Product Description

Product Description

Coupling Deatails

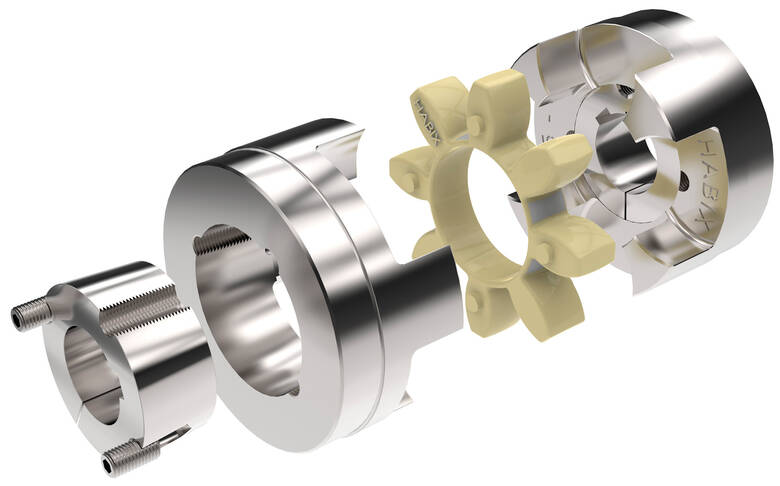

Name: High precision plum blossom

coupling Model: LM-Material: Aviation Aluminum Alloy

Working temperature: -40 ° C ~ 100 ° C

Support customization: Factory direct sales support customization.

Features:

1.Intermediate Elastomer Connection-Absorbs vibration, compensates for radial, angular, and axial 2.misalignment

3.Oil resistance and electrical insulation

4.Clockwise and counterclockwise rotation characteristics are identical-there are 3 different hardness 5.elastomer

6.Fixation by clamping screw.

|

Model parameter |

ΦD |

L |

LF |

LP |

F |

M |

Tightening screw torque |

|

(N.M) |

|||||||

|

GF-14X22 |

14 |

22 |

14.3 |

6.6 |

3.8 |

M 3 |

0.7 |

|

GF-20X25 |

20 |

25 |

16.7 |

8.6 |

4 |

M 3 |

0.7 |

|

GF-20X30 |

20 |

30 |

19.25 |

8.6 |

5.3 |

M 4 |

1.7 |

|

GF-25X30 |

25 |

30 |

20.82 |

11.6 |

5.6 |

M 4 |

1.7 |

|

GF-25X34 |

25 |

34 |

22.82 |

11.6 |

5.6 |

M 4 |

1.7 |

|

GF-30X35 |

30 |

35 |

23 |

11.5 |

5.75 |

M 4 |

1.7 |

|

GF-30X40 |

30 |

40 |

25.6 |

11.5 |

10 |

M 4 |

1.7 |

|

GF-40X50 |

40 |

50 |

32.1 |

14.5 |

10 |

M 5 |

4 |

|

GF-40X55 |

40 |

55 |

34.5 |

14.5 |

10 |

M 5 |

4 |

|

GF-40X66 |

40 |

66 |

40 |

14.5 |

12.75 |

M 5 |

4 |

|

GF-55X49 |

55 |

49 |

32 |

16.1 |

13.5 |

M 6 |

8.4 |

|

GF-55X78 |

55 |

78 |

46.4 |

16.1 |

15.5 |

M 6 |

8.4 |

|

GF-65X80 |

65 |

80 |

48.5 |

17.3 |

18.1 |

M 8 |

10.5 |

|

GF-65X90 |

65 |

90 |

53.5 |

17.3 |

18.1 |

M 8 |

10.5 |

Product Parameters

Detailed Photos

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Real-World Applications of Elastic Couplings

Elastic couplings find extensive use in various industries and applications where the reduction of vibration and shock is critical for performance, efficiency, and equipment longevity. Here are some examples:

- Industrial Machinery: Elastic couplings are commonly employed in industrial machinery such as pumps, compressors, conveyors, and generators. They help minimize vibration and shock, ensuring smooth and reliable operation while protecting sensitive components.

- Automotive Industry: In automotive applications, elastic couplings are used in drivetrains to dampen vibrations and shocks between the engine and the transmission. This enhances driving comfort, reduces noise, and prevents excessive wear on connected components.

