Product Description

Product Description

Coupling Deatails

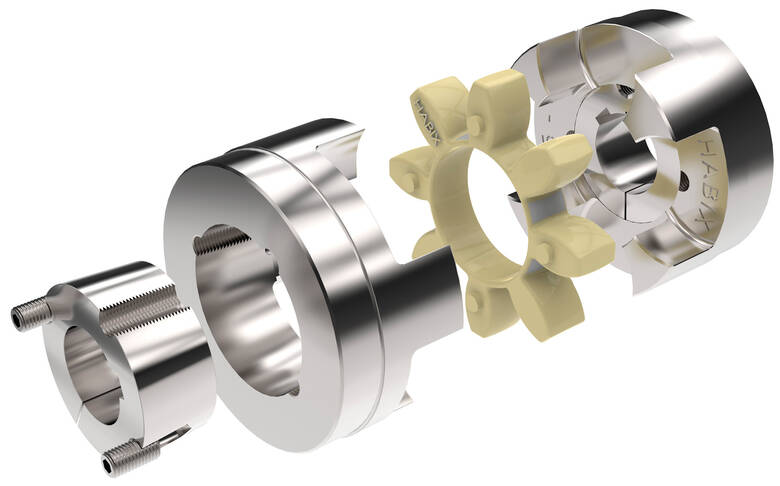

Name: High precision plum blossom

coupling Model: LM-Material: Aviation Aluminum Alloy

Working temperature: -40 ° C ~ 100 ° C

Support customization: Factory direct sales support customization.

Features:

1.Intermediate Elastomer Connection-Absorbs vibration, compensates for radial, angular, and axial 2.misalignment

3.Oil resistance and electrical insulation

4.Clockwise and counterclockwise rotation characteristics are identical-there are 3 different hardness 5.elastomer

6.Fixation by clamping screw.

|

Model parameter |

ΦD |

L |

LF |

LP |

F |

M |

Tightening screw torque |

|

(N.M) |

|||||||

|

GF-14X22 |

14 |

22 |

14.3 |

6.6 |

3.8 |

M 3 |

0.7 |

|

GF-20X25 |

20 |

25 |

16.7 |

8.6 |

4 |

M 3 |

0.7 |

|

GF-20X30 |

20 |

30 |

19.25 |

8.6 |

5.3 |

M 4 |

1.7 |

|

GF-25X30 |

25 |

30 |

20.82 |

11.6 |

5.6 |

M 4 |

1.7 |

|

GF-25X34 |

25 |

34 |

22.82 |

11.6 |

5.6 |

M 4 |

1.7 |

|

GF-30X35 |

30 |

35 |

23 |

11.5 |

5.75 |

M 4 |

1.7 |

|

GF-30X40 |

30 |

40 |

25.6 |

11.5 |

10 |

M 4 |

1.7 |

|

GF-40X50 |

40 |

50 |

32.1 |

14.5 |

10 |

M 5 |

4 |

|

GF-40X55 |

40 |

55 |

34.5 |

14.5 |

10 |

M 5 |

4 |

|

GF-40X66 |

40 |

66 |

40 |

14.5 |

12.75 |

M 5 |

4 |

|

GF-55X49 |

55 |

49 |

32 |

16.1 |

13.5 |

M 6 |

8.4 |

|

GF-55X78 |

55 |

78 |

46.4 |

16.1 |

15.5 |

M 6 |

8.4 |

|

GF-65X80 |

65 |

80 |

48.5 |

17.3 |

18.1 |

M 8 |

10.5 |

|

GF-65X90 |

65 |

90 |

53.5 |

17.3 |

18.1 |

M 8 |

10.5 |

Product Parameters

Detailed Photos

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Real-World Applications of Elastic Couplings

Elastic couplings find extensive use in various industries and applications where the reduction of vibration and shock is critical for performance, efficiency, and equipment longevity. Here are some examples:

- Industrial Machinery: Elastic couplings are commonly employed in industrial machinery such as pumps, compressors, conveyors, and generators. They help minimize vibration and shock, ensuring smooth and reliable operation while protecting sensitive components.

- Automotive Industry: In automotive applications, elastic couplings are used in drivetrains to dampen vibrations and shocks between the engine and the transmission. This enhances driving comfort, reduces noise, and prevents excessive wear on connected components.

- Power Generation: Power generation equipment, including turbines and generators, benefits from elastic couplings that absorb torsional vibrations and shocks. This aids in maintaining stable power output and extending the lifespan of critical components.

- Printing and Packaging: Printing presses and packaging machinery rely on elastic couplings to reduce vibrations during high-speed operations. This ensures precise printing and packaging while preventing damage to sensitive components.

- Robotics and Automation: Elastic couplings are crucial in robotics and automation systems to mitigate vibrations and shocks that can affect accuracy and reliability. They enable precise movement control and consistent performance.

- Medical Equipment: Medical devices such as MRI machines and X-ray equipment utilize elastic couplings to minimize vibrations that could impact image quality and precision during medical procedures.

These examples highlight how elastic couplings contribute to optimal performance, reduced maintenance, and increased equipment lifespan across diverse industries.

Maintaining the Longevity of Elastic Couplings

Ensuring the longevity and optimal performance of elastic couplings requires proper maintenance and care. Here are some key considerations:

- Regular Inspection: Periodically inspect the coupling for signs of wear, damage, or misalignment. Look for cracks, tears, or other deformations in the elastic elements.

- Lubrication: Some elastic couplings require lubrication for smooth operation. Follow the manufacturer’s guidelines on lubrication intervals and recommended lubricants.

- Environmental Conditions: Consider the operating environment of the coupling. Extreme temperatures, chemicals, moisture, and other factors can affect the coupling’s lifespan. Choose materials and designs suitable for the specific conditions.

- Proper Alignment: Ensure that the connected components are properly aligned to minimize excessive stress on the coupling. Misalignment can accelerate wear and reduce performance.

- Load Capacity: Do not exceed the coupling’s recommended torque and load ratings. Overloading the coupling can lead to premature failure.

- Shock and Vibration: If the system experiences frequent shock or vibration, consider using dampening or vibration-absorbing components to reduce the stress on the coupling.

- Replacement: When signs of wear or damage become noticeable, promptly replace the coupling to avoid further issues. Delaying replacement can lead to more significant problems in the machinery system.

- Follow Manufacturer Guidelines: Always follow the manufacturer’s recommendations for installation, operation, and maintenance of the specific coupling model.

By adhering to these considerations and performing regular maintenance tasks, engineers can extend the lifespan of elastic couplings and ensure reliable and efficient operation in various machinery applications.

Difference Between Elastic Coupling and Rigid Coupling

Elastic couplings and rigid couplings are two distinct types of couplings used in mechanical designs:

Elastic Coupling: An elastic coupling incorporates an elastomeric material, such as rubber, to provide flexibility and absorb shock and vibration. It allows for misalignment compensation and is ideal for applications where there may be slight misalignment or the need for vibration damping. Elastic couplings are commonly used in machinery that requires smooth operation and reduced stress on connected components.

Rigid Coupling: A rigid coupling, as the name suggests, is designed to provide a solid connection between two shafts. It does not have any flexible or damping elements and is used when precise alignment and torque transmission are critical. Rigid couplings are often used in applications where shafts need to maintain a constant alignment, such as in precision machines and systems with high torque requirements.

The choice between an elastic coupling and a rigid coupling depends on the specific requirements of the mechanical system, including the degree of misalignment, vibration levels, torque transmission, and the overall performance objectives.

editor by CX 2024-05-15

China supplier CNC Aluminum Elastic Rubber Spider Jaw Shaft Coupler GF14*22 20*25 25*30 40*50 Shaft Flexible Coupling Ball Screw Plum Coupling

Product Description

Product Description

Coupling Deatails

Name: High precision plum blossom

coupling Model: LM-Material: Aviation Aluminum Alloy

Working temperature: -40 ° C ~ 100 ° C

Support customization: Factory direct sales support customization.

