to join rotating equipment while permitting a degree of end movement and misalignment. There are many types of couplings, and it is important to choose the right one for your application. Here are a few examples of couplings.

Mechanical

The mechanical coupling is an important component in power transmission systems. These couplings come in various forms and can be used in different types of applications. They can be flexible or rigid and operate in compression or shear. In some cases, they are permanently attached to the shaft, while in other cases, they are removable for service.

The simplest type of mechanical coupling is the sleeve coupling. It consists of a cylindrical sleeve with an internal diameter equal to the diameter of the shafts. The sleeve is connected to the shafts by a key that restricts their relative motion and prevents slippage. A few sleeve couplings also have threaded holes to prevent axial movement. This type of coupling is typically used for medium to light-duty torque.

Another type of mechanical coupling is a jaw coupling. It is used in motion control and general low-power transmission applications. This type of coupling does not require lubrication and is capable of accommodating angular misalignment. Unlike other types of couplings, the jaw coupling uses two hubs with intermeshing jaws. The jaw coupling’s spider is typically made of copper alloys. In addition, it is suitable for shock and vibration loads.

Mechanical couplings can be made from a variety of materials. One popular choice is rubber. The material can be natural or chloroprene. These materials are flexible and can tolerate slight misalignment.

Electrical

Electrical coupling is the process in which a single electrical signal is transferred from a nerve cell to another. It occurs when electrical signals from two nerve cells interact with each other in a way similar to haptic transmission. This type of coupling can occur on its own or in combination with electrotonic coupling in gap junctions.

Electrical coupling is often associated with oscillatory behavior of neurons. The mechanism of electrical coupling is complex and is studied mathematically to understand its effect on oscillatory neuron networks. For example, electrical coupling can increase or decrease the frequency of an oscillator, depending on the state of the neuron coupled to it.

The site of coupling is usually the junction of opposing cell membranes. The cellular resistance and the coupling resistance are measured in voltage-clamp experiments. This type of coupling has a specific resistance of 100 O-cm. As a result, the coupling resistance varies with the frequency.

The authors of this study noted that electrotonic coupling depends on the ratio between the resistance of the nonjunctional membranes and the junctional membranes. The voltage attenuation technique helps reveal the differences in resistance and shunting through the intercellular medium. However, it is unclear whether electrotonic coupling is electrostatically mediated.

Electrical coupling has also been suggested to play a role in the intercellular transfer of information. There are many examples that support this theory. A message can be a distinct qualitative or quantitative signal, which results in a gradient in the cells. Although gap junctions are absent at many embryonic interaction sites, increasing evidence suggests a role in information transfer.

Flexible

When it comes to choosing the right Flexible Coupling, there are several factors that you should take into account. Among these factors is the backlash that can be caused by the movement of the coupling. The reason for this problem is the fact that couplings that do not have anti-fungal properties can be easily infected by mold. The best way to avoid this is to pay attention to the moisture content of the area where you are installing the coupling. By following these guidelines, you can ensure the best possible installation.

To ensure that you are getting the most out of your flexible couplings, you must consider their characteristics and how easy they are to install, assemble, and maintain. You should also look for elements that are field-replaceable. Another important factor is the coupling’s torsional rigidity. It should also be able to handle reactionary loads caused by misalignment.

Flexible couplings come in many different types. There are diaphragm and spiral couplings. These couplings allow for axial motion, angular misalignment, and parallel offset. They have one-piece construction and are made from stainless steel or aluminum. These couplings also offer high torsional stiffness, which is beneficial for applications requiring high torques.

Flexible couplings have several advantages over their rigid counterparts. They are designed to handle misalignments of up to seven degrees and 0.025 inches. These characteristics are important in motion control applications. Flexible couplings are also inexpensive, and they do not require maintenance.

