Product Description

Product Description

Coupling Deatails

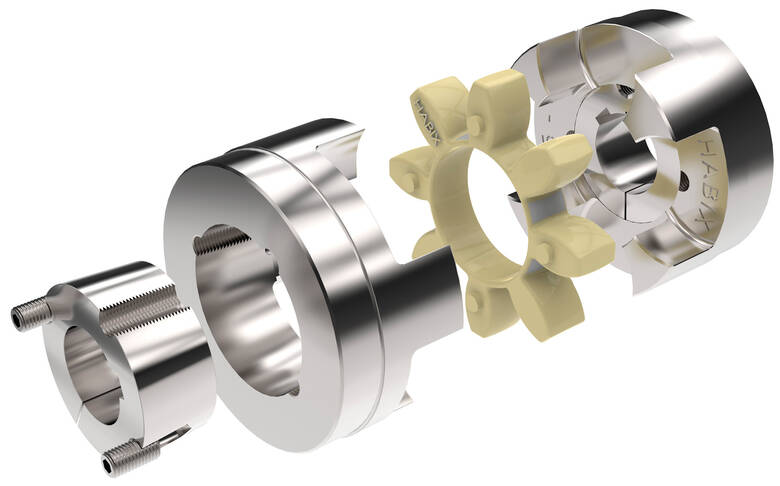

Name: High precision plum blossom

coupling Model: LM-Material: Aviation Aluminum Alloy

Working temperature: -40 ° C ~ 100 ° C

Support customization: Factory direct sales support customization.

Features:

1.Intermediate Elastomer Connection-Absorbs vibration, compensates for radial, angular, and axial 2.misalignment

3.Oil resistance and electrical insulation

4.Clockwise and counterclockwise rotation characteristics are identical-there are 3 different hardness 5.elastomer

6.Fixation by clamping screw.

|

Model parameter |

ΦD |

L |

LF |

LP |

F |

M |

Tightening screw torque |

|

(N.M) |

|||||||

|

GF-14X22 |

14 |

22 |

14.3 |

6.6 |

3.8 |

M 3 |

0.7 |

|

GF-20X25 |

20 |

25 |

16.7 |

8.6 |

4 |

M 3 |

0.7 |

|

GF-20X30 |

20 |

30 |

19.25 |

8.6 |

5.3 |

M 4 |

1.7 |

|

GF-25X30 |

25 |

30 |

20.82 |

11.6 |

5.6 |

M 4 |

1.7 |

|

GF-25X34 |

25 |

34 |

22.82 |

11.6 |

5.6 |

M 4 |

1.7 |

|

GF-30X35 |

30 |

35 |

23 |

11.5 |

5.75 |

M 4 |

1.7 |

|

GF-30X40 |

30 |

40 |

25.6 |

11.5 |

10 |

M 4 |

1.7 |

|

GF-40X50 |

40 |

50 |

32.1 |

14.5 |

10 |

M 5 |

4 |

|

GF-40X55 |

40 |

55 |

34.5 |

14.5 |

10 |

M 5 |

4 |

|

GF-40X66 |

40 |

66 |

40 |

14.5 |

12.75 |

M 5 |

4 |

|

GF-55X49 |

55 |

49 |

32 |

16.1 |

13.5 |

M 6 |

8.4 |

|

GF-55X78 |

55 |

78 |

46.4 |

16.1 |

15.5 |

M 6 |

8.4 |

|

GF-65X80 |

65 |

80 |

48.5 |

17.3 |

18.1 |

M 8 |

10.5 |

|

GF-65X90 |

65 |

90 |

53.5 |

17.3 |

18.1 |

M 8 |

10.5 |

Product Parameters

Detailed Photos

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Reducing Vibration and Shock in Machinery with Elastic Couplings

Elastic couplings play a crucial role in minimizing vibration and shock in machinery by offering flexibility and damping characteristics. Here’s how they contribute to this important function:

- Vibration Absorption: Elastic couplings are designed with flexible elements that can absorb and dampen vibrations generated by rotating machinery. These flexible elements act as shock absorbers, reducing the transmission of vibrations to other parts of the system.

- Isolation: The inherent flexibility of elastic couplings isolates vibrations and shocks from one side of the coupling to the other. This prevents vibrations from propagating throughout the connected components, helping to protect sensitive equipment and improve overall system performance.

- Resonance Damping: Elastic couplings can help dampen resonance frequencies that can occur in machinery during operation. By absorbing and dissipating energy, they reduce the risk of resonance-related issues that can lead to mechanical failure or decreased efficiency.

- Smooth Torque Transmission: Elastic couplings offer a smooth torque transmission that helps reduce sudden torque spikes and shocks during start-up or sudden load changes. This prevents abrupt mechanical stresses that can lead to vibration and shock propagation.

- Increased Equipment Lifespan: By minimizing the impact of vibrations and shocks, elastic couplings contribute to the longevity of connected machinery and components. Reduced vibration-related wear and tear can extend the service life of the entire system.

Overall, elastic couplings are effective tools for managing vibration and shock in machinery, enhancing operational reliability, reducing maintenance needs, and maintaining optimal performance.

Installation Guidelines for Integrating Elastic Couplings

Proper installation of elastic couplings is essential to ensure their optimal performance and longevity. Engineers should follow these guidelines:

1. Alignment: Before installation, ensure that the connected shafts are properly aligned within the manufacturer’s specified tolerances. Misalignment can lead to premature wear and reduced coupling effectiveness.