Features:

1.Intermediate Elastomer Connection-Absorbs vibration, compensates for radial, angular, and axial 2.misalignment

3.Oil resistance and electrical insulation

4.Clockwise and counterclockwise rotation characteristics are identical-there are 3 different hardness 5.elastomer

6.Fixation by clamping screw.

|

Model parameter |

ΦD |

L |

LF |

LP |

F |

M |

Tightening screw torque |

|

(N.M) |

|||||||

|

GF-14X22 |

14 |

22 |

14.3 |

6.6 |

3.8 |

M 3 |

0.7 |

|

GF-20X25 |

20 |

25 |

16.7 |

8.6 |

4 |

M 3 |

0.7 |

|

GF-20X30 |

20 |

30 |

19.25 |

8.6 |

5.3 |

M 4 |

1.7 |

|

GF-25X30 |

25 |

30 |

20.82 |

11.6 |

5.6 |

M 4 |

1.7 |

|

GF-25X34 |

25 |

34 |

22.82 |

11.6 |

5.6 |

M 4 |

1.7 |

|

GF-30X35 |

30 |

35 |

23 |

11.5 |

5.75 |

M 4 |

1.7 |

|

GF-30X40 |

30 |

40 |

25.6 |

11.5 |

10 |

M 4 |

1.7 |

|

GF-40X50 |

40 |

50 |

32.1 |

14.5 |

10 |

M 5 |

4 |

|

GF-40X55 |

40 |

55 |

34.5 |

14.5 |

10 |

M 5 |

4 |

|

GF-40X66 |

40 |

66 |

40 |

14.5 |

12.75 |

M 5 |

4 |

|

GF-55X49 |

55 |

49 |

32 |

16.1 |

13.5 |

M 6 |

8.4 |

|

GF-55X78 |

55 |

78 |

46.4 |

16.1 |

15.5 |

M 6 |

8.4 |

|

GF-65X80 |

65 |

80 |

48.5 |

17.3 |

18.1 |

M 8 |

10.5 |

|

GF-65X90 |

65 |

90 |

53.5 |

17.3 |

18.1 |

M 8 |

10.5 |

Product Parameters

Detailed Photos

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Reducing Vibration and Shock in Machinery with Elastic Couplings

Elastic couplings play a crucial role in minimizing vibration and shock in machinery by offering flexibility and damping characteristics. Here’s how they contribute to this important function:

- Vibration Absorption: Elastic couplings are designed with flexible elements that can absorb and dampen vibrations generated by rotating machinery. These flexible elements act as shock absorbers, reducing the transmission of vibrations to other parts of the system.

- Isolation: The inherent flexibility of elastic couplings isolates vibrations and shocks from one side of the coupling to the other. This prevents vibrations from propagating throughout the connected components, helping to protect sensitive equipment and improve overall system performance.

- Resonance Damping: Elastic couplings can help dampen resonance frequencies that can occur in machinery during operation. By absorbing and dissipating energy, they reduce the risk of resonance-related issues that can lead to mechanical failure or decreased efficiency.

- Smooth Torque Transmission: Elastic couplings offer a smooth torque transmission that helps reduce sudden torque spikes and shocks during start-up or sudden load changes. This prevents abrupt mechanical stresses that can lead to vibration and shock propagation.

- Increased Equipment Lifespan: By minimizing the impact of vibrations and shocks, elastic couplings contribute to the longevity of connected machinery and components. Reduced vibration-related wear and tear can extend the service life of the entire system.

Overall, elastic couplings are effective tools for managing vibration and shock in machinery, enhancing operational reliability, reducing maintenance needs, and maintaining optimal performance.

Installation Guidelines for Integrating Elastic Couplings

Proper installation of elastic couplings is essential to ensure their optimal performance and longevity. Engineers should follow these guidelines:

1. Alignment: Before installation, ensure that the connected shafts are properly aligned within the manufacturer’s specified tolerances. Misalignment can lead to premature wear and reduced coupling effectiveness.

2. Lubrication: Some elastic couplings require lubrication to maintain smooth operation. Follow the manufacturer’s recommendations for the type and amount of lubricant to use.

3. Mounting: Securely mount the elastic coupling onto the shafts using appropriate torque values for the coupling’s fasteners. Use a torque wrench to prevent over-tightening, which can damage the coupling or the shafts.

4. Inspection: Inspect the coupling for any signs of damage or defects before installation. Any issues should be addressed before the coupling is put into operation.

5. Clearance: Maintain proper clearance between the coupling and surrounding components to prevent interference during operation, especially if the coupling flexes during use.

6. Environmental Factors: Consider the operating environment, such as temperature, humidity, and exposure to chemicals, when selecting an appropriate elastic coupling material.

7. Manufacturer’s Recommendations: Always refer to the manufacturer’s installation guidelines and instructions specific to the type and model of elastic coupling being used.

Following these installation guidelines will help ensure the effective and safe integration of elastic couplings into mechanical systems.

Industries Using Elastic Couplings

Elastic couplings find extensive use in various industries due to their unique benefits:

- Industrial Manufacturing: Elastic couplings are widely used in manufacturing equipment, conveyors, and assembly lines to maintain smooth operation and reduce vibrations.

- Automotive: Automotive applications include engine components, powertrain systems, and vehicle suspension systems where flexibility and vibration dampening are crucial.

- Power Generation: Elastic couplings are used in power generation equipment such as generators, turbines, and pumps to absorb torsional vibrations and enhance efficiency.

- Aerospace: In aerospace applications, elastic couplings help dampen vibrations in critical components like aircraft engines and control systems.

- Renewable Energy: Wind turbines and solar tracking systems benefit from elastic couplings to accommodate misalignments and vibrations caused by changing wind conditions.

- Mining: Mining equipment such as crushers, conveyors, and screens utilize elastic couplings to handle varying loads and minimize shock loads.

- Marine: Elastic couplings are used in marine propulsion systems and ship equipment to manage torque fluctuations and reduce vibrations.

These industries rely on elastic couplings to enhance performance, extend machinery lifespan, and minimize downtime due to vibrations, misalignments, and shock loads.

editor by CX 2024-05-07

China DEV01 YHD Good Quality Flexible Shaft Coupling Factory Price Economical Rigid Coupling for CNC Machine coupling beam

Relevant Industries: Resorts, Garment Retailers, Developing Material Retailers, Producing Plant, Machinery Fix Stores, Food & Beverage Manufacturing unit, Farms, Cafe, Property Use, Retail, Foods Store, Printing Stores, Construction works , Strength & Mining, Japanese Unique Gasoline Motor V8 3UZ 2UZ 1UZ Motor Assembly With Gearbox for CZPT Lexus 4.7L Meals & Beverage Retailers, Other, Promoting Company

Personalized help: OEM, ODM, OBM

Framework: Jaw / Spider

Flexible or Rigid: Rigid

Standard or Nonstandard: Regular

Material: Aluminium alloy

Product name: Versatile Couplings Coupler

Variety: screw fixing variety

Application: Shaft Connections

Surface Therapy: Pearl nickel plating

MOQ: 1 Pcs

Packing: Carton Box

High quality: 100%examined

Outer diameter: 19-82mm

Excess weight: .01-1kg

Internal gap diameter: 3-35mm

Packaging Information: carton packaging

Port: HangZhou

Vendor Recommend Video clip Demonstrate TIPS: DEV01 YHD Very good Good quality Flexible Shaft Coupling Manufacturing unit Price tag Cost-effective Rigid Coupling for CNC Machine1. Very crucial! You should refer to the desk beneath carefully to pick the specification of coupling bushing you want, Pleasecontact client services to affirm prior to positioning an order.2. We supply a detailed PDF sort for your reference. If essential, please contact buyer provider to deliver it to you.3. A lot more importantly, we also provide 3D versions, which can be imported into 3D software for immediate use. Every single model gives a variety of 3D and 2d structure graphics information, such as hundreds of formats these kinds of as Catia, Solidworks, IGS, Phase, Jetshark one thousand-7000 Collection Metal Spinning Reel 13bb 5.2 1 Gear Ratio 10kg Max Drag Light-weight Challenging Mini Spinning Fishing Reel DWG, and so forth., which is practical for you to use immediately when designing, eliminating the problems of drawing. If essential, please get in touch with consumer service.

| Product title | Flexible Couplings Coupler | ||||||

| Material | Aluminum alloy | ||||||

| Structure | Jaw / Spider | ||||||

| Surface Remedy | Pearl nickel plating | ||||||

| Flexible or Rigid | Flexible | ||||||

| Outer diameter | 19-82mm | ||||||

| Inner gap diameter | 3-35mm | ||||||

What Is a Coupling?