Beam

A beam coupling is a type of mechanical coupling, usually one solid piece, that connects two mechanical parts. Its performance is largely determined by the material used. Typical materials include stainless steel, aluminum, Delrin, and titanium. The beam coupling is rated for different speeds and torques. The coupling should be selected according to the application. In addition to the material, the application should also consider the speed and torque of the system.

There are two main types of beam couplings. The first is the helical beam coupling, which has a continuous multi spiral cut. This type of coupling offers a high degree of flexibility and compensates for a high degree of misalignment. The second type of beam coupling is the helical shaft coupling, which has a low torsional stiffness, which makes it ideal for small torque applications.

Another type of beam coupling is the multiple beam design, which combines two beams. It allows for more tolerance in manufacturing and installation and protects expensive components from excessive bearing loads. It also helps keep beams shorter than a single beam coupling. This type of coupling also enables a higher torque capacity and torsional stiffness.

Beam couplings can be manufactured with different materials, including stainless steel and aluminum. The “A” series is available in aluminum and stainless steel and is ideal for general-purpose and light-duty applications. It is also economical and durable. This type of coupling can also be used with low torque pumps or encoder/resolver systems.

Pin & bush

The Pin & bush coupling is a versatile, general-purpose coupling with high tensile bolts and rubber bushes. It can tolerate a wide range of operating temperatures and is suitable for use in oil and water-resistance applications. Its unique design enables it to be used in either direction. In addition, it requires no lubrication.

The pin bush coupling is a fail-safe coupling with a long service life and is used for high-torque applications. It provides torsional flexibility and dampens shocks, making it a flexible coupling that protects equipment and reduces maintenance costs. Its hubs are forged from graded cast iron for strength and durability. Besides, the coupling’s elastomer elements reduce vibration and impact loads. It also accommodates a misalignment of up to 0.5 degrees.

Pin & bush couplings are a popular choice for a variety of different applications. This coupling features a protective flange design that protects the coupling flange from wear and tear. The coupling nut is secured to one flange, while a rubber or leather bush sits between the other flange. Its unique design makes it ideal for use in applications where misalignment is a small factor. The rubber bushing also helps absorb vibration and shock.

Mesh tooth

Mesh tooth couplings are used to transfer torque between two shafts and reduce backlash. However, mesh tooth couplings have some limitations. One disadvantage is the break-away friction factor in the axial direction. This problem is caused by the high contact force between the tooth and gear mesh. This can cause unpredictable forces on the shafts.

In this paper, we present a FEM model for mesh tooth coupling. We first validate the mesh density. To do so, we compute the bolt stress as a uniaxial tensile during the tightening process. We used different mesh sizes and mesh density to validate our results.

The mesh stiffness of gear pairs is influenced by lead crown relief and misalignment. For example, if one tooth is positioned too far in the axis, the mesh stiffness will be decreased. A misaligned gear pair will lose torque capacity. A mesh tooth coupling can be lubricated with oil.

An ideal mesh tooth coupling has no gaps between the teeth, which reduces the risk of uneven wear. The coupling’s quality exposed fasteners include SAE Grade 5 bolts. It also offers corrosion resistance. The couplings are compatible with industrial environments. They also eliminate the need for selective assembly in sleeve couplings.

editor by czh 2023-03-13

China Cnc Motor Jaw Shaft Coupler 4 566.3589.51012mm 5mm To 8mm Flexible Coupling Ds19x25mm Guide Beltlinear Actuator Belt capacitor coupling

Problem: New

Relevant Industries: Garment Outlets, Development functions

Bodyweight (KG): .2

Video outgoing-inspection: Provided

Equipment Take a look at Report: Supplied

Advertising and marketing Variety: Normal Product

Warranty of core factors: 3 a long time

Main Factors: PLC, Motor, Bearing, Gearbox, Motor, Strain vessel, Equipment, Pump