- Power Generation: Power generation equipment, including turbines and generators, benefits from elastic couplings that absorb torsional vibrations and shocks. This aids in maintaining stable power output and extending the lifespan of critical components.

- Printing and Packaging: Printing presses and packaging machinery rely on elastic couplings to reduce vibrations during high-speed operations. This ensures precise printing and packaging while preventing damage to sensitive components.

- Robotics and Automation: Elastic couplings are crucial in robotics and automation systems to mitigate vibrations and shocks that can affect accuracy and reliability. They enable precise movement control and consistent performance.

- Medical Equipment: Medical devices such as MRI machines and X-ray equipment utilize elastic couplings to minimize vibrations that could impact image quality and precision during medical procedures.

These examples highlight how elastic couplings contribute to optimal performance, reduced maintenance, and increased equipment lifespan across diverse industries.

Maintaining the Longevity of Elastic Couplings

Ensuring the longevity and optimal performance of elastic couplings requires proper maintenance and care. Here are some key considerations:

- Regular Inspection: Periodically inspect the coupling for signs of wear, damage, or misalignment. Look for cracks, tears, or other deformations in the elastic elements.

- Lubrication: Some elastic couplings require lubrication for smooth operation. Follow the manufacturer’s guidelines on lubrication intervals and recommended lubricants.

- Environmental Conditions: Consider the operating environment of the coupling. Extreme temperatures, chemicals, moisture, and other factors can affect the coupling’s lifespan. Choose materials and designs suitable for the specific conditions.

- Proper Alignment: Ensure that the connected components are properly aligned to minimize excessive stress on the coupling. Misalignment can accelerate wear and reduce performance.

- Load Capacity: Do not exceed the coupling’s recommended torque and load ratings. Overloading the coupling can lead to premature failure.

- Shock and Vibration: If the system experiences frequent shock or vibration, consider using dampening or vibration-absorbing components to reduce the stress on the coupling.

- Replacement: When signs of wear or damage become noticeable, promptly replace the coupling to avoid further issues. Delaying replacement can lead to more significant problems in the machinery system.

- Follow Manufacturer Guidelines: Always follow the manufacturer’s recommendations for installation, operation, and maintenance of the specific coupling model.

By adhering to these considerations and performing regular maintenance tasks, engineers can extend the lifespan of elastic couplings and ensure reliable and efficient operation in various machinery applications.

Difference Between Elastic Coupling and Rigid Coupling

Elastic couplings and rigid couplings are two distinct types of couplings used in mechanical designs:

Elastic Coupling: An elastic coupling incorporates an elastomeric material, such as rubber, to provide flexibility and absorb shock and vibration. It allows for misalignment compensation and is ideal for applications where there may be slight misalignment or the need for vibration damping. Elastic couplings are commonly used in machinery that requires smooth operation and reduced stress on connected components.

Rigid Coupling: A rigid coupling, as the name suggests, is designed to provide a solid connection between two shafts. It does not have any flexible or damping elements and is used when precise alignment and torque transmission are critical. Rigid couplings are often used in applications where shafts need to maintain a constant alignment, such as in precision machines and systems with high torque requirements.

The choice between an elastic coupling and a rigid coupling depends on the specific requirements of the mechanical system, including the degree of misalignment, vibration levels, torque transmission, and the overall performance objectives.

editor by CX 2024-05-15

China supplier CNC Aluminum Elastic Rubber Spider Jaw Shaft Coupler GF14*22 20*25 25*30 40*50 Shaft Flexible Coupling Ball Screw Plum Coupling

Product Description

Product Description

Coupling Deatails

Name: High precision plum blossom

coupling Model: LM-Material: Aviation Aluminum Alloy

Working temperature: -40 ° C ~ 100 ° C

Support customization: Factory direct sales support customization.