2. Lubrication: Some elastic couplings require lubrication to maintain smooth operation. Follow the manufacturer’s recommendations for the type and amount of lubricant to use.

3. Mounting: Securely mount the elastic coupling onto the shafts using appropriate torque values for the coupling’s fasteners. Use a torque wrench to prevent over-tightening, which can damage the coupling or the shafts.

4. Inspection: Inspect the coupling for any signs of damage or defects before installation. Any issues should be addressed before the coupling is put into operation.

5. Clearance: Maintain proper clearance between the coupling and surrounding components to prevent interference during operation, especially if the coupling flexes during use.

6. Environmental Factors: Consider the operating environment, such as temperature, humidity, and exposure to chemicals, when selecting an appropriate elastic coupling material.

7. Manufacturer’s Recommendations: Always refer to the manufacturer’s installation guidelines and instructions specific to the type and model of elastic coupling being used.

Following these installation guidelines will help ensure the effective and safe integration of elastic couplings into mechanical systems.

Industries Using Elastic Couplings

Elastic couplings find extensive use in various industries due to their unique benefits:

- Industrial Manufacturing: Elastic couplings are widely used in manufacturing equipment, conveyors, and assembly lines to maintain smooth operation and reduce vibrations.

- Automotive: Automotive applications include engine components, powertrain systems, and vehicle suspension systems where flexibility and vibration dampening are crucial.

- Power Generation: Elastic couplings are used in power generation equipment such as generators, turbines, and pumps to absorb torsional vibrations and enhance efficiency.

- Aerospace: In aerospace applications, elastic couplings help dampen vibrations in critical components like aircraft engines and control systems.

- Renewable Energy: Wind turbines and solar tracking systems benefit from elastic couplings to accommodate misalignments and vibrations caused by changing wind conditions.

- Mining: Mining equipment such as crushers, conveyors, and screens utilize elastic couplings to handle varying loads and minimize shock loads.

- Marine: Elastic couplings are used in marine propulsion systems and ship equipment to manage torque fluctuations and reduce vibrations.

These industries rely on elastic couplings to enhance performance, extend machinery lifespan, and minimize downtime due to vibrations, misalignments, and shock loads.

editor by CX 2024-05-07

China supplier Star Elastic with Enlarged Shaft Hole Flexible Coupling for Machine Tools

Product Description

Product Description

Product Parameters

| product | Star Elastic with Enlarged Shaft Hole Flexible Coupling for Machine tools |

| material | stainless steel , iron , aluminum ,bronze ,carbon steel ,brass etc . |

| size | ISO standard ,customer requirements |

| BORE | Finished bore, Pilot Bore, Special request |

| surface treatment | Carburizing and Quenching,Tempering ,Tooth suface high quenching Hardening,Tempering |

| Processing Method | Molding, Shaving, Hobbing, Drilling, Tapping, Reaming, Manual Chamfering, Grinding etc |

| Heat Treatment | Quenching & Tempering, Carburizing & Quenching, High-frequency Hardening, Carbonitriding…… |

| Package | Wooden Case/Container and pallet, or made-to-order |

| Certificate | ISO9001 ,SGS |

| Machining Process | Gear Hobbing, Gear Milling, Gear Shaping, Gear Broaching, Gear Shaving, Gear Grinding and Gear Lapping |

| Applications | Toy, Automotive, instrument, electrical equipment, household appliances, furniture, mechanical equipment,daily living equipment, electronic sports equipment, , sanitation machinery, market/ hotel equipment supplies, etc. |

| Testing Equipment | Rockwell hardness tester 500RA, Double mesh instrument HD-200B & 3102,Gear measurement center instrument CNC3906T and other High precision detection equipments |

workshop & equipment

Production process

Certifications

Our Advantages

1 . Prioritized Quality

2 .Integrity-based Management

3 .Service Orientation

4 .150+ advanced equipment

5 .10000+ square meter factory area

6 .200+ outstanding employees

7 .90% employees have more than 10 year- working experience in our factory

8 .36 technical staff

9 .certificate ISO 9001 , SGS

10 . Customization support

11 .Excellent after-sales service

shipping

sample orders delivery time:

10-15 working days as usual

15-20 working days in busy season

large order leading time :

20-30 working days as usual

30-40 working days in busy season

FAQ

1. why should you buy products from us not from other suppliers?

We are a 32 year-experience manufacturer on making the gear, specializing in manufacturing varieties of gears, such as helical gear ,bevel gear ,spur gear and grinding gear, gear shaft, timing pulley, rack, , timing pulley and other transmission parts . There are 150+ advanced equipment ,200+ excellent employees ,and 36 technical staff . what’s more ,we have got ISO9001 and SGS certificate .

2 .Do you accept small order?

If your order bearings are our standard size, we accept even 1pcs.

3 .How long is the delivery?

A: Small orders usually takes 10-15 working days,big order usually 20-35 days, depending on orders quantity and whether are standard size.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Maintenance Requirements for Optimal Performance of Elastic Couplings

Maintaining elastic couplings is essential to ensure their optimal performance and longevity. Following these maintenance guidelines can help prevent premature wear and failure:

- Regular Inspection: Periodically inspect the coupling for signs of wear, such as cracks, deformities, or visible damage. This can help identify issues early and prevent further damage.