A coupling is a mechanical device that links two shafts together and transmits power. Its purpose is to join rotating equipment while permitting a small amount of misalignment or end movement. Couplings come in a variety of different types and are used in a variety of applications. They can be used in hydraulics, pneumatics, and many other industries.

Types

Coupling is a term used to describe a relationship between different modules. When a module depends on another, it can have different types of coupling. Common coupling occurs when modules share certain overall constraints. When this type of coupling occurs, any changes to the common constraint will also affect the other modules. Common coupling has its advantages and disadvantages. It is difficult to maintain and provides less control over the modules than other types of coupling.

There are many types of coupling, including meshing tooth couplings, pin and bush couplings, and spline couplings. It is important to choose the right coupling type for your specific application to get maximum uptime and long-term reliability. Listed below are the differences between these coupling types.

Rigid couplings have no flexibility, and require good alignment of the shafts and support bearings. They are often used in applications where high torque is required, such as in push-pull machines. These couplings are also useful in applications where the shafts are firmly attached to one another.

Another type of coupling is the split muff coupling. This type is made of cast iron and has two threaded holes. The coupling halves are attached with bolts or studs.

Applications

The coupling function is an incredibly versatile mathematical tool that can be used in many different scientific domains. These applications range from physics and mathematics to biology, chemistry, cardio-respiratory physiology, climate science, and electrical engineering. The coupling function can also help to predict the transition from one state to another, as well as describing the functional contributions of subsystems in the system. In some cases, it can even be used to reveal the mechanisms that underlie the functionality of interactions.

The coupling selection process begins with considering the intended use of the coupling. The application parameters must be determined, as well as the operating conditions. For example, if the coupling is required to be used for power transmission, the design engineer should consider how easily the coupling can be installed and serviced. This step is vital because improper installation can result in a more severe misalignment than is specified. Additionally, the coupling must be inspected regularly to ensure that the design parameters remain consistent and that no detrimental factors develop.

Choosing the right coupling for your application is an important process, but it need not be difficult. To find the right coupling, you must consider the type of machine and environment, as well as the torque, rpm, and inertia of the system. By answering these questions, you will be able to select the best coupling for your specific application.

Problems

A coupling is a device that connects two rotating shafts to transfer torque and rotary motion. To achieve optimal performance, a coupling must be designed for the application requirements it serves. These requirements include service, environmental, and use parameters. Otherwise, it can prematurely fail, causing inconvenience and financial loss.

In order to prevent premature failure, couplings should be properly installed and maintained. A good practice is to refer to the specifications provided by the manufacturer. Moreover, it is important to perform periodic tests to evaluate the effectiveness of the coupling. The testing of couplings should be performed by qualified personnel.

editor by czh 2023-03-05

China Cnc Motor Jaw Shaft Coupler 4 566.3589.51012mm 5mm To 8mm Flexible Coupling Ds19x25mm Guide Beltlinear Actuator Belt capacitor coupling

Problem: New

Relevant Industries: Garment Outlets, Development functions

Bodyweight (KG): .2

Video outgoing-inspection: Provided

Equipment Take a look at Report: Supplied

Advertising and marketing Variety: Normal Product

Warranty of core factors: 3 a long time

Main Factors: PLC, Motor, Bearing, Gearbox, Motor, Strain vessel, Equipment, Pump

Content: Customers’ Requirement

Surface area therapy: Customer’s Ask for

Provider: OEM ODM Customized

Packaging Specifics: plastic bag,box,picket scenario

Port: ZheJiang

Specification

| Service | Sand blasting, polishing, Anodize, zinc/nickel/chrome/ plating,Electricity coating, passivation,Warmth remedy, and many others. |

| Sheet Steel Fabrication | |

| Laser Chopping Service | |

| Stamping Parts | |

| Contro Box | |

| Material | *Aluminum |

| *Stainless Steel, Steel | |

| *Brass | |

| *Copper | |

| *Plastic | |

| Surface therapy | Sandblasting, Anodizing Coloration, Blackenning, Customized Alloy Steel Splined Gap Spur Chamfering Equipment for Gearbox of Transplanter ZincNickl Plating, Sharpening And Brushing,Etc. |

| MOQ | Quantity is not minimal, small buy can be approved |

| Drawing Structure | STEP, CAD, STP, DWG, DXF, PDF, Gis, and so on Or Samples |

| Delivery Time | 5-twenty five Times, Relies upon on the portions |

| Tolerance | +/- .01mm |

| QC | 100% Inspection prior to cargo |

| OEM&ODM | We can layout for you or creation merchandise same as your drawing |

| 3X3 | 4X4 | 5X5 | 6X6 | 6.35X6.35 | 8X8 | 10X10 |

| 3X4 | 4X5 | 5X6 | 6X6.35 | 6.35X8 | 8X10 | |

| 3X5 | 4X6 | 5X6.35 | 6X7 | 6.35X410 | ||

| 3X6.35 | 4X6.35 | 5X8 | 6X8 | |||

| 3X8 | 4X8 | 5X10 | 6X10 | |||

| 4X10 |

Functions and Modifications of Couplings

A coupling is a mechanical device that connects two shafts and transmits power. Its main purpose is to join two rotating pieces of equipment together, and it can also be used to allow some end movement or misalignment. There are many different types of couplings, each serving a specific purpose.

Functions

Functions of coupling are useful tools to study the dynamical interaction of systems. These functions have a wide range of applications, ranging from electrochemical processes to climate processes. The research being conducted on these functions is highly interdisciplinary, and experts from different fields are contributing to this issue. As such, this issue will be of interest to scientists and engineers in many fields, including electrical engineering, physics, and mathematics.

To ensure the proper coupling of data, coupling software must perform many essential functions. These include time interpolation and timing, and data exchange between the appropriate nodes. It should also guarantee that the time step of each model is divisible by the data exchange interval. This will ensure that the data exchange occurs at the proper times.

In addition to transferring power, couplings are also used in machinery. In general, couplings are used to join two rotating pieces. However, they can also have other functions, including compensating for misalignment, dampening axial motion, and absorbing shock. These functions determine the coupling type required.

The coupling strength can also be varied. For example, the strength of the coupling can change from negative to positive. This can affect the mode splitting width. Additionally, coupling strength is affected by fabrication imperfections. The strength of coupling can be controlled with laser non-thermal oxidation and water micro-infiltration, but these methods have limitations and are not reversible. Thus, the precise control of coupling strength remains a major challenge.

Applications

Couplings transmit power from a driver to the driven piece of equipment. The driver can be an electric motor, steam turbine, gearbox, fan, or pump. A coupling is often the weak link in a pump assembly, but replacing it is less expensive than replacing a sheared shaft.

Coupling functions have wide applications, including biomedical and electrical engineering. In this book, we review some of the most important developments and applications of coupling functions in these fields. We also discuss the future of the field and the implications of these discoveries. This is a comprehensive review of recent advances in coupling functions, and will help guide future research.

Adaptable couplings are another type of coupling. They are made up of a male and female spline in a polymeric material. They can be mounted using traditional keys, keyways, or taper bushings. For applications that require reversal, however, keyless couplings are preferable. Consider your process speed, maximum load capacity, and torque when choosing an adaptable coupling.

Coupling reactions are also used to make pharmaceutical products. These chemical reactions usually involve the joining of two chemical species. In most cases, a metal catalyst is used. The Ullmann reaction, for instance, is an important example of a hetero-coupling reaction. This reaction involves an organic halide with an organometallic compound. The result is a compound with the general formula R-M-R. Another important coupling reaction involves the Suzuki coupling, which unites two chemical species.

In engineering, couplings are mechanical devices that connect two shafts. Couplings are important because they enable the power to be transmitted from one end to the other without allowing a shaft to separate during operation. They also reduce maintenance time. Proper selection, installation, and maintenance, will reduce the amount of time needed to repair a coupling.