Features:

1.Intermediate Elastomer Connection-Absorbs vibration, compensates for radial, angular, and axial 2.misalignment

3.Oil resistance and electrical insulation

4.Clockwise and counterclockwise rotation characteristics are identical-there are 3 different hardness 5.elastomer

6.Fixation by clamping screw.

|

Model parameter |

ΦD |

L |

LF |

LP |

F |

M |

Tightening screw torque |

|

(N.M) |

|||||||

|

GF-14X22 |

14 |

22 |

14.3 |

6.6 |

3.8 |

M 3 |

0.7 |

|

GF-20X25 |

20 |

25 |

16.7 |

8.6 |

4 |

M 3 |

0.7 |

|

GF-20X30 |

20 |

30 |

19.25 |

8.6 |

5.3 |

M 4 |

1.7 |

|

GF-25X30 |

25 |

30 |

20.82 |

11.6 |

5.6 |

M 4 |

1.7 |

|

GF-25X34 |

25 |

34 |

22.82 |

11.6 |

5.6 |

M 4 |

1.7 |

|

GF-30X35 |

30 |

35 |

23 |

11.5 |

5.75 |

M 4 |

1.7 |

|

GF-30X40 |

30 |

40 |

25.6 |

11.5 |

10 |

M 4 |

1.7 |

|

GF-40X50 |

40 |

50 |

32.1 |

14.5 |

10 |

M 5 |

4 |

|

GF-40X55 |

40 |

55 |

34.5 |

14.5 |

10 |

M 5 |

4 |

|

GF-40X66 |

40 |

66 |

40 |

14.5 |

12.75 |

M 5 |

4 |

|

GF-55X49 |

55 |

49 |

32 |

16.1 |

13.5 |

M 6 |

8.4 |

|

GF-55X78 |

55 |

78 |

46.4 |

16.1 |

15.5 |

M 6 |

8.4 |

|

GF-65X80 |

65 |

80 |

48.5 |

17.3 |

18.1 |

M 8 |

10.5 |

|

GF-65X90 |

65 |

90 |

53.5 |

17.3 |

18.1 |

M 8 |

10.5 |

Product Parameters

Detailed Photos

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Reducing Vibration and Shock in Machinery with Elastic Couplings

Elastic couplings play a crucial role in minimizing vibration and shock in machinery by offering flexibility and damping characteristics. Here’s how they contribute to this important function:

- Vibration Absorption: Elastic couplings are designed with flexible elements that can absorb and dampen vibrations generated by rotating machinery. These flexible elements act as shock absorbers, reducing the transmission of vibrations to other parts of the system.

- Isolation: The inherent flexibility of elastic couplings isolates vibrations and shocks from one side of the coupling to the other. This prevents vibrations from propagating throughout the connected components, helping to protect sensitive equipment and improve overall system performance.

- Resonance Damping: Elastic couplings can help dampen resonance frequencies that can occur in machinery during operation. By absorbing and dissipating energy, they reduce the risk of resonance-related issues that can lead to mechanical failure or decreased efficiency.

- Smooth Torque Transmission: Elastic couplings offer a smooth torque transmission that helps reduce sudden torque spikes and shocks during start-up or sudden load changes. This prevents abrupt mechanical stresses that can lead to vibration and shock propagation.

- Increased Equipment Lifespan: By minimizing the impact of vibrations and shocks, elastic couplings contribute to the longevity of connected machinery and components. Reduced vibration-related wear and tear can extend the service life of the entire system.

Overall, elastic couplings are effective tools for managing vibration and shock in machinery, enhancing operational reliability, reducing maintenance needs, and maintaining optimal performance.

Installation Guidelines for Integrating Elastic Couplings

Proper installation of elastic couplings is essential to ensure their optimal performance and longevity. Engineers should follow these guidelines:

1. Alignment: Before installation, ensure that the connected shafts are properly aligned within the manufacturer’s specified tolerances. Misalignment can lead to premature wear and reduced coupling effectiveness.

2. Lubrication: Some elastic couplings require lubrication to maintain smooth operation. Follow the manufacturer’s recommendations for the type and amount of lubricant to use.

3. Mounting: Securely mount the elastic coupling onto the shafts using appropriate torque values for the coupling’s fasteners. Use a torque wrench to prevent over-tightening, which can damage the coupling or the shafts.

4. Inspection: Inspect the coupling for any signs of damage or defects before installation. Any issues should be addressed before the coupling is put into operation.

5. Clearance: Maintain proper clearance between the coupling and surrounding components to prevent interference during operation, especially if the coupling flexes during use.

6. Environmental Factors: Consider the operating environment, such as temperature, humidity, and exposure to chemicals, when selecting an appropriate elastic coupling material.