Content: Customers’ Requirement

Surface area therapy: Customer’s Ask for

Provider: OEM ODM Customized

Packaging Specifics: plastic bag,box,picket scenario

Port: ZheJiang

Specification

| Service | Sand blasting, polishing, Anodize, zinc/nickel/chrome/ plating,Electricity coating, passivation,Warmth remedy, and many others. |

| Sheet Steel Fabrication | |

| Laser Chopping Service | |

| Stamping Parts | |

| Contro Box | |

| Material | *Aluminum |

| *Stainless Steel, Steel | |

| *Brass | |

| *Copper | |

| *Plastic | |

| Surface therapy | Sandblasting, Anodizing Coloration, Blackenning, Customized Alloy Steel Splined Gap Spur Chamfering Equipment for Gearbox of Transplanter ZincNickl Plating, Sharpening And Brushing,Etc. |

| MOQ | Quantity is not minimal, small buy can be approved |

| Drawing Structure | STEP, CAD, STP, DWG, DXF, PDF, Gis, and so on Or Samples |

| Delivery Time | 5-twenty five Times, Relies upon on the portions |

| Tolerance | +/- .01mm |

| QC | 100% Inspection prior to cargo |

| OEM&ODM | We can layout for you or creation merchandise same as your drawing |

| 3X3 | 4X4 | 5X5 | 6X6 | 6.35X6.35 | 8X8 | 10X10 |

| 3X4 | 4X5 | 5X6 | 6X6.35 | 6.35X8 | 8X10 | |

| 3X5 | 4X6 | 5X6.35 | 6X7 | 6.35X410 | ||

| 3X6.35 | 4X6.35 | 5X8 | 6X8 | |||

| 3X8 | 4X8 | 5X10 | 6X10 | |||

| 4X10 |

Functions and Modifications of Couplings

A coupling is a mechanical device that connects two shafts and transmits power. Its main purpose is to join two rotating pieces of equipment together, and it can also be used to allow some end movement or misalignment. There are many different types of couplings, each serving a specific purpose.

Functions

Functions of coupling are useful tools to study the dynamical interaction of systems. These functions have a wide range of applications, ranging from electrochemical processes to climate processes. The research being conducted on these functions is highly interdisciplinary, and experts from different fields are contributing to this issue. As such, this issue will be of interest to scientists and engineers in many fields, including electrical engineering, physics, and mathematics.

To ensure the proper coupling of data, coupling software must perform many essential functions. These include time interpolation and timing, and data exchange between the appropriate nodes. It should also guarantee that the time step of each model is divisible by the data exchange interval. This will ensure that the data exchange occurs at the proper times.

In addition to transferring power, couplings are also used in machinery. In general, couplings are used to join two rotating pieces. However, they can also have other functions, including compensating for misalignment, dampening axial motion, and absorbing shock. These functions determine the coupling type required.

The coupling strength can also be varied. For example, the strength of the coupling can change from negative to positive. This can affect the mode splitting width. Additionally, coupling strength is affected by fabrication imperfections. The strength of coupling can be controlled with laser non-thermal oxidation and water micro-infiltration, but these methods have limitations and are not reversible. Thus, the precise control of coupling strength remains a major challenge.

Applications

Couplings transmit power from a driver to the driven piece of equipment. The driver can be an electric motor, steam turbine, gearbox, fan, or pump. A coupling is often the weak link in a pump assembly, but replacing it is less expensive than replacing a sheared shaft.

Coupling functions have wide applications, including biomedical and electrical engineering. In this book, we review some of the most important developments and applications of coupling functions in these fields. We also discuss the future of the field and the implications of these discoveries. This is a comprehensive review of recent advances in coupling functions, and will help guide future research.

Adaptable couplings are another type of coupling. They are made up of a male and female spline in a polymeric material. They can be mounted using traditional keys, keyways, or taper bushings. For applications that require reversal, however, keyless couplings are preferable. Consider your process speed, maximum load capacity, and torque when choosing an adaptable coupling.