- Lubrication: Some elastic couplings require lubrication to reduce friction and wear. Follow the manufacturer’s recommendations for lubrication intervals and use compatible lubricants.

- Torque Check: Check the coupling’s torque values to ensure they are within the specified range. This helps maintain proper torque transmission and prevents overloading.

- Alignment Check: Monitor the alignment of the connected shafts regularly. Misalignment can cause excessive stress on the coupling, leading to premature failure.

- Vibration Analysis: Perform vibration analysis to identify any abnormal vibrations in the system. Excessive vibrations could indicate coupling or system issues that need attention.

- Temperature and Environment: Ensure that the coupling operates within the recommended temperature and environmental limits. Extreme conditions can affect the coupling’s material properties and performance.

- Coupling Wear: Keep track of the coupling’s wear over time. Depending on the application, the coupling might need replacement after a certain period of service.

- Expert Inspection: If any unusual symptoms or problems arise, consider having the coupling inspected by a qualified technician or engineer to diagnose the issue accurately.

Adhering to these maintenance practices helps extend the service life of elastic couplings, ensures reliable performance, and minimizes unexpected downtime and costly repairs.

Alternatives to Elastic Couplings for Flexible Connections in Machinery

There are several alternatives to elastic couplings for achieving flexible connections in machinery:

1. Universal Joints: Universal joints, also known as U-joints, are mechanical devices that allow rotational motion between two shafts at different angles. They are suitable for applications with significant misalignment.

2. Cardan Shafts: Cardan shafts consist of a series of universal joints connected in a line, allowing for the transmission of torque and rotation in complex systems.

3. Oldham Couplings: Oldham couplings use sliding disks to transmit torque while accommodating small misalignments. They are suitable for applications where precise positioning is required.

4. Beam Couplings: Beam couplings use a flexible beam to transmit torque and compensate for angular and axial misalignment.

5. Diaphragm Couplings: Diaphragm couplings use thin diaphragms to transmit torque while compensating for misalignment. They are often used in high-performance applications.

6. Gear Couplings: Gear couplings use teethed gears to transmit torque and accommodate misalignment. They are suitable for heavy-duty applications.

7. Chain Couplings: Chain couplings use roller chains to transmit torque and handle misalignment. They are commonly used in low-speed, high-torque applications.

8. Bellows Couplings: Bellows couplings use a bellows-like flexible element to transmit torque while compensating for misalignment.

Each of these alternatives has its own advantages and limitations, and the choice depends on the specific requirements of the application.

Industries Using Elastic Couplings

Elastic couplings find extensive use in various industries due to their unique benefits:

- Industrial Manufacturing: Elastic couplings are widely used in manufacturing equipment, conveyors, and assembly lines to maintain smooth operation and reduce vibrations.

- Automotive: Automotive applications include engine components, powertrain systems, and vehicle suspension systems where flexibility and vibration dampening are crucial.

- Power Generation: Elastic couplings are used in power generation equipment such as generators, turbines, and pumps to absorb torsional vibrations and enhance efficiency.

- Aerospace: In aerospace applications, elastic couplings help dampen vibrations in critical components like aircraft engines and control systems.

- Renewable Energy: Wind turbines and solar tracking systems benefit from elastic couplings to accommodate misalignments and vibrations caused by changing wind conditions.

- Mining: Mining equipment such as crushers, conveyors, and screens utilize elastic couplings to handle varying loads and minimize shock loads.

- Marine: Elastic couplings are used in marine propulsion systems and ship equipment to manage torque fluctuations and reduce vibrations.

These industries rely on elastic couplings to enhance performance, extend machinery lifespan, and minimize downtime due to vibrations, misalignments, and shock loads.

editor by CX 2024-04-03

China factory Wsd Professional CZPT Flexible Shaft Machinery Parts Joint near me supplier

Product Description

Elastic Common Shaft Coupling

Features:

1. It is appropriate for transmission CZPT room on the same aircraft of 2 axis angle beta β≤45°, the nominal torque transmission eleven.2-1120N.

two.The WSD kind is a solitary CZPT universal coupling, and the WS variety is a double CZPT universal coupling.

three.Every single part among the largest axis angle 45º.

four.The finished hole H7, in accordance to the specifications of keyseating, 6 sq. hole and sq. gap.

5.The angle between the 2 axes is permitted in a minimal range as the perform demands change.

| NO | Tn/N·m |

d(H7) | D | L0 | L | L1 | m/kg | I/kg·m2 | ||||||||||

| WSD | WS |

WSD | WS | WSD | WS | |||||||||||||

| Y | J1 | Y | J1 | Y | J1 | Y | J1 | Y | J1 | Y | J1 | Y | J1 | |||||

| WS1 WSD1 |

11.2 | eight | 16 | 60 | – | 80 | – | 20 | – | 20 | 0.23 | – | 0.32 | – | 0.06 | – | 0.08 | – |

| nine | ||||||||||||||||||

| 10 | 66 | 60 | 86 | 80 | 25 | 22 | .two | .29 | .05 | .07 | ||||||||

| WS2 WSD2 |

22.4 | 10 | 20 | 70 | 64 | 96 | 90 | 26 | 0.sixty four | 0.57 | 0.ninety three | 0.88 | 0.one | 0.09 | 0.fifteen | 0.fifteen | ||