7. Manufacturer’s Recommendations: Always refer to the manufacturer’s installation guidelines and instructions specific to the type and model of elastic coupling being used.

Following these installation guidelines will help ensure the effective and safe integration of elastic couplings into mechanical systems.

Industries Using Elastic Couplings

Elastic couplings find extensive use in various industries due to their unique benefits:

- Industrial Manufacturing: Elastic couplings are widely used in manufacturing equipment, conveyors, and assembly lines to maintain smooth operation and reduce vibrations.

- Automotive: Automotive applications include engine components, powertrain systems, and vehicle suspension systems where flexibility and vibration dampening are crucial.

- Power Generation: Elastic couplings are used in power generation equipment such as generators, turbines, and pumps to absorb torsional vibrations and enhance efficiency.

- Aerospace: In aerospace applications, elastic couplings help dampen vibrations in critical components like aircraft engines and control systems.

- Renewable Energy: Wind turbines and solar tracking systems benefit from elastic couplings to accommodate misalignments and vibrations caused by changing wind conditions.

- Mining: Mining equipment such as crushers, conveyors, and screens utilize elastic couplings to handle varying loads and minimize shock loads.

- Marine: Elastic couplings are used in marine propulsion systems and ship equipment to manage torque fluctuations and reduce vibrations.

These industries rely on elastic couplings to enhance performance, extend machinery lifespan, and minimize downtime due to vibrations, misalignments, and shock loads.

editor by CX 2024-05-07

China high quality Aluminum alloy elastic shaft couplings screw couplings flexible shaft couplings with Good quality

Warranty: 1 Yr

Applicable Industries: Constructing Substance Outlets, Producing Plant, Machinery Restore Stores, Printing Shops, Building works , Strength & Mining

Tailored support: OEM

Versatile or Rigid: Flexible

Common or Nonstandard: Regular

Material: Stainless Metal, Metal

Coloration: grey

MOQ: 2pcs

Characteristic: Higher Precision

Packaging Specifics: paper box

Merchandise Description

| Name | Elastic Couplings Aluminum Alloy Elastic Shaft Couplings Screw Couplings |

| Material | Stainless Steel, Steel |

| colour | grey |

| Features | High Accuracy |

| Application industry | Building Content Retailers, Producing Plant, Machinery Fix Stores, Printing Outlets, Building performs , Vitality & Mining |

| Post-warranty services | 1 Yr |

Worm Shafts and Gearboxes

If you have a gearbox, you may be wondering what the best Worm Shaft is for your application. There are several things to consider, including the Concave shape, Number of threads, and Lubrication. This article will explain each factor and help you choose the right Worm Shaft for your gearbox. There are many options available on the market, so don’t hesitate to shop around. If you are new to the world of gearboxes, read on to learn more about this popular type of gearbox.

Concave shape

The geometry of a worm gear varies considerably depending on its manufacturer and its intended use. Early worms had a basic profile that resembled a screw thread and could be chased on a lathe. Later, tools with a straight sided g-angle were developed to produce threads that were parallel to the worm’s axis. Grinding was also developed to improve the finish of worm threads and minimize distortions that occur with hardening.

To select a worm with the proper geometry, the diameter of the worm gear must be in the same unit as the worm’s shaft. Once the basic profile of the worm gear is determined, the worm gear teeth can be specified. The calculation also involves an angle for the worm shaft to prevent it from overheating. The angle of the worm shaft should be as close to the vertical axis as possible.

Double-enveloping worm gears, on the other hand, do not have a throat around the worm. They are helical gears with a straight worm shaft. Since the teeth of the worm are in contact with each other, they produce significant friction. Unlike double-enveloping worm gears, non-throated worm gears are more compact and can handle smaller loads. They are also easy to manufacture.

The worm gears of different manufacturers offer many advantages. For instance, worm gears are one of the most efficient ways to increase torque, while lower-quality materials like bronze are difficult to lubricate. Worm gears also have a low failure rate because they allow for considerable leeway in the design process. Despite the differences between the two standards, the overall performance of a worm gear system is the same.