Maintenance

Maintenance of couplings is an important part of the lifecycle of your equipment. It’s important to ensure proper alignment and lubrication to keep them running smoothly. Inspecting your equipment for signs of wear can help you identify problems before they cause downtime. For instance, improper alignment can lead to uneven wear of the coupling’s hubs and grids. It can also cause the coupling to bind when you rotate the shaft manually. Proper maintenance will extend the life of your coupling.

Couplings should be inspected frequently and thoroughly. Inspections should go beyond alignment checks to identify problems and recommend appropriate repairs or replacements. Proper lubrication is important to protect the coupling from damage and can be easily identified using thermography or vibration analysis. In addition to lubrication, a coupling that lacks lubrication may require gaskets or sealing rings.

Proper maintenance of couplings will extend the life of the coupling by minimizing the likelihood of breakdowns. Proper maintenance will help you save money and time on repairs. A well-maintained coupling can be a valuable asset for your equipment and can increase productivity. By following the recommendations provided by your manufacturer, you can make sure your equipment is operating at peak performance.

Proper alignment and maintenance are critical for flexible couplings. Proper coupling alignment will maximize the life of your equipment. If you have a poorly aligned coupling, it may cause other components to fail. In some cases, this could result in costly downtime and increased costs for the company.

Proper maintenance of couplings should be done regularly to minimize costs and prevent downtime. Performing periodic inspections and lubrication will help you keep your equipment in top working order. In addition to the alignment and lubrication, you should also inspect the inside components for wear and alignment issues. If your coupling’s lubrication is not sufficient, it may lead to hardening and cracking. In addition, it’s possible to develop leaks that could cause damage.

Modifications

The aim of this paper is to investigate the effects of coupling modifications. It shows that such modifications can adversely affect the performance of the coupling mechanism. Moreover, the modifications can be predicted using chemical physics methods. The results presented here are not exhaustive and further research is needed to understand the effects of such coupling modifications.

The modifications to coupling involve nonlinear structural modifications. Four examples of such modifications are presented. Each is illustrated with example applications. Then, the results are verified through experimental and simulated case studies. The proposed methods are applicable to large and complex structures. They are applicable to a variety of engineering systems, including nonlinear systems.

editor by czh 2023-02-24

China China cnc factory trailer coupling threaded tapered shaft for auto car coefficient of coupling

Relevant Industries: Machinery Mend Outlets, Production Plant, Printing Outlets

Framework: other people

Flexible or Rigid: Adaptable

Common or Nonstandard: Normal

Substance: Aluminium, Aluminum/Stainless Steel/brass/copper/pom

key word: adaptable spline shaft coupling

Method: machining/milling/cutting

Tolerance: .01-.05mm /can be custom-made

Function: versatile shaft coupling

High quality management: a hundred% Inspection Berore Cargo

Measurement: 19*25mm

Treatment: anodized

Inside gap: 4*4/4*6/5*5/5*6/5*8/6*6/6.35*6/6*8/ten*10mm

Support: Tailored OEM CNC Machining

1.Posters2

two.Plant Capaility

| Plant Capability | |||

| MainEquipments | CNC Lathe Machine | 35 sets | +/-.01 |

| CNC Milling Machine | 15 sets | +/-.01 | |

| CNC engraving machine | ten sets | +/-.005 | |

| Accessory Equipments | Bench drill | Laser reducing | Bending machine |

| Punching device | Flatter machine | Chamfer equipment | |

| Supplies | Aluminum Alloy:5052 /6061/ 6063 / 2017 / 7075 / and so forth. Brass Alloy:3602 / 2604 / H59 / H62 / and so on. Stainless Metal Alloy:303 / 304 / 316 / 412 / and so forth. Steel Alloy:Carbon Steel / Die Steel / etc. Other Specific Components:Lucite / Nylon / Bakelite / etc. |

||

| Area treatment method | Polishing, Sandblasting, Portray, Powder coating ,Galvanizing, Chrome plating,Black oxidation, Nickel plating, Warmth remedy, New Electric Drill Plate Cutter With Positioning Grooves Strong Metallic Gear-heads Mild Transportable Dropshipping Chemical film, Brush coating. | ||

| High quality Control | Our QC department work is inspection and last inspection. We assure you as beneath:1. Examine the raw materials before the manufacturing.2. Have inspection in the course of the production.3. Make a hundred% inspection just before the shipment. | ||

4.Milling &Turning

five.About us

six.Our staff

nine.Client pay a visit to

10.Transport&FAQ

Q: Are you investing firm or maker ?A: We are a OEM & ODM China manufacturing facility given that 2005 with the variety of substantial precision machining parts, these kinds of as cnc machining elements, vehicle lathe portion, cnc milling elements and so forth.

Q: What is the MOQA: MOQ is dependent on our consumers calls for, we welcome demo buy prior to mass creation.

Q: How does your factory make certain the item quality?A: Initial, we will put together samples for acceptance, Second, following obtaining approvalled, Take OEM ODM order Galaxy view S3 gear silicone loop 20mm 22mm universal sensible watch strap alternative our staff will established up a process craft , and kind a within drawing to follow it.3rd, durning creation, we have FQC, IQC ,IPQC and OQC to management the quality.Forth, We will final check prior to shipping and delivery to stay away from any difficulty.

Q: What is your phrases of payment ?A: T/T, paypal, ali-pay,west union, money, 30% T/T in progress , 12W0006 Total hydraulic steering equipment harmony before shippment etc.

eleven.Speak to us

Connected Goods

Types of Couplings

A coupling is a device used to join two shafts together and transmit power. Its purpose is to join rotating equipment while permitting a degree of end movement and misalignment. There are many types of couplings, and it is important to choose the right one for your application. Here are a few examples of couplings.

Mechanical

The mechanical coupling is an important component in power transmission systems. These couplings come in various forms and can be used in different types of applications. They can be flexible or rigid and operate in compression or shear. In some cases, they are permanently attached to the shaft, while in other cases, they are removable for service.

The simplest type of mechanical coupling is the sleeve coupling. It consists of a cylindrical sleeve with an internal diameter equal to the diameter of the shafts. The sleeve is connected to the shafts by a key that restricts their relative motion and prevents slippage. A few sleeve couplings also have threaded holes to prevent axial movement. This type of coupling is typically used for medium to light-duty torque.

Another type of mechanical coupling is a jaw coupling. It is used in motion control and general low-power transmission applications. This type of coupling does not require lubrication and is capable of accommodating angular misalignment. Unlike other types of couplings, the jaw coupling uses two hubs with intermeshing jaws. The jaw coupling’s spider is typically made of copper alloys. In addition, it is suitable for shock and vibration loads.

Mechanical couplings can be made from a variety of materials. One popular choice is rubber. The material can be natural or chloroprene. These materials are flexible and can tolerate slight misalignment.

Electrical

Electrical coupling is the process in which a single electrical signal is transferred from a nerve cell to another. It occurs when electrical signals from two nerve cells interact with each other in a way similar to haptic transmission. This type of coupling can occur on its own or in combination with electrotonic coupling in gap junctions.

Electrical coupling is often associated with oscillatory behavior of neurons. The mechanism of electrical coupling is complex and is studied mathematically to understand its effect on oscillatory neuron networks. For example, electrical coupling can increase or decrease the frequency of an oscillator, depending on the state of the neuron coupled to it.

The site of coupling is usually the junction of opposing cell membranes. The cellular resistance and the coupling resistance are measured in voltage-clamp experiments. This type of coupling has a specific resistance of 100 O-cm. As a result, the coupling resistance varies with the frequency.

The authors of this study noted that electrotonic coupling depends on the ratio between the resistance of the nonjunctional membranes and the junctional membranes. The voltage attenuation technique helps reveal the differences in resistance and shunting through the intercellular medium. However, it is unclear whether electrotonic coupling is electrostatically mediated.

Electrical coupling has also been suggested to play a role in the intercellular transfer of information. There are many examples that support this theory. A message can be a distinct qualitative or quantitative signal, which results in a gradient in the cells. Although gap junctions are absent at many embryonic interaction sites, increasing evidence suggests a role in information transfer.