| 11 | ||||||||||||||||||

| 12 | eighty four | seventy four | 110 | 100 | 32 | 27 | ||||||||||||

| WS3 WSD3 |

45 | 12 | 25 | 90 | 80 | 122 | 112 | 32 | 1.forty five | 1.three | 2.one | 1.ninety five | 0.seventeen | 0.15 | 0.24 | 0.22 | ||

| 14 | ||||||||||||||||||

| WS4 WSD4 |

71 | 16 | 32 | 116 | 82 | 154 | 130 | 42 | 30 | 38 | 5.92 | 4.86 | 8.fifty six | 0.48 | 0.39 | 0.32 | 0.56 | 0.forty nine |

| 18 | ||||||||||||||||||

| WS5 WSD5 |

140 | 19 | 40 | 144 | 116 | 192 | 164 | 48 | 16.three | 12.9 | 24 | 20.6 | 0.72 | 0.59 | 1.04 | 0.ninety one | ||

| 20 | 52 | 38 | ||||||||||||||||

| 22 | ||||||||||||||||||

| WS6 WSD6 |

280 | 24 | 50 | 152 | 124 | 210 | 182 | 52 | 38 | 58 | 45.7 | 36.seven | 68.9 | 59.7 | 1.28 | 1.03 | 1.89 | 1.sixty four |

| 25 | 172 | 136 | 330 | 194 | 62 | 44 | ||||||||||||

| 28 | ||||||||||||||||||

| WS7 WSD7 |

560 | 30 | 60 | 226 | 182 | 296 | 252 | 82 | 60 | 70 | 148 | 117 | 207 | 177 | 2.82 | 2.31 | 3.9 | 3.38 |

| 32 | ||||||||||||||||||

| 35 | ||||||||||||||||||

| WS8 WSD8 |

1120 | 38 | 75 | 240 | 196 | 332 | 288 | 92 | 396 | 338 | 585 | 525 | 5.03 | 4.41 | 7.25 | 6.63 | ||

| 40 | 300 | 244 | 392 | 336 | 112 | 84 | ||||||||||||

| forty two | ||||||||||||||||||

Our company supplies different varieties of items. Large good quality and reasonable value. We adhere to the theory of “good quality initial, provider initial, continuous improvement and innovation to satisfy the customers” for the management and “zero defect, zero issues” as the top quality aim. To ideal our services, we provide the items with good good quality at the realistic value.

Our Services

24 several hours on-line provider

Enquiry will be replied in 2 hours

Factory Address:

No. 11, HangZhou Road, ChengNan Industrial Park, HangZhou, HangZhou, ZheJiang , China

FAQ

one. Are u a company?

We are a skilled maker specializing in producing cardan shaft and varioue sequence of couplings. We supply couplings for the wholesalers and dealers from different nations around the world.

2. Can you do OEM?

Yes, we can. We can do OEM & ODM for all the buyers with personalized artworks of PDF or AI structure.

three. How does your manufacturing facility do relating to good quality handle?

Quality is priority! We often connect excellent significance to good quality controlling from the very beginning to the very finish:

1) Firstly, we have specialised QC division to control the good quality, and we also take the third formal govt to inspect the cargoes prior to supply.

two) Next, we have all in depth data for nonconformity merchandise, then we will make summary in accordance to these records, steer clear of it happen once more.

three) Thirdly, We do notice the pertinent codes of carry out & laws from federal government in atmosphere, human right aspects like no children labor, no prisoner labor and so on.

4. How can I get samples?

We are appreciated that new consumers pay for the specific price for samples and this cost will be deducted when orders are launched.

Welcome to personalize items from our manufacturing facility and pls send out us a lot more details about your acquiring.

Thank you for your time and interest.

The tire coupling has rubber or polyurethane components on equally hubs. When shearing, the rubber aspects transmit torque. Reduces transmission of shock hundreds or vibrations. Easy to assemble without shifting hubs or connecting gear, with substantial misalignment ability. Medium and large speed procedure with broad torque assortment

The roller chain coupling is composed of two radial sprocket hubs that mesh with a double pitch roller chain. Chain couplings are employed for reduced to medium torque and speed apps. The meshing of the sprocket and chain transmits torque, and the connected perform accommodates angular, parallel and axial misalignment.

China best GR Elastic Spiders for Shaft CZPT near me supplier

Merchandise Description

GR elastic spider is ideal for all HUB equipment. It is also the recommended elastomer insert for all applications in general engineering/hydraulics.

Advantages:

Really resistance to use, oil, CZPT and ageing. Also resistant to hydrolysis(ideal for tropical climates).

Safeguard the travel from dynamic overload.

Excellent physical qualities.

Vast selection of application.

Failure protection.

Simple set up.

Operating situations

Temperature: -forty~+100° C

Torque: 22.4-2500NM

Content

Content: CPU/TPU

Hardness: Yellow: 93 Shore A

Red: ninety eight Shore A

Good Top quality, Aggressive Cost.

Welcome to contact us for thorough data.