The cone-shaped worm is another type. This is a technological scheme that combines a straight worm shaft with a concave arc. The concave arc is also a useful utility model. Worms with this shape have more than three contacts at the same time, which means they can reduce a large diameter without excessive wear. It is also a relatively low-cost model.

Thread pattern

A good worm gear requires a perfect thread pattern. There are a few key parameters that determine how good a thread pattern is. Firstly, the threading pattern must be ACME-threaded. If this is not possible, the thread must be made with straight sides. Then, the linear pitch of the “worm” must be the same as the circular pitch of the corresponding worm wheel. In simple terms, this means the pitch of the “worm” is the same as the circular pitch of the worm wheel. A quick-change gearbox is usually used with this type of worm gear. Alternatively, lead-screw change gears are used instead of a quick-change gear box. The pitch of a worm gear equals the helix angle of a screw.

A worm gear’s axial pitch must match the circular pitch of a gear with a higher axial pitch. The circular pitch is the distance between the points of teeth on the worm, while the axial pitch is the distance between the worm’s teeth. Another factor is the worm’s lead angle. The angle between the pitch cylinder and worm shaft is called its lead angle, and the higher the lead angle, the greater the efficiency of a gear.

Worm gear tooth geometry varies depending on the manufacturer and intended use. In early worms, threading resembled the thread on a screw, and was easily chased using a lathe. Later, grinding improved worm thread finishes and minimized distortions from hardening. As a result, today, most worm gears have a thread pattern corresponding to their size. When selecting a worm gear, make sure to check for the number of threads before purchasing it.

A worm gear’s threading is crucial in its operation. Worm teeth are typically cylindrical, and are arranged in a pattern similar to screw or nut threads. Worm teeth are often formed on an axis of perpendicular compared to their parallel counterparts. Because of this, they have greater torque than their spur gear counterparts. Moreover, the gearing has a low output speed and high torque.

Number of threads

Different types of worm gears use different numbers of threads on their planetary gears. A single threaded worm gear should not be used with a double-threaded worm. A single-threaded worm gear should be used with a single-threaded worm. Single-threaded worms are more effective for speed reduction than double-threaded ones.

The number of threads on a worm’s shaft is a ratio that compares the pitch diameter and number of teeth. In general, worms have 1,2,4 threads, but some have three, five, or six. Counting thread starts can help you determine the number of threads on a worm. A single-threaded worm has fewer threads than a multiple-threaded worm, but a multi-threaded worm will have more threads than a mono-threaded planetary gear.

To measure the number of threads on a worm shaft, a small fixture with two ground faces is used. The worm must be removed from its housing so that the finished thread area can be inspected. After identifying the number of threads, simple measurements of the worm’s outside diameter and thread depth are taken. Once the worm has been accounted for, a cast of the tooth space is made using epoxy material. The casting is moulded between the two tooth flanks. The V-block fixture rests against the outside diameter of the worm.

The circular pitch of a worm and its axial pitch must match the circular pitch of a larger gear. The axial pitch of a worm is the distance between the points of the teeth on a worm’s pitch diameter. The lead of a thread is the distance a thread travels in one revolution. The lead angle is the tangent to the helix of a thread on a cylinder.

The worm gear’s speed transmission ratio is based on the number of threads. A worm gear with a high ratio can be easily reduced in one step by using a set of worm gears. However, a multi-thread worm will have more than two threads. The worm gear is also more efficient than single-threaded gears. And a worm gear with a high ratio will allow the motor to be used in a variety of applications.

Lubrication

The lubrication of a worm gear is particularly challenging, due to its friction and high sliding contact force. Fortunately, there are several options for lubricants, such as compounded oils. Compounded oils are mineral-based lubricants formulated with 10 percent or more fatty acid, rust and oxidation inhibitors, and other additives. This combination results in improved lubricity, reduced friction, and lower sliding wear.

When choosing a lubricant for a worm shaft, make sure the product’s viscosity is right for the type of gearing used. A low viscosity will make the gearbox difficult to actuate and rotate. Worm gears also undergo a greater sliding motion than rolling motion, so grease must be able to migrate evenly throughout the gearbox. Repeated sliding motions will push the grease away from the contact zone.

Another consideration is the backlash of the gears. Worm gears have high gear ratios, sometimes 300:1. This is important for power applications, but is at the same time inefficient. Worm gears can generate heat during the sliding motion, so a high-quality lubricant is essential. This type of lubricant will reduce heat and ensure optimal performance. The following tips will help you choose the right lubricant for your worm gear.