Flexible

When it comes to choosing the right Flexible Coupling, there are several factors that you should take into account. Among these factors is the backlash that can be caused by the movement of the coupling. The reason for this problem is the fact that couplings that do not have anti-fungal properties can be easily infected by mold. The best way to avoid this is to pay attention to the moisture content of the area where you are installing the coupling. By following these guidelines, you can ensure the best possible installation.

To ensure that you are getting the most out of your flexible couplings, you must consider their characteristics and how easy they are to install, assemble, and maintain. You should also look for elements that are field-replaceable. Another important factor is the coupling’s torsional rigidity. It should also be able to handle reactionary loads caused by misalignment.

Flexible couplings come in many different types. There are diaphragm and spiral couplings. These couplings allow for axial motion, angular misalignment, and parallel offset. They have one-piece construction and are made from stainless steel or aluminum. These couplings also offer high torsional stiffness, which is beneficial for applications requiring high torques.

Flexible couplings have several advantages over their rigid counterparts. They are designed to handle misalignments of up to seven degrees and 0.025 inches. These characteristics are important in motion control applications. Flexible couplings are also inexpensive, and they do not require maintenance.

Beam

A beam coupling is a type of mechanical coupling, usually one solid piece, that connects two mechanical parts. Its performance is largely determined by the material used. Typical materials include stainless steel, aluminum, Delrin, and titanium. The beam coupling is rated for different speeds and torques. The coupling should be selected according to the application. In addition to the material, the application should also consider the speed and torque of the system.

There are two main types of beam couplings. The first is the helical beam coupling, which has a continuous multi spiral cut. This type of coupling offers a high degree of flexibility and compensates for a high degree of misalignment. The second type of beam coupling is the helical shaft coupling, which has a low torsional stiffness, which makes it ideal for small torque applications.

Another type of beam coupling is the multiple beam design, which combines two beams. It allows for more tolerance in manufacturing and installation and protects expensive components from excessive bearing loads. It also helps keep beams shorter than a single beam coupling. This type of coupling also enables a higher torque capacity and torsional stiffness.

Beam couplings can be manufactured with different materials, including stainless steel and aluminum. The “A” series is available in aluminum and stainless steel and is ideal for general-purpose and light-duty applications. It is also economical and durable. This type of coupling can also be used with low torque pumps or encoder/resolver systems.

Pin & bush

The Pin & bush coupling is a versatile, general-purpose coupling with high tensile bolts and rubber bushes. It can tolerate a wide range of operating temperatures and is suitable for use in oil and water-resistance applications. Its unique design enables it to be used in either direction. In addition, it requires no lubrication.

The pin bush coupling is a fail-safe coupling with a long service life and is used for high-torque applications. It provides torsional flexibility and dampens shocks, making it a flexible coupling that protects equipment and reduces maintenance costs. Its hubs are forged from graded cast iron for strength and durability. Besides, the coupling’s elastomer elements reduce vibration and impact loads. It also accommodates a misalignment of up to 0.5 degrees.

Pin & bush couplings are a popular choice for a variety of different applications. This coupling features a protective flange design that protects the coupling flange from wear and tear. The coupling nut is secured to one flange, while a rubber or leather bush sits between the other flange. Its unique design makes it ideal for use in applications where misalignment is a small factor. The rubber bushing also helps absorb vibration and shock.

Mesh tooth

Mesh tooth couplings are used to transfer torque between two shafts and reduce backlash. However, mesh tooth couplings have some limitations. One disadvantage is the break-away friction factor in the axial direction. This problem is caused by the high contact force between the tooth and gear mesh. This can cause unpredictable forces on the shafts.

In this paper, we present a FEM model for mesh tooth coupling. We first validate the mesh density. To do so, we compute the bolt stress as a uniaxial tensile during the tightening process. We used different mesh sizes and mesh density to validate our results.

The mesh stiffness of gear pairs is influenced by lead crown relief and misalignment. For example, if one tooth is positioned too far in the axis, the mesh stiffness will be decreased. A misaligned gear pair will lose torque capacity. A mesh tooth coupling can be lubricated with oil.

An ideal mesh tooth coupling has no gaps between the teeth, which reduces the risk of uneven wear. The coupling’s quality exposed fasteners include SAE Grade 5 bolts. It also offers corrosion resistance. The couplings are compatible with industrial environments. They also eliminate the need for selective assembly in sleeve couplings.

editor by czh 2023-02-22

China 10 pcs Motor Shaft Coupler Flexible Coupling for 3D Printer CNC 5 x 8 x 25mm CNC Motor coupling cdl

Applicable Industries: Accommodations, Garment Stores, Producing Plant, Residence Use, Development works , Vitality & Mining, Advertising Business

Versatile or Rigid: Adaptable

Regular or Nonstandard: Regular

Material: Stainless metal

Solution title: Shaft Coupler

Packaging Information: 1.Outer packing: Normal export carton with necessary shipping and delivery marks 2.Inner packing: Watertight packing with shock absorbing EPE and cardboard surrounded 3.As for every the clients needs

Port: HangZhou

Characteristics:

one hundred% Brand new and high qualitySuitable for connecting a variety of shafts inc: stepper motor outputsCompact dimension and smooth surfaceShaft coupling is frequently utilised to link servo motor stepper motor, encoder, screw driving, machine system and so on.Broadly utilised in the shafting transmission of different mechanical devices, this sort of as pumps, enthusiasts, compressors, petroleum machinery, printing machinery.

Specs:

Nominal torque: 20 (N.m)Allowable pace: ten thousand (r/m)Hole diameter: 5mm / .20inch, 8mm / .31inchOuter diameter: 19mm /.75in

Length: 25mm / .98in

Bodyweight: 155g

Package incorporated:

ten x Shaft Coupler

Company InformationHangZhou Fude Digital Technology Co., Ltd., set up in 2011, engaged in stepper motor investigation , development, generation and income , are 1 of the hello-tech enterprises. Right after several years of technologies investigating and advancement, market place advancement, we gradually grow to be the 1 of very best high quality stepper motor makers in China. In buy to offer you our greatest service and fulfill customer’s requirements , we all try out our ideal to personalize the motor and give remedies.Our organization has several planet-class clientele all in excess of the mainland China, ZheJiang , Europe and The us, Japan, Korea and other international locations or locations. Our merchandise like hybrid stepper motor , guide screw stepper motor , planetary stepper motor with gearbox and closed loop stepper motor . They are widely utilised in robots, sculpture, laser device , medical equipment, stage lighting, 3d printer,, automation products, CZPT and other equipments.

| Organization Kind | Company |

| Area | ZheJiang ,China (Mainland) |

| Year Recognized | 2011 |

| Complete Income | US$1 Million – US$2.5 Million |

| Registration No. | 440111000339089 |

| Product Certifications | A MEMBER OF ALIBABA GOLD Provider CLUB |

FAQ Q: How to select a motor to match my machine A: Make sure you give us the essential parameters of the motor. Listed here are some crucial technical specs we need to have : keeping torque, physical dimensions (diameter ,size and so on.), voltage, existing and so on. Really feel free to contact us and give the details, we are quite happy to assist you if you are baffled in assortment. Q: If I want a specific motor , can you manufacture A: Definitely, you can. If you want to change a motor in an present software,please send out us a drawing or sample and we can support you locate a suited substitution. Or, you can make contact with us and describe your application, our engineers will operate jointly with you to discover a remedy tailor-manufactured for you. Q: Can I buy samples 1st A: We stock numerous of our normal types. If you would like to take a look at a sample very first, we are happy to deliver some your way. Of training course we do not inventory specialized motors. If you have particular requirements, remember to permit us

9. Exhibition

Types of Coupling

A coupling is a device used to join two shafts together and transmit power. Its primary function is to join rotating equipment and allows for some end movement and misalignment. This article discusses different types of coupling, including Magnetic coupling and Shaft coupling. This article also includes information on Overload safety mechanical coupling.