Diaphragm Couplings Diaphragm couplings use a solitary or a sequence of plates or diaphragms as adaptable factors. It transfers torque from the outer diameter of the flex plate to the internal diameter, through the spool or spacer, and then from the internal diameter to the outer diameter. When the diaphragm is subjected to misalignment, the outer diameter is deflected relative to the internal diameter. For example, axial displacement makes an attempt to stretch the diaphragm, which final results in a mixture of elongation and bending of the diaphragm profile. Angular, parallel and substantial axial misalignment permitted Excellent for large torque, higher pace purposes

Couplings slide into two wide groups: substance bending and mechanical bending. Flexible substance varieties achieve adaptability by stretching or compressing elastic components this kind of as rubber or bending thin metal discs or meshes. Content elastic couplings do not demand lubrication, except for mesh couplings. Mechanical flex couplings acknowledge misalignment brought on by wobbling, rolling, or sliding of metal surfaces. All metal mechanical flexible couplings demand lubrication.

China supplier CZPT Customized Flexible Oldham CZPT Set Screw Clamp Type Shaft CZPT for Servo Motor with Best Sales

Item Description

DDensen customized Flexible Oldham CZPT Established Screw Clamp Kind Shaft CZPT for Servo Motor

| Solution Title | Adaptable Oldham CZPT Established Screw Clamp Kind Shaft CZPT for Servo Motor |

| DN mm | 12~160mm |

| Rated Torque | 25~25000 N·m |

| Allowable speed | 15300~1500 N·m |

| Substance | 35CrMo/ZG270/forty five# steel/Aluminum alloy |

| Software | Widely utilised in metallurgy, mining, engineering and other fields. |

Product show

Company Data

Products

Standard case of diaphragm CZPT applied to variable frequency pace control products

JMB kind CZPT is utilized to HangZhou Oilfield Thermal Power Plant

According to the specifications of HangZhou Electric Electrical power Company, HangZhou Oilfield Thermal Electrical power Plant must dynamically change the energy generation in accordance to the load of the electrical power grid and market need, and have out the transformation of the frequency converter and the suction fan. The motor was at first a 1600KW, 730RPM non-frequency variable velocity motor matched by HangZhou Motor Manufacturing facility. The velocity manage method after modifying the frequency is manual manage. Push the button pace to boost 10RPM or drop 10RPM. The CZPT is still the authentic elastic decoupling coupling, and the elastic de-coupling CZPT after frequency conversion is often ruined, which immediately affects the typical electricity generation.

It is identified by means of investigation that in the procedure of frequency conversion velocity regulation, the pin of the CZPT can not bear the inertia of the speed regulation method (the diameter of the enthusiast impeller is 3.3 meters) and is cut off, which has fantastic hurt to the motor and the fan.

Afterwards, they switched to the JMB460 double-diaphragm wheel-variety CZPT of our manufacturing unit (patent number: ZL.99246247.9). Following 1 hour of damaging experiment and a lot more than 1 calendar year of operation check, the tools is operating very effectively, and there is no Replace the diaphragm. 12 models have been rebuilt and the procedure is in great condition.

Other Application Circumstance

Spare parts

Packaging & Shipping and delivery

Speak to us

Couplings slide into two wide groups: substance bending and mechanical bending. Versatile content types gain flexibility by stretching or compressing elastic components this sort of as rubber or bending slim metallic discs or meshes. Content elastic couplings do not call for lubrication, apart from for mesh couplings. Mechanical flex couplings accept misalignment caused by wobbling, rolling, or sliding of metallic surfaces. All steel mechanical flexible couplings require lubrication.

Diaphragm Couplings Diaphragm couplings use a one or a series of plates or diaphragms as adaptable components. It transfers torque from the outer diameter of the flex plate to the inner diameter, by means of the spool or spacer, and then from the internal diameter to the outer diameter. When the diaphragm is subjected to misalignment, the outer diameter is deflected relative to the interior diameter. For instance, axial displacement makes an attempt to stretch the diaphragm, which outcomes in a combination of elongation and bending of the diaphragm profile. Angular, parallel and higher axial misalignment permitted Excellent for large torque, higher speed programs

China Professional Zero Backlash Germany Quality Shaft Flexible Jaw Lovejoy Ktr Couplings near me supplier

Product Description

Flexible jaw coupling

Product Description

We could supply JC-S,JC-C sequence Jaw Coupling

JC-S sequence : Established screw type Jaw Coupling

Clamp type Binodal coupling

JC-C collection : Clamp type Jaw Coupling

Ringfeder Jaw Coupling

Advantages

one.Jaw coupling is made of hard aluminium alloy

2.Can be with keyway if you need

three.Polyurethane elastomer material

4.Precision can be within 0.01mm

five.Can customize the length or as your drawing

six.Zero Backlash and 0 repair rate

7.Very famous in China and all over the world

eight.Can replce KTR very very good quality

9.Large quanity will be with very good price

ten.Supply OEM service

Jaw CZPT catalogues

Connected Products

Jaw CZPT – Clamp Type Metal Bellows Coupling Flexible Beam Coupling

Disc Coupling Oldham Coupling Rigid Coupling

Business Data

Gear: sawing device, CNC Lathe, drilling device, hobbing equipment, punch equipment, milling machine, equipment shaper, grinding device, machining heart, and so forth.

Trade Show: PTC Asia, Canton Honest, Hannover Messe, IFPE

Principal Products:

Timing belt pulleys, timing bars, timing belt clamping plates.