In low-speed applications, a grease lubricant may be sufficient. In higher-speed applications, it’s best to apply a synthetic lubricant to prevent premature failure and tooth wear. In both cases, lubricant choice depends on the tangential and rotational speed. It is important to follow manufacturer’s guidelines regarding the choice of lubricant. But remember that lubricant choice is not an easy task.

editor by czh

China supplier CZPT Customized Flexible Oldham CZPT Set Screw Clamp Type Shaft CZPT for Servo Motor with Best Sales

Item Description

DDensen customized Flexible Oldham CZPT Established Screw Clamp Kind Shaft CZPT for Servo Motor

| Solution Title | Adaptable Oldham CZPT Established Screw Clamp Kind Shaft CZPT for Servo Motor |

| DN mm | 12~160mm |

| Rated Torque | 25~25000 N·m |

| Allowable speed | 15300~1500 N·m |

| Substance | 35CrMo/ZG270/forty five# steel/Aluminum alloy |

| Software | Widely utilised in metallurgy, mining, engineering and other fields. |

Product show

Company Data

Products

Standard case of diaphragm CZPT applied to variable frequency pace control products

JMB kind CZPT is utilized to HangZhou Oilfield Thermal Power Plant

According to the specifications of HangZhou Electric Electrical power Company, HangZhou Oilfield Thermal Electrical power Plant must dynamically change the energy generation in accordance to the load of the electrical power grid and market need, and have out the transformation of the frequency converter and the suction fan. The motor was at first a 1600KW, 730RPM non-frequency variable velocity motor matched by HangZhou Motor Manufacturing facility. The velocity manage method after modifying the frequency is manual manage. Push the button pace to boost 10RPM or drop 10RPM. The CZPT is still the authentic elastic decoupling coupling, and the elastic de-coupling CZPT after frequency conversion is often ruined, which immediately affects the typical electricity generation.

It is identified by means of investigation that in the procedure of frequency conversion velocity regulation, the pin of the CZPT can not bear the inertia of the speed regulation method (the diameter of the enthusiast impeller is 3.3 meters) and is cut off, which has fantastic hurt to the motor and the fan.

Afterwards, they switched to the JMB460 double-diaphragm wheel-variety CZPT of our manufacturing unit (patent number: ZL.99246247.9). Following 1 hour of damaging experiment and a lot more than 1 calendar year of operation check, the tools is operating very effectively, and there is no Replace the diaphragm. 12 models have been rebuilt and the procedure is in great condition.

Other Application Circumstance

Spare parts

Packaging & Shipping and delivery

Speak to us

Couplings slide into two wide groups: substance bending and mechanical bending. Versatile content types gain flexibility by stretching or compressing elastic components this sort of as rubber or bending slim metallic discs or meshes. Content elastic couplings do not call for lubrication, apart from for mesh couplings. Mechanical flex couplings accept misalignment caused by wobbling, rolling, or sliding of metallic surfaces. All steel mechanical flexible couplings require lubrication.

Diaphragm Couplings Diaphragm couplings use a one or a series of plates or diaphragms as adaptable components. It transfers torque from the outer diameter of the flex plate to the inner diameter, by means of the spool or spacer, and then from the internal diameter to the outer diameter. When the diaphragm is subjected to misalignment, the outer diameter is deflected relative to the interior diameter. For instance, axial displacement makes an attempt to stretch the diaphragm, which outcomes in a combination of elongation and bending of the diaphragm profile. Angular, parallel and higher axial misalignment permitted Excellent for large torque, higher speed programs

One-Piece Shaft Direct Connection Two Stage Screw Air Compressor

One-piece shaft direct link two phase screw CZPT

Two stage compression characteristics and positive aspects:

1.The intaked air stream right after compressed by the very first phase compression, connect with massive amount oil mist in the cooling channel then awesome quickly, and then goes into the next stage compression program to be compressed and discharged beneath the necessity pressure, a lot a lot more energy preserving than one phase compression sort.

two. Undertake German double rotor screw air conclude, large rotor and reduced rotary pace developing, the initial and the second phase compression rotors are made in a single compression chamber, via various driving gear and pushed equipment ratio to get the very best seal velocity of the 1st phase and the 2nd stage rotors equipment top line, tremendously enhancing the air stop compression effectiveness.