Flexible beam coupling

Flexible beam couplings are universal joints that can deal with shafts that are offset or at an angle. They consist of a tube with couplings at both ends and a thin, flexible helix in the middle. This makes them suitable for use in a variety of applications, from motion control in robotics to attaching encoders to shafts.

These couplings are made of one-piece materials and are often made of stainless steel or aluminium alloy. However, they can also be made of acetal or titanium. While titanium and acetal are less common materials, they are still suitable for high-torque applications. For more information about beam couplings, contact CZPT Components.

Flexible beam couplings come in a variety of types and sizes. W series couplings are good for general purpose applications and are relatively economical. Stainless steel versions have increased torque capacity and torsional stiffness. Flexible beam couplings made of aluminum are ideal for servo and reverse motion. They are also available with metric dimensions.

Flexible beam couplings are made of aluminum alloy or stainless steel. Their patented slot pattern provides low bearing load and high torsional rigidity. They have a long operational life. They also require zero maintenance and can handle angular offset. Their advantages outweigh the disadvantages of traditional beam couplings.

Magnetic coupling

Magnetic coupling transfers torque from one shaft to another using a magnetic field. These couplings can be used on various types of machinery. These types of transmissions are very useful in many situations, especially when you need to move large amounts of weight. The magnetic field is also very effective at reducing friction between the two shafts, which can be extremely helpful if you’re moving heavy items or machinery.

Different magnetic couplings can transmit forces either linearly or rotated. Different magnetic couplings have different topologies and can be made to transmit force in various geometric configurations. Some of these types of couplings are based on different types of materials. For example, a ceramic magnetic material can be used for applications requiring high temperature resistance.

Hybrid couplings are also available. They have a hybrid design, which allows them to operate in either an asynchronous or synchronous mode. Hysterloy is an alloy that is easily magnetized and is used in synchronous couplings. A synchronous magnetic coupling produces a coupled magnetic circuit.

Magnetic coupling is a key factor in many physical processes. In a crystal, molecules exhibit different magnetic properties, depending on their atomic configuration. Consequently, different configurations produce different amounts of magnetic coupling. The type of magnetic coupling a molecule exhibits depends on the exchange parameter Kij. This exchange parameter is calculated by using quantum chemical methods.

Magnetic couplings are most commonly used in fluid transfer pump applications, where the drive shaft is hermetically separated from the fluid. Magnetic couplings also help prevent the transmission of vibration and axial or radial loads through the drive shaft. Moreover, they don’t require external power sources, since they use permanent magnets.

Shaft coupling

A shaft coupling is a mechanical device that connects two shafts. The coupling is designed to transmit full power from one shaft to the other, while keeping the shafts in perfect alignment. It should also reduce transmission of shock loads. Ideally, the coupling should be easy to connect and maintain alignment. It should also be free of projecting parts.

The shaft couplings that are used in machines are typically made of two types: universal coupling and CZPT coupling. CZPT couplings are designed to correct for lateral misalignment and are composed of two flanges with tongues and slots. They are usually fitted with pins. The T1 tongue is fitted into flange A, while the T2 tongue fits into flange B.

Another type of shaft coupling is known as a “sliced” coupling. This type of coupling compensates for inevitable shaft misalignments and provides high torque. Machined slits in the coupling’s outer shell help it achieve high torsional stiffness and excellent flexibility. The design allows for varying engagement angles, making it ideal for many different applications.

A shaft coupling is an important component of any machine. Proper alignment of the two shafts is vital to avoid machine breakdowns. If the shafts are misaligned, extra force can be placed on other parts of the machine, causing vibration, noise, and damage to the components. A good coupling should be easy to connect and should ensure precise alignment of the shaft. Ideally, it should also have no projecting parts.

Shaft couplings are designed to tolerate a certain amount of backlash, but it must be within a system’s threshold. Any angular movement of the shaft beyond this angle is considered excessive backlash. Excessive backlash results in excessive wear, stress, and breakage, and may also cause inaccurate alignment readings. It is therefore imperative to reduce backlash before the shaft alignment process.

Overload safety mechanical coupling

Overload safety mechanical couplings are devices that automatically disengage when the torque applied to them exceeds a specified limit. They are an efficient way to protect machinery and reduce the downtime associated with repairing damaged machinery. The advantage of overload couplings is their fast reaction time and ease of installation.

Overload safety mechanical couplings can be used in a wide range of applications. Their automatic coupling mechanisms can be used on any face or edge. In addition, they can be genderless, incorporating both male and female coupling features into a single mechanism. This means that they are both safe and gender-neutral.

Overload safety couplings protect rotating power transmission components from overloads. Overload protection devices are installed on electric motors to cut off power if the current exceeds a certain limit. Likewise, fluid couplings in conveyors are equipped with melting plug elements that allow the fluid to escape when the system becomes too hot. Mechanical force transmission devices, such as shear bolts, are designed with overload protection in mind.

A common design of an overload safety mechanical coupling consists of two or more arms and hubs separated by a plastic spider. Each coupling body has a set torque threshold. Exceeding this threshold may damage the spider or damage the jaws. In addition, the spider tends to dampen vibration and absorb axial extension. This coupling style is nearly backlash free, electrically isolating, and can tolerate very little parallel misalignment.

A mechanical coupling may also be a universal joint or jaw-clutch coupling. Its basic function is to connect the driver and driven shafts, and limits torque transfer. These devices are typically used in heavy-duty industries, such as steel plants and rolling mills. They also work well with industrial conveyor systems.

CZPT Pulley

The CZPT Pulley coupling family offers a comprehensive range of couplings for motors of all types. Not only does this range include standard motor couplings, but also servo couplings, which require ultra-precise control. CZPT Pulley couplings are also suitable for engine applications where high shocks and vibrations are encountered.

CZPT Pulley couplings have a “sliced” body structure, which allows for excellent torsional stiffness and strength. They are corrosion-resistant and can withstand high rotational speeds. The couplings’ design also ensures accurate shaft rotation while limiting shaft misalignment.

CZPT Pulley has introduced the CPU Pin Type couplings, which are effective at damping vibration and maintain zero backlash. They are also made from aluminum and are capable of absorbing heat. They come with recessed tightening screws. They can handle speeds up to 4,000 RPM, and are RoHS-compliant.

editor by czh

China best CNC Flexible Jaw Spider Plum Coupling Shaft Coupler D40 L65mm 14/17mm With a keyway 5mm at one end for nema23 nema34 motor with Good quality

Relevant Industries: Accommodations, Garment Shops, Developing Materials Retailers, Production Plant, Foodstuff & Beverage Manufacturing facility, Farms, Cafe, House Use, Meals Store, Printing Stores, Construction works , Strength & Mining, Foodstuff & Beverage Shops, Other

Construction: Jaw / Spider, Telescopic

Versatile or Rigid: Adaptable

Common or Nonstandard: Standard

Materials: Aluminium, Aluminum

Item name: Flexible Couplings Coupler

Variety: Flexible Clamp Coupling

Software: Industrial Products

Identify: Pto Shaft

Body Substance: Aluminum Alloy

Dimensions: Tailored Dimensions

Description: Custom Precision Shaft Coupling

Function: Lengthy Running Lifestyle

Packaging Particulars: For sample buy if ship by TNT, DHL, Fedex packing by paper carton for financial system shipping and delivery. For bulk buy send by sea, packing by picket carton. We sugguest customer’s acknowledge max duration 3000mm for easy and risk-free transport.

Merchandise Description Specification If you have any concerns and wants, please truly feel free to make contact with us. 7*24 :)

How to Identify a Faulty Drive Shaft

The most common problems associated with automotive driveshafts include clicking and rubbing noises. While driving, the noise from the driver’s seat is often noticeable. An experienced auto mechanic can easily identify whether the sound is coming from both sides or from one side. If you notice any of these signs, it’s time to send your car in for a proper diagnosis. Here’s a guide to determining if your car’s driveshaft is faulty:

Symptoms of Driveshaft Failure

If you’re having trouble turning your car, it’s time to check your vehicle’s driveshaft. A bad driveshaft can limit the overall control of your car, and you should fix it as soon as possible to avoid further problems. Other symptoms of a propshaft failure include strange noises from under the vehicle and difficulty shifting gears. Squeaking from under the vehicle is another sign of a faulty driveshaft.