Coupling reactions are also used to make pharmaceutical products. These chemical reactions usually involve the joining of two chemical species. In most cases, a metal catalyst is used. The Ullmann reaction, for instance, is an important example of a hetero-coupling reaction. This reaction involves an organic halide with an organometallic compound. The result is a compound with the general formula R-M-R. Another important coupling reaction involves the Suzuki coupling, which unites two chemical species.

In engineering, couplings are mechanical devices that connect two shafts. Couplings are important because they enable the power to be transmitted from one end to the other without allowing a shaft to separate during operation. They also reduce maintenance time. Proper selection, installation, and maintenance, will reduce the amount of time needed to repair a coupling.

Maintenance

Maintenance of couplings is an important part of the lifecycle of your equipment. It’s important to ensure proper alignment and lubrication to keep them running smoothly. Inspecting your equipment for signs of wear can help you identify problems before they cause downtime. For instance, improper alignment can lead to uneven wear of the coupling’s hubs and grids. It can also cause the coupling to bind when you rotate the shaft manually. Proper maintenance will extend the life of your coupling.

Couplings should be inspected frequently and thoroughly. Inspections should go beyond alignment checks to identify problems and recommend appropriate repairs or replacements. Proper lubrication is important to protect the coupling from damage and can be easily identified using thermography or vibration analysis. In addition to lubrication, a coupling that lacks lubrication may require gaskets or sealing rings.

Proper maintenance of couplings will extend the life of the coupling by minimizing the likelihood of breakdowns. Proper maintenance will help you save money and time on repairs. A well-maintained coupling can be a valuable asset for your equipment and can increase productivity. By following the recommendations provided by your manufacturer, you can make sure your equipment is operating at peak performance.

Proper alignment and maintenance are critical for flexible couplings. Proper coupling alignment will maximize the life of your equipment. If you have a poorly aligned coupling, it may cause other components to fail. In some cases, this could result in costly downtime and increased costs for the company.

Proper maintenance of couplings should be done regularly to minimize costs and prevent downtime. Performing periodic inspections and lubrication will help you keep your equipment in top working order. In addition to the alignment and lubrication, you should also inspect the inside components for wear and alignment issues. If your coupling’s lubrication is not sufficient, it may lead to hardening and cracking. In addition, it’s possible to develop leaks that could cause damage.

Modifications

The aim of this paper is to investigate the effects of coupling modifications. It shows that such modifications can adversely affect the performance of the coupling mechanism. Moreover, the modifications can be predicted using chemical physics methods. The results presented here are not exhaustive and further research is needed to understand the effects of such coupling modifications.

The modifications to coupling involve nonlinear structural modifications. Four examples of such modifications are presented. Each is illustrated with example applications. Then, the results are verified through experimental and simulated case studies. The proposed methods are applicable to large and complex structures. They are applicable to a variety of engineering systems, including nonlinear systems.

editor by czh 2023-02-24

China Backlash Free Aluminum Jaw Flexible Shaft Coupling plum elastic coupling coupling energy

Warranty: negotiation

Applicable Industries: Creating Substance Shops, Manufacturing Plant, Equipment Fix Shops, Foods & Beverage Factory, Retail, Printing Outlets, Construction works , Strength & Mining, Other

Tailored help: OEM, ODM, OBM

Framework: Jaw / Spider

Flexible or Rigid: Flexible

Regular or Nonstandard: Standard

Materials: Aluminium

Solution name: Plum Blossom Elastic Cushion

Variety: Adaptable Clamp Coupling

Diameter: 14mm

Duration: 22mm

Min Bore d1: 3mm

Max Bore d1: 6.35mm

Min Bore d2: 3mm

Max Bore d2: 6.35mm

Merchandise Characteristics Features1、Elastic plum-shaped adaptable coupling2、During transmission, it can realize zero backlash torque transmission torque underneath low torque state3、The elastic spacer is created of polyurethane, and the torque exceeds the conventional claw coupling by far more than 2 times4、Plum blossom elastomer can resist oil and electrical insulation, running temperature: -20℃~80℃5、Excellent elastic effect to absorb vibration, eccentricity and deflection6、If there are multiple deviations, the allowable benefit of a single deviation will be lowered Attributes

| Name | Plum star coupling |

| Material | Main body:Aluminum alloy Elastomer:Polyurethane |

| Specification | DΦ14L22 |

| Aperture | Support good gap:Φ3-6.35mm |

| Surface treatment | Natural colour anode |

| Customized provider | Support light-weight customization and symbol customization |

| Remarks | The default engraving model title and measurement of the item. If you need to have not engraving, please get in touch with the buyer services for responses |

What Is a Coupling?