Locking components and shrink discs: could be substitute for Ringfeder, Sati, Chiaravalli, BEA, KBK, Tollok, etc.

V belt pulleys and taper lock bush.

Sprockets, idler, and plate wheels.

Gears and racks: spur gear, helical equipment, bevel gear, worm gear, equipment rack.

Shaft couplings: miniature coupling, curved tooth coupling, chain coupling, HRC coupling, normex coupling, FCL coupling, GE coupling, rigid and versatile coupling, jaw coupling, disc coupling, multi-beam coupling, universal joint, torque limiter, shaft collars.

Forging, Casting, Stamping Parts.

Other customized power transmission products and Machining Parts (OEM).

Packing

All the items will be packed meticulously with foamed plastics by our workers.

We provide the plywood containers for the mass purchase. and carton boxes for the samples.

Shipping and delivery

a. FedEx/DHL/UPS/TNT/China Put up for samples.

b. By Air or by Sea for batch goods, for FCL Airport/ Port receiving,

c. Customers specifying freight forwarders or negotiable shipping methods

Application

1. Engineering: device resources, foundry equipments, conveyors, compressors, portray systems, and so forth.

two. Pharmaceuticals& Food Processing: pulp mill blowers, conveyor in warehouse, agitators, grain, boiler, bakery device, labeling machine, robots, and so forth.

three. Agriculture Industries: cultivator, rice winnower tractor, harvester, rice planter, farm products, and many others.

4. Texitile Mills: looms, spinning, wrappers, higher-velocity automobile looms, processing equipment, tornado, carding device, ruler calendar device, substantial pace winder, and many others.

five. Printing Machinery: newspaper push, rotary equipment, display screen printer equipment, linotype equipment offset printer, and many others.

six. Paper Industries: chipper roll grinder, cut off noticed, edgers, flotation cell and chips saws, etc.

7. Developing Construction Machinery: buffers, elevator floor polisher mixing equipment, vibrator, hoists, crusher, etc.

eight. Business office Equipments: typewriter, plotters, camera, funds travel, funds sorting machine, info storage tools, and so on.

9. Glass and Plastic Industries: conveyor, carton sealers, grinders, creeper paper producing equipment, lintec backing, and so forth.

10. Residence Appliances: vacuum cleaner, laundry equipment, icecream machine, sewing equipment, kitchen area equipments, etc.

FAQ

Q: Are you buying and selling firm or producer ?

A: We are factory.

Q: How extended is your delivery time?

A: Normally it is 5-ten days if the products are in inventory. or it is 15-twenty days if the items are not in stock, it is according to amount.

Q: Do you give samples ? is it free of charge or added ?

A: Indeed, we could offer the sample for cost-free charge but do not pay the price of freight.

Q: What is your phrases of payment ?

A: Payment=1000USD, 30% T/T in CZPT ,balance prior to shippment.

If you have yet another query, pls truly feel free of charge to contact us as below:

Contacts

We warmly welcome buddies from domestic and overseas occur to us for enterprise negotiation and cooperation for mutual gain. To offer clients exceptional quality merchandise with good cost and punctual supply time is our duty.

Any question or inquiry, pls contact us without hesitate, we CZPT any of your inquiry will get our prompt attention and reply!

Consisting of two radially slotted hubs and a serpentine spring metal band, the mesh coupling provides the torsional damping and flexibility of an elastomer, but with the toughness of steel. Grid couplings transmit torque and adjust angular, parallel and axial misalignment from 1 hub to yet another by oscillating and sliding a tapered grid in the hub grooves. The mesh cross part is typically tapered for greater hub speak to and simpler assembly. Lubrication is needed thanks to the motion among the speak to hub and the mesh metallic parts.

Consisting of two radially slotted hubs and a serpentine spring metal band, the mesh coupling provides the torsional damping and adaptability of an elastomer, but with the energy of metal. Grid couplings transmit torque and change angular, parallel and axial misalignment from one hub to another by oscillating and sliding a tapered grid in the hub grooves. The mesh cross section is normally tapered for greater hub contact and easier assembly. Lubrication is essential owing to the movement among the get in touch with hub and the mesh metallic elements.

China wholesaler High Quality Hardy Spicer Cardan Constant-Velocity Propshaft Steering Shaft Removing Pto CZPT Double Front Rear Best Universal Joint near me supplier

Merchandise Description

high quality Hardy Spicer Cardan Consistent-velocity propshaft steering shaft removing pto CZPT double front rear greatest universal joint

Diaphragm Couplings Diaphragm couplings use a single or a sequence of plates or diaphragms as versatile aspects. It transfers torque from the outer diameter of the flex plate to the inner diameter, through the spool or spacer, and then from the inner diameter to the outer diameter. When the diaphragm is subjected to misalignment, the outer diameter is deflected relative to the interior diameter. For instance, axial displacement attempts to stretch the diaphragm, which outcomes in a mixture of elongation and bending of the diaphragm profile. Angular, parallel and high axial misalignment authorized Best for high torque, higher speed purposes

Mechanical bending couplings acknowledge misalignment of metal surfaces by wobbling, rolling or sliding. All metallic mechanical bending couplings need lubrication. Illustrations of mechanical bending couplings are equipment, grid and roller chain couplings. Gear couplings transmit the maximum torque and minimum diameter of any elastic coupling.