3. Undertake interior spray oil cooling variety, enable air isothermal compression, saving vitality by eight%.

three. Every single stage compression ratio is as minimal as 3:1, little interior leakage, enhancing efficiency by15%.

Scaled-down compression ratio can increase managing steadiness and dependability, substantial efficiency functioning, long making use of existence, extremely reduced fault rate.

4. The entire unit device can reach China national level-1 power effectiveness common.

five. Have fastened speed kind (TKL) and long lasting magnetic frequency conversion motor one particular-piece shaft kind (TKLYC).

I. TKL series of two phase compression twin screw CZPT

Undertake CZPTd twin rotor screw air end imported from German and Italy, rate of five:6, large precision of gear and seal, use SKF bearing and substantial grade oil seals to ensure the principal engine long existence and low sound procedure. The air finish and the diesel / electrical motor is immediately connected through the high elastic coupling, no gear, significantly less strength use, a lot more air output, higher reliability, lengthy support existence and lower maintenance value.

II. TKLYC series of Permanent magnetic frequency conversion two phase compression twin screw CZPT

Undertake energy preserving permanent magnetic frequency conversion screw air finish:

one. Adopt 1-piece shaft relationship framework for the everlasting magnetic motor and the air end

★Permanent magnetic Motor’s rotor is directly sleeved on shaft of the air stop, embedded built-in immediate-connecting structure, CZPT coupling portion or transmission gear component, particularly one particular-piece shaft, making sure of one hundred% transmission efficiency.

★Taper link is adopted for motor, and it can be assembled and disassembled quite simply.

2. Undertake everlasting magnetic frequency conversion electric motor

★Permanent magnetic frequency conversion motor is the most CZPTd technological electric motor, effectiveness can be up to 97%, larger by 3%-5% than common motor with frequency conversion system type, preserving power a good deal obviously.

★Permanent magnetic electrical motor adopts large temperature resistance exceptional earth permanent magnet to make sure no demagnetization. Without motor bearing or sleeve, so no need to have lubricating grease, no require concern alignment dilemma, compact construction, saving room, practical use and upkeep.

three. Broad frequency conversion, consistent strain air feeding

★Frequency software scope (0HZ-200HZ) is broad, and motor efficiency under various load is essentially consistent.

★The motor is large torque, robust adaptability and loaded startup.

★The total equipment work under frequency conversion state, and can run frequency modulation according to the client’s true need of air use at continual force, realizing higher effectiveness and power preserving.

4. Operating stable and reliable

★CZPT starting up beneath frequency conversion condition, tremendously minimizing the impacting to the electricity grid products, steering clear of of harm to the electric tools and conserving electric power when beginning.

★No want to set operating strain up and bottom limit value, can run by regulating the frequency at the placing stress point to stabilize the pressure, so can conserve electric strength by ten%-fifteen%.

five. CZPT saving a whole lot certainly

Compared with the mounted velocity sort compressor, our permanent magnetic frequency conversion compressor can conserve power by 30% when compared with the normal motor with frequency device variety compressor, our compressor can save energy by 5%-10%.

CZPT parameter of two stage CZPT (TKLYC sort):

| Variety | Exhause force (Mpa) | Air displacemen (m3/min) | Electricity (Kw) | Noise (dBa) | Dimensions (mm) | Outlet pipe dimension | Weight (Kg) |

| TKLYC-15F-II | .8/1./one.three | two.7/2.3/two.2 | fifteen | 66 | 1600*900*1300 | G1 1/two | 800 |

| TKLYC-18F-II | .8/1./1.three | 3.five/3./2.five | 18.five | sixty six | 1600*900*1300 | G1 1/2 | 840 |

| TKLYC-22F-II | .8/1./1.three | 4./3.5/three. | 22 | sixty six | 1600*900*1300 | G1 one/2 | 860 |

| TKLYC-30F-II | .eight/1./one.3 | 6.4/five./four.2 | thirty | sixty eight | 1800*1500*1510 | G1 1/2 | 1100 |