A coupling is a device that connects two shafts together. It transmits power from one to the other and is used to join rotating equipment. It can also allow for some degree of misalignment and end movement. It is used in mechanical engineering and manufacturing. To learn more about couplings, read this article. Mechanical connection between two objectsThe present invention relates to a method and assembly for forming a mechanical connection between two objects. The methods of this invention are suitable for connecting both solid and hollow objects. For example, the method can be used to make mechanical connections between two cylinders. This method is particularly useful for connecting two cylinders that are positioned near each other.

Mechanical connection between two objectsThe present invention relates to a method and assembly for forming a mechanical connection between two objects. The methods of this invention are suitable for connecting both solid and hollow objects. For example, the method can be used to make mechanical connections between two cylinders. This method is particularly useful for connecting two cylinders that are positioned near each other.

Absorbs vibration

A coupling insert is a part of a vehicle’s drivetrain that absorbs vibrations. These inserts are designed to prevent couplings from moving out of phase. However, the coupling inserts themselves can wear out and need to be replaced. Universal joints are an alternative if the coupling is out of phase by more than one degree. In addition, internal bearings in the coupling need to be lubricated and replaced when they begin to show signs of wear.

Another embodiment of the invention includes a flexible coupling 25 that includes rearwardly-extending lugs that extend toward the coupling member 23. These lugs interdigitate with corresponding lugs on the coupling member 23. They are spaced circumferentially. A first elastic member 28 is interposed between lugs 26 and 27, and is adapted to yield in a counterclockwise direction. As a result, it absorbs torsional vibrations.

Blocks heat transfer

Thermal coupling occurs when a solid block is thermally coupled to the air or fluid passing through it. The amount of heat transferred through a solid block depends on the heat transfer coefficients of the materials. This paper presents a numerical model to understand how heat transfers through different block materials. This work also describes the thermal resistance network for a one-dimensional block.

In some cases, thermal coupling increases the heat transfer mechanism. As illustrated in FIG. 1D, a heatpipe coupler 112 couples two heatpipes 110-1 and 110-2. This configuration allows the pipes to be coupled to the heat source and to the condenser. In addition, the heat pipe couplers may have bellows at the ends to help facilitate linear motion.

Thermal coupling is achieved by ensuring that at least one block is made of a material with a lower thermal expansion coefficient than the annulus. Ideally, the block’s mean thermal expansion coefficient is at least twenty percent lower than the annulus’s mean thermal expansion coefficient. This ensures that the thermal coupling between the two parts is as efficient as possible.

Another type of thermal coupling is achieved by using flexible elements. These are often washers or springs. These components allow the blocks to maintain physical contact with the post 55, which means that the heat transfer is more efficient even at higher temperatures. The flexibility of these elements also makes it possible to choose an element that will not impede assembly.

Protects rotating equipment

A reliable, long-lasting coupling system can reduce the risk of damage to rotating equipment. Designed to protect against torque overload and wear, Voith torque-limiting couplings provide outstanding safety and reliability. As a result, they can deliver maximum performance and minimize equipment downtime. In addition to their long-term benefits, these solutions are ideal for applications where safety and reliability are of paramount importance.

A good coupling provides many advantages, including the ability to transmit power, compensate for axial movement, and absorb shock. It is essential to choose the proper coupling for your application based on the basic conditions of your rotating equipment. For example, if you have two shafts with parallel rotation axes, you should choose a parallel coupling. Otherwise, you should use an angular coupling.