China wholesaler Tire Couplings F60 F70 F80 F90 F100 F110 F120 F140 F160 F180 Ffx Fena Flex Shaft Tyre CZPT with Fras Tyre Body near me supplier

Solution Description

| Merchandise Title | Tyre Coupling | Place of origin | China |

| Manufacturer | Mighty | Material | Metal /Cast Iron |

one.Low MOQ: It can meet your promotional business very well.

2.OEM&ODM: Accepted.

three.Good Service: We treat every clients like family.

four.Good Quality: 100% inspectionwith strict quality control system(We have passed the ISO9001:2008 quality system authentication).

five.Prompt Feedback: We reply every clients within 2 hours except we are dealing with urgent things.

six.Accurate delivery: We ship on time or in advance 100%,we nearly not delay clients’ delivery time.

7.After Sales Services: We continue to serve you after sales and will be responsible for quality problem. Please rest assured!

Sleeve Couplings Sleeve couplings transmit lower to moderate shear torques between linked equipment by means of elastic inserts with external splines mated to inside splines. The insert material is usually EPDM, Neoprene or Hytrel, and the insert can be a 1-piece or two-piece design and style. Reasonable eccentricity Torsional damping (vibration) Conclude float with minimum axial perform Reduced to moderate torque, basic-objective apps

Mechanical bending couplings take misalignment of steel surfaces by wobbling, rolling or sliding. All steel mechanical bending couplings require lubrication. Examples of mechanical bending couplings are gear, grid and roller chain couplings. Equipment couplings transmit the optimum torque and least diameter of any elastic coupling.

China supplier CZPT Customized Flexible Jaw Shaft Coupling, Jaw Star Coupling, Jaw Shaft Couplings with high quality

Product Description

Densen personalized adaptable jaw shaft coupling,jaw star coupling,jaw shaft couplings

| Solution Title | Densen personalized versatile jaw shaft coupling,jaw star coupling,jaw shaft couplings |

| DN mm | twelve~160mm |

| Rated Torque | 25~25000 N·m |

| Allowable speed | 15300~1500 N·m |

| Materials | 35CrMo/ZG270/forty five# metal/Aluminum alloy |

| Software | Widely utilized in metallurgy, mining, engineering and other fields. |

Items display

Characteristics:

one,Double-diaphragm and little axial opposite wheel sort CZPT is the patent solution produced by our manufacturing facility,the patent No. ZL.ninety nine 2 46247.9

2,With compact strcture, the adjustment potential,anti-inpact and vibration-absorbing etc qualities will be higher by 35%-forty% than these of solitary diaphragm opposite wheel variety.

3,Underneath unforeseen diaphragm breakage problems, the plum blossom condition flange can still transfer the torque ,the security home is good .

Firm Info

Tools

Application Circumstance

Typical scenario of diaphragm CZPT utilized to variable frequency velocity control gear

JMB sort CZPT is used to HangZhou Oilfield Thermal Electrical power Plant

In accordance to the needs of HangZhou Electric powered Power Corporation, HangZhou Oilfield Thermal Energy Plant need to dynamically change the power generation in accordance to the load of the power grid and marketplace need, and carry out the transformation of the frequency converter and the suction enthusiast. The motor was initially a 1600KW, 730RPM non-frequency variable velocity motor matched by HangZhou Motor Manufacturing unit. The speed control mode right after altering the frequency is manual manage. Push the button velocity to enhance 10RPM or drop 10RPM. The CZPT is still the first elastic decoupling coupling, and the elastic de-coupling CZPT soon after frequency conversion is frequently broken, which straight has an effect on the standard electrical power era.

It is discovered by means of analysis that in the process of frequency conversion speed regulation, the pin of the CZPT can not bear the inertia of the speed regulation procedure (the diameter of the fan impeller is 3.3 meters) and is reduce off, which has wonderful hurt to the motor and the supporter.

Later on, they switched to the JMB460 double-diaphragm wheel-type CZPT of our manufacturing facility (patent quantity: ZL.99246247.9). Right after 1 hour of damaging experiment and much more than 1 yr of procedure test, the products is running extremely well, and there is no Exchange the diaphragm. 12 models have been rebuilt and the procedure is in excellent situation.

Other Application Scenario

Spare parts

Packaging & Transport

Contact us

The roller chain coupling is made up of two radial sprocket hubs that mesh with a double pitch roller chain. Chain couplings are utilised for minimal to medium torque and pace apps. The meshing of the sprocket and chain transmits torque, and the related play accommodates angular, parallel and axial misalignment.

The roller chain coupling consists of two radial sprocket hubs that mesh with a double pitch roller chain. Chain couplings are utilised for reduced to medium torque and velocity programs. The meshing of the sprocket and chain transmits torque, and the related engage in accommodates angular, parallel and axial misalignment.

China Custom Transmission Parts Shaft CZPT Grid CZPT Size 1160t with Reasonable Price near me supplier

Product Description

Merchandise Description

We are the top top Chinese CZPT manufacturer, and are specializing in different substantial high quality coupling.

KASIN COUPLINGS:

one. Substance: the hub of the Couplings is Solid Iron,Solid metal,solid steel, the Elastomer is Rubber.

two. OEM and ODM are available.