If your driveshaft fails, your car will stop. Although the engine will still run, the wheels will not turn. You may hear strange noises from under the vehicle, but this is a rare symptom of a propshaft failure. However, you will have plenty of time to fix the problem. If you don’t hear any noise, the problem is not affecting your vehicle’s ability to move.

The most obvious signs of a driveshaft failure are dull sounds, squeaks or vibrations. If the drive shaft is unbalanced, it is likely to damage the transmission. It will require a trailer to remove it from your vehicle. Apart from that, it can also affect your car’s performance and require repairs. So if you hear these signs in your car, be sure to have it checked by a mechanic right away.

Drive shaft assembly

When designing a propshaft, the design should be based on the torque required to drive the vehicle. When this torque is too high, it can cause irreversible failure of the drive shaft. Therefore, a good drive shaft design should have a long service life. Here are some tips to help you design a good driveshaft. Some of the main components of the driveshaft are listed below.

Snap Ring: The snap ring is a removable part that secures the bearing cup assembly in the yoke cross hole. It also has a groove for locating the snap ring. Spline: A spline is a patented tubular machined element with a series of ridges that fit into the grooves of the mating piece. The bearing cup assembly consists of a shaft and end fittings.

U-joint: U-joint is required due to the angular displacement between the T-shaped housing and the pinion. This angle is especially large in raised 4x4s. The design of the U-joint must guarantee a constant rotational speed. Proper driveshaft design must account for the difference in angular velocity between the shafts. The T-bracket and output shaft are attached to the bearing caps at both ends.

U-joint

Your vehicle has a set of U-joints on the driveshaft. If your vehicle needs to be replaced, you can do it yourself. You will need a hammer, ratchet and socket. In order to remove the U-joint, you must first remove the bearing cup. In some cases you will need to use a hammer to remove the bearing cup, you should be careful as you don’t want to damage the drive shaft. If you cannot remove the bearing cup, you can also use a vise to press it out.

There are two types of U-joints. One is held by a yoke and the other is held by a c-clamp. A full ring is safer and ideal for vehicles that are often used off-road. In some cases, a full circle can be used to repair a c-clamp u-joint.

In addition to excessive torque, extreme loads and improper lubrication are common causes of U-joint failure. The U-joint on the driveshaft can also be damaged if the engine is modified. If you are driving a vehicle with a heavily modified engine, it is not enough to replace the OE U-joint. In this case, it is important to take the time to properly lubricate these components as needed to keep them functional.

tube yoke

QU40866 Tube Yoke is a common replacement for damaged or damaged driveshaft tubes. They are desirably made of a metallic material, such as an aluminum alloy, and include a hollow portion with a lug structure at one end. Tube yokes can be manufactured using a variety of methods, including casting and forging. A common method involves drawing solid elements and machining them into the final shape. The resulting components are less expensive to produce, especially when compared to other forms.

The tube fork has a connection point to the driveshaft tube. The lug structure provides attachment points for the gimbal. Typically, the driveshaft tube is 5 inches in diameter and the lug structure is 4 inches in diameter. The lug structure also serves as a mounting point for the drive shaft. Once installed, Tube Yoke is easy to maintain. There are two types of lug structures: one is forged tube yoke and the other is welded.

Heavy-duty series drive shafts use bearing plates to secure the yoke to the U-joint. All other dimensions are secured with external snap rings. Yokes are usually machined to accept U-bolts. For some applications, grease fittings are used. This attachment is more suitable for off-road vehicles and performance vehicles.

end yoke

The end yoke of the drive shaft is an integral part of the drive train. Choosing a high-quality end yoke will help ensure long-term operation and prevent premature failure. Pat’s Driveline offers a complete line of automotive end yokes for power take-offs, differentials and auxiliary equipment. They can also measure your existing parts and provide you with high quality replacements.

A U-bolt is an industrial fastener with threaded legs. When used on a driveshaft, it provides greater stability in unstable terrain. You can purchase a U-bolt kit to secure the pinion carrier to the drive shaft. U-bolts also come with lock washers and nuts. Performance cars and off-road vehicles often use this type of attachment. But before you install it, you have to make sure the yoke is machined to accept it.

End yokes can be made of aluminum or steel and are designed to provide strength. It also offers special bolt styles for various applications. CZPT’s drivetrain is also stocked with a full line of automotive flange yokes. The company also produces custom flanged yokes for many popular brands. Since the company has a comprehensive line of replacement flange yokes, it can help you transform your drivetrain from non-serviceable to serviceable.

bushing

The first step in repairing or replacing an automotive driveshaft is to replace worn or damaged bushings. These bushings are located inside the drive shaft to provide a smooth, safe ride. The shaft rotates in a rubber sleeve. If a bushing needs to be replaced, you should first check the manual for recommendations. Some of these components may also need to be replaced, such as the clutch or swingarm.

editor by czh

China Best Sales Flexible Shaft Curved Jaw CZPT /Rotex CZPT for CNC Stepper Motor with Best Sales

Item Description

Merchandise description

|

Substance |

Materials for silicon,fluorine,NBR,FPM,EPDM,SILCONE ACM,HNBR |

| Inspection Equipments | Excellent chemical and physical house, outstanding oil- resistance, high temperature stability, and so forth. |

| Tolerance | +/-.05mm |

| Drawing Structure | PDF/DWG/DXF/IGS/Stage,and so forth |

| Software field | Parts are utilized on automobiles, printing equipment, meals processing machines, textile devices, digital equipment, and so on. |

| Production process | CNC machining Broaching, Drilling, Milling, Other Machining Services, Quick Prototyping, Turning, |

| Shape | As for each your drawing Or your sample |

| Colour service | Customization |

| QC inspection |

Make positive one hundred% inspection ahead of the supply |

| Advantages | Upkeep,acturally HRC CZPT doesn’t need maintenance. |

| Environmental, elastic elements make HRC CZPT applies to a range of functioning circumstances. | |

|

Trustworthy transmission, in case of elastic element is ruined, the puppy phase wichcasted siamesedly nevertheless hold the transmission processing reliably. |

|

|

Economic, HRC couplings have presently been produced of optimization design and style,which make transmission electricity match the transmission shaft diameter. |

|

| Very good restoration potential, elastic factors can minimize the load at the peak times, and the deviation is a key thought when designing. | |

|

Adaptability of misalignment, HRC can CZPT consists of parallel change, angle change and axis change which happen some occasions. |

Software and investigation

Our warehouse

Custom made rubber areas

Custom plastic areas

Packing & Shipping and delivery

Packaging Particulars: plastic bag packing inside of, carton packing outside the house, or tailored packing.

Port:Xihu (West Lake) Dis.g port, ZheJiang metropolis.

Direct Time :

| Amount(Parts) | one – 1000 | 1001 – 10000 | 10001 – 50000 | >50000 |

| Est. Time(days) | five | 12 | 18 | To be negotiated |

Spot purchase actions

Our Solutions:

one. Convenient: twenty fourth Hours income/Right after-sales Service on the web or on the phone.

2. Quality Assurance: We will examine with you and provide you the ideal top quality cozy to your market.

three. Rapid supply: Time is cash, we promise we always will provide the goods quicker than other folks.

4. According to customers’ drawing,custom-made specs are welcomed.

5. Modest orders can be approved.

Packing

Organization Profile

SHEN ZHOU CZPT RUBBER & PLASTIC CO.,LTD was established in 2000. The factory located in industrial zone of HangZhou metropolis, ZheJiang province, china.

We have Plastic injection molding workshop and rubber compression molding workshops.Our principal merchandise involves Bakelit Knobs,Pull Take care of,rubber door stops, doorway guard, roller, rubber bumpers, Rubber grommets, vibration dampers, seals, plastic corner, injection plastic brackets, injection plastic shell.to undertake different varieties of rubber molding and plastic injection elements, customize in accordance to drawing and samples.

The products have been exported to America, Europe, Oceania, Middle East, Southeast Asia and other regions and nations, and hope to develop a lot more business Cooperation with new client from all over the globe.

FAQ

Q1: Are you a maker or a trading company?