Torque-limiting couplings can also provide protection for rotating equipment by disengaging at a specific torque level. This protects the drive shaft from undergoing catastrophic failure. Torque limiters are particularly helpful for high-value equipment. By preventing catastrophic failure, you can avoid expensive repairs and minimize equipment downtime.

Coupling guards are easy to install and provide effective protection for rotating equipment. These covers are made of sheet metal bent to fit over the shaft. They are durable and easy to remove when necessary. This type of guard can prevent employees from catching their hands, tools, or loose clothing on motor coupling components.

editor by czh 2023-02-18

China Best Price Superior Quality Encounter Stepper Motor Flexible Jaw Shaft Coupling coupling and repulsion

Guarantee: 6 months

Applicable Industries: Manufacturing Plant, Equipment Fix Outlets, Printing Stores, Other, Advertising and marketing Business

Standard or Nonstandard: Common

Content: Aluminum, Aluminum

Merchandise Title: Spiral beam coupling

Surface concluded: Anodized

Dimension. (mm): O.D. 8 ~ 32

Repairing strategy: established screw correcting Clamping fixing

Allowable angular misalignment: .5~2*Verify spec. for information

Allowable torque: .1~8 *Check spec. for details.

MOQ: 1pcs

Product Variety: FAMMS

Application: Operate with sensor essential high overall performance

Packaging Specifics: paper box

Port: ZheJiang

Specification

| Applicable Industries | Manufacturing Plant, Machinery Mend Retailers, Printing Retailers, Other, Advertising and marketing Business |

| After Warranty Services | Video technical assist, Online assistance |

| Length | 8 ~ 40mm |

| Place of Origin | ZheJiang , China |

| Brand Identify | GMT |

| Product Name | Spiral beam coupling |

| Material | Aluminum |

| Surface completed | Anodized |

| Dimension. (mm) | O.D. 8 ~ forty |

| Fixing strategy | Set screw repairing Clamping fixing |

| Allowable angular misalignment | 0.5∘~ 2∘ *Verify spec. for specifics.C3/C5/C7 |

| Allowable parallel misalignment (mm) | 0.05 ~ .20 *Check spec. for details. |

| Allowable torque (N∙m) | 0.1 ~ 8 *Verify spec. for details. |

| Application | Work with sensor needed higher performance*Standard circumstance for reference only. Examine spec. for far more suggestions. |

| Moment of inertia (kg∙cm2) | 1.*ten-8 ~ 9.7*10-5*Verify spec. for specifics. |

Types of Couplings

A coupling is a device used to join two shafts together and transmit power. Its purpose is to join rotating equipment while permitting a degree of end movement and misalignment. There are many types of couplings, and it is important to choose the right one for your application. Here are a few examples of couplings.

Mechanical

The mechanical coupling is an important component in power transmission systems. These couplings come in various forms and can be used in different types of applications. They can be flexible or rigid and operate in compression or shear. In some cases, they are permanently attached to the shaft, while in other cases, they are removable for service.

The simplest type of mechanical coupling is the sleeve coupling. It consists of a cylindrical sleeve with an internal diameter equal to the diameter of the shafts. The sleeve is connected to the shafts by a key that restricts their relative motion and prevents slippage. A few sleeve couplings also have threaded holes to prevent axial movement. This type of coupling is typically used for medium to light-duty torque.

Another type of mechanical coupling is a jaw coupling. It is used in motion control and general low-power transmission applications. This type of coupling does not require lubrication and is capable of accommodating angular misalignment. Unlike other types of couplings, the jaw coupling uses two hubs with intermeshing jaws. The jaw coupling’s spider is typically made of copper alloys. In addition, it is suitable for shock and vibration loads.

Mechanical couplings can be made from a variety of materials. One popular choice is rubber. The material can be natural or chloroprene. These materials are flexible and can tolerate slight misalignment.

Electrical