3. Higher performance in transmission.

four. Finishing: The surface treatment is normally blackening.

5. Substantial good quality with aggressive cost.

six. Diverse versions appropriate for your distinct demands.

seven. Stock for diverse bore measurement on equally sides accessible.

eight. Application in vast range of environment.

nine. Swift and straightforward mounting and disassembly.

10. Resistant to oil and electrical insulation.

eleven. Equivalent clockwise and anticlockwise rotational attributes.

12. Tiny dimension, low bodyweight, large transmitted torque.

thirteen. It has good performance on compensating the misalignment.

fourteen.Function of couplings:free of charge of maintenance,straightforward construction and effortless to put in.

15.Software:Mainly used in the mining, metallurgical, cement, chemicals, construction, building resources, electric power, telecommunications, textiles, and transportation departments.

Associated Products

Roller Chain Coupling FCL Coupling Curved Jaw Coupling

Production

Applications:

Couplings are supplied in the industry’s biggest selection of stock bore/keyway combinations. These couplings need no lubrication and give highly dependable provider for light, medium, and large responsibility electrical motor and inside combustion energy transmission apps. Applications consist of energy transmission to industrial tools this sort of as pumps, equipment packing containers, compressors, blowers, mixers, and conveyors.

About Us

Kasin group was recognized in 1989, and its first item is casting CZPT trolley for electricity & free conveyor system. In 1995, CZPT obtained HangZhou Guoping Forging Manufacturing facility (LYGP), a marketer of forging bolts & nuts to energy & free line industry in china. With this acquisition, CZPT positioned alone as 1 of key elements suppliers of monorail and electricity & free conveyor system in china.

In 2005, H&H Corp., a professional manufacturer of massive measurement conveyor chain, was obtained a portion as sharehould by Kasin, and worked as export window to all over the world, specially bucket elevator chain, sugar mill chain, welded mill scaper chain.

In 2015, CZPT proven by itself equipment company/Kasin equipment(ZheJiang )Co.,Ltd., produced fleixible coupling, eg: FCL Coupling, HRC Coupling,NM Coupling, Curved Jaw Coupling, Chain CZPT andJaw Coupling.

Presently,Kasin is 1 of the biggest professional expert of Engineering Course Conveyor Chain, Fall Forged Rivetless Chain, Forged Chain, Sugar Mill Chain, Bucket Elevator Chain, Flexible Couplings and a hundred% to oversea marketplace, masking Japan, U.S. and Europ and so forth.

With the certification of ISO 9001 and GB/T 19001, CZPT provide leading high quality products at the affordable price, to CZPT circumstance in extended-phrases cooperation, adhering to the slogan: “First TIME, Every single TIME“.

Our mission is to offer optimum quality items at the very best attainable price. And in carrying out so, to supply an unmatched customer experience and to create client have faith in and satisfaction. Trustworthy, Quality, Productive, Building, Safety the 5 vital components constituting KASIN, which is the crucial motto for all of the CZPT personnel. Therefore, we maintain striving to construct a corporate method that is extremely appreciated and we hope that you proceed to pick and use CZPT goods with delight and pleasure.

Exhibition

Certificates

Our Services

one. The questions about the CZPT will be answered in 24 hrs.

two. Update the procession of manufacturing.

three. Our skilled engineer can response complex concerns,assist you remedy technical problems and help you pick the most suited product according to your requirment.

4. Warranty twelve months: Free replacement of defective items in twelve months.

Packing Specifics & Delivery

Interior Packing: Carton, Common export packing or According to customer’s necessity

Outer packing: wood instances or In accordance to customer’s prerequisite

FAQ

Q: Are you buying and selling firm or company ?

A: We are professionally manufacturer in China and possess ourself Forging & Casting-workshop, warmly welcome to visit our factory at any time.

Q: How extended is your shipping and delivery time?

A: Generally it is 5-ten days if the items are in stock. or it is fifteen-25 times if the goods are not in stock, it is in accordance to quantity.

Q: Do you provide samples ? is it free or additional ?

A: Of course, it is obtainable for CZPT to post sample for acceptance totally free of cost, nonetheless it truly is CZPT regulation: for new potentioal customer, sample is free of charge but consumer is responsilble for logistic price.

Q: What is your conditions of payment ?

A: one hundred%T/T Prior to shipment after examine properly

If you have an additional question, pls really feel free of charge to contact us as underneath:

Follows Us:

Kasin Industries(ZheJiang ) Co.,Ltd.

No.989,Guoshun Road, ZheJiang FengPu Industrial Park,

FengXian District, ZheJiang , P.R.China, 201400

Tel: 86~571-8822571/8822 0571 -57152031 Fax: 86~571-8822571/8822 0571 -57152030

Http://kasinchain

Chain couplings need periodic lubrication, based on the application. Lubrication is normally brushed on to the chain, and caps are used to assist keep the coupling lubricated.

Consisting of two radially slotted hubs and a serpentine spring metal band, the mesh coupling offers the torsional damping and flexibility of an elastomer, but with the strength of metal. Grid couplings transmit torque and modify for angular, parallel and axial misalignment from one hub to the other by oscillating and sliding tapered grids in the hub grooves. The mesh cross section is typically tapered for greater hub speak to and less difficult assembly. Lubrication is required because of to the motion amongst the get in touch with hub and the mesh metal elements.