A1: We are the authentic maker of customized rubber areas and customized plastic components.

Q2: In which is your organization situated?

A2: Our business is located in HangZhou City, ZheJiang Province, China.

Q3: Could I get free samples?

A3: We could offer little samples for totally free, but air freight or sea freight need to be borne by client side.

Q4: What ought to I provide in purchase to get an offer you?

A4: Clients are required to supply materials, interior diameter, outer diameter, CZPT part length and amount.

Q5: How is the items packed by your manufacturing facility?

A5: The products are typically packed by plastic baggage, carton bins with pallets or wooden containers.

Q6: What are the incoterms applied?

A6: The incoterms used are FOB, CIF and CFR.

Q7: What are the payment conditions accepted?

A7: We take Alibaba Trade Assurance, T/T, L/C and West Union.

Q8: What about the shipping and delivery time?

A8: The goods are generally dellivered to customer facet within 7-30 days primarily based upon the method of transportation essential.

Chain couplings need periodic lubrication, relying on the software. Lubrication is typically brushed on to the chain, and caps are utilized to support keep the coupling lubricated.

Couplings drop into two broad groups: content bending and mechanical bending. Versatile material varieties acquire adaptability by stretching or compressing elastic supplies such as rubber or bending thin metal discs or meshes. Content elastic couplings do not need lubrication, except for mesh couplings. Mechanical flex couplings take misalignment brought on by wobbling, rolling, or sliding of metallic surfaces. All metal mechanical flexible couplings require lubrication.

China Hot selling CNC Machining Motor Transmission Shaft CZPT Rigid Coupler Connector with Hot selling

Solution Description

Elastic Spider/Rotex adaptable coupling

Solution Description

Mighty can produce total sequence of Tyre Coupling

Substance: Metal+rubber

ore kind: Completed Bore/stock bore

Other Couplings:

Business Information

MIGHTY, a manufacturer belongs to SCMC Corp. which is a wholly state-owned company established in 1980, is specialized in generating precision mechanical electricity transmission merchandise. Right after years of tough function, CZPT has currently acquired the certificate of ISO9001:2000 and turn out to be a keeping firm of 3 producing factories.

Mighty’s items are mostly exported to Europe, The usa and Middle East marketplace. With the top-position management, skilled technological assist and considerable export knowledge, CZPT has established long lasting and stable organization partnership with numerous world CZPT businesses and has got very good status from globally buyers in global sales.

Tools: sawing device, CNC Lathe, drilling device, hobbing equipment, punch device, milling equipment, equipment shaper, grinding equipment, machining middle, etc.

Trade Display: PTC Asia, Canton Reasonable, Hannover Messe, IFPE

Principal Products:

Timing belt pulleys, timing bars, timing belt clamping plates.

Locking aspects and shrink discs: could be option for Ringfeder, Sati, Chiaravalli, BEA, KBK, Tollok, and so on.

V belt pulleys and taper lock bush.

Sprockets, idler, and plate wheels.

Gears and racks: spur gear, helical gear, bevel gear, worm equipment, gear rack.

Shaft couplings: miniature coupling, curved tooth coupling, chain coupling, HRC coupling, normex coupling, FCL coupling, GE coupling, rigid and flexible coupling, jaw coupling, disc coupling, multi-beam coupling, common joint, torque limiter, shaft collars.

Forging, Casting, Stamping Parts.

Other customized power transmission products and Machining Parts (OEM).

Application

1. Engineering: equipment instruments, foundry equipments, conveyors, compressors, portray systems, and so on.

2. Prescription drugs& Food Processing: pulp mill blowers, conveyor in warehouse, agitators, grain, boiler, bakery equipment, labeling machine, robots, and so forth.

3. Agriculture Industries: cultivator, rice winnower tractor, harvester, rice planter, farm gear, and so forth.

four. Texitile Mills: looms, spinning, wrappers, high-pace car looms, processing machine, twister, carding machine, ruler calendar device, higher speed winder, etc.

5. Printing Equipment: newspaper push, rotary device, screen printer equipment, linotype equipment offset printer, and many others.

six. Paper Industries: chipper roll grinder, cut off saw, edgers, flotation mobile and chips saws, and many others.

seven. Building Design Equipment: buffers, elevator flooring polisher mixing machine, vibrator, hoists, crusher, and many others.

eight. Office Equipments: typewriter, plotters, digicam, cash travel, funds sorting device, info storage gear, etc.

9. Glass and Plastic Industries: conveyor, carton sealers, grinders, creeper paper manufacturing machine, lintec backing, and so on.

ten. Residence Appliances: vacuum cleaner, laundry device, icecream machine, stitching machine, kitchen equipments, and many others.

FAQ

Q: Are you buying and selling firm or manufacturer ?

A: We are manufacturing unit.

Q: How lengthy is your shipping time?

A: Normally it is 5-10 days if the merchandise are in stock. or it is fifteen-twenty days if the products are not in inventory, it is according to amount.

Q: Do you offer samples ? is it free or extra ?

A: Indeed, we could supply the sample for free of charge cost but do not pay out the expense of freight.

Q: What is your phrases of payment ?

A: Payment=1000USD, 30% T/T in CZPT ,balance just before shippment.

If you have one more question, pls truly feel cost-free to make contact with us as under:

Contacts

We warmly welcome buddies from domestic and abroad arrive to us for business negotiation and cooperation for mutual advantage. To offer clients excellent top quality merchandise with very good price tag and punctual shipping time is our obligation.

Any question or inquiry, pls contact us without hesitate, we CZPT any of your inquiry will get our prompt consideration and reply!

Sleeve Couplings Sleeve couplings transmit lower to average shear torques in between related equipment through elastic inserts with exterior splines mated to inside splines. The insert content is usually EPDM, Neoprene or Hytrel, and the insert can be a a single-piece or two-piece layout. Reasonable eccentricity Torsional damping (vibration) Finish float with minimum axial enjoy Lower to moderate torque, common-goal applications

Jaw Coupling A jaw coupling is a materials elastic coupling that transmits torque by compressing a resilient star-shaped insert placed amongst two intermeshing jaws. Flexible elements are normally created of NBR, Polyurethane, Hytrel, or Bronze Torque for basic purpose apps

CNC Machined Shaft Wheel Molded-in Blind Threaded Inserts for Plastic, Brass Inserts Screw

CNC CZPTd Shaft Wheel Molded-in Blind Threaded Inserts for CZPT, Brass Inserts CZPT

Items Description

large top quality Flange and Slicing Hole brass insert

Quality CZPT: CZPT, TS16949, SGS

Location of Origin: HangCZPT, China

Fashion:Cylinder

Use: CZPT, aerospace

Wire Diameter: M1.~M6.

Surface Complete:white zinc

Load Kind: Flange and Reducing

| Material | Brass,Stainless Metal,Carbon metal,Aluminum alloy,in accordance to customer’s need |

| End | Zn/Ni/Tin/Au plating,Black Oxide,Anodizing and so on. |

| Insert Methods | By Ultrasonic,Heat staking,Insert Molding,Chilly push-in Techniques |

| Top quality Handle | Stick to Drawing Spec |

| Administration Program | CZPT:2008 |

| Certification | SGS,RoHS,Material Certication,PPAP |

| Direct Time | 5-ten working days |

| Samples | Welcome |

| Shipping expression | By DHL,UPS,TNT,FedEx,EMS,By CZPT,By Air |

| Creation Ability | Car-lathe turning:ODΦ0.five-20mm,Tol.±0.01mm |

| CNC lathe turning:ODΦ0.five-250mm,Tol.±0.005mm | |

| CNC Milling:800x600mm(LxW),Tol.±0.05mm | |

| Grinding:Tol.±0.002mm | |

| CZPT heading & rolling:Metric .eight-M6,Unified Imperial#-1/4” | |

| Stamping:200T max |

Business Data:

Launched day: Established in 2016, and have six a long time encounters in spring generation

Enterprise Kind: Maker

Business Assortment: Tools&CZPT

Major Merchandise: brass insert,CZPT, Elastic mobile

Management Technique Certification: CZPT, TS16949, SGS

Factory