| TKLYC-37F-II | .eight/1./one.3 | seven./6./five.five | 37 | sixty eight | 1800*1500*1510 | G1 1/two | 1100 |

| TKLYC-45F-II | .eight/1./1.three | nine.five/8.8/8.one | 45 | sixty eight | 1800*1500*1510 | DN50 | 2200 |

| TKLYC-55F-II | .8/1./one.three | eleven.5/ten.nine/10.5 | fifty five | 68 | 2300*1400*1800 | DN50 | 2600 |

| TKLYC-75F-II | .8/one./1.3 | 16.one/14.5/twelve.five | 75 | sixty eight | 2300*1400*1800 | DN65 | 2850 |

| TKLYC-90F-II | .eight/one./1.three | 19.eight/16.five/13.five | 90 | sixty eight | 2470*1700*2571 | DN65 | 2950 |

| TKLYC-110F-II | .8/1./one.three | 24./19.eight/seventeen.2 | one hundred ten | 68 | 3100*1740*2150 | DN80 | 3000 |

| TKLYC-132F-II | .8/one./1.3 | 28.three/23.2/19.two | 132 | 70 | 3100*1740*2150 | DN80 | 3100 |

| TKLYC-160F-II | .8/1./one.3 | 33.3/28.four/23.six | a hundred and sixty | seventy two | 3460*2040*2200 | DN80 | 5400 |

| TKLYC-185F-II | .8/1./1.three | 38.5/33.3/28.four | 185 | 72 | 3460*2040*2200 | DN80 | 5600 |

| TKLYC-200F-II | .eight/one./one.3 | forty one.3/38.five/33.5 | 200 | 75 | 3460*2040*2200 | DN80 | 5800 |

| TKLYC-220F-II | .eight/1./one.3 | forty five.5/forty.8/37.six | 220 | seventy five | 3720*2220*2200 | DN100 | 6100 |

| TKLYC-250F-II | .8/one./1.3 | 54.seven/forty four.9/40.3 | 250 | seventy five | 3720*2220*2200 | DN100 | 6200 |

CZPT parameter of two phase CZPT (TKL sort):

| Model | Exhause strain (Mpa) | Air displacement (m3/min) | Electricity (Kw) | Sound (dBa) | Proportions (mm) | Outlet pipe dimensions | Excess weight (Kg) |

| TKL-45F-II | .8 | 9.five | 45 | 68 | 1800*1500*1510 | DN50 | 2400 |

| one. | 8.eight | ||||||

| 1.3 | eight.1 | ||||||

| TKL-55F-II | .8 | eleven.five | fifty five | sixty eight | 1800*1500*1510 | DN50 | 2430 |

| one. | ten.nine | ||||||

| one.three | 10.5 | ||||||

| TKL-75F-II | .8 | 16.one | seventy five | sixty eight | 2470*1700*2571 | DN65 | 2700 |

| 1. | fourteen.5 | ||||||

| 1.three | twelve.five | ||||||

| TKL-90F-II | .eight | 19.eight | ninety | sixty eight | 2470*1700*2571 | DN65 | 2800 |

| 1. | 16.five | ||||||

| 1.three | thirteen.five | ||||||

| TKL-110F-II | .8 | 24. | 110 | 68 | 2660*1700*2571 | DN65 | 2850 |

| 1. | 19.eight | ||||||

| 1.three | 17.two | ||||||

| TKL-132F-II | .eight | 28.three | 132 | 70 | 2660*1700*2571 | DN65 | 4150 |

| one. | 23.2 | ||||||

| 1.three | 19.2 | ||||||

| TKL-160F-II | .eight | 33.three | 160 | 72 | 3460*2040*2200 | DN80 | 5100 |

| one. | 28.four | ||||||

| one.3 | 23.six | ||||||

| TKL-185F-II | .eight | 38.five | 185 | 72 | 3460*2040*2200 | DN80 | 5200 |

| one. | 33.three | ||||||

| one.three | 28.four | ||||||

| TKL-200F-II | .eight | forty one.three | 200 | seventy five | 3460*2040*2200 | DN80 | 5250 |

| 1. | 38.five | ||||||

| 1.3 | 33.five | ||||||

| TKL-220F-II | .eight | forty five.5 | 220 | seventy five | 3720*2220*2200 | DN100 | 6100 |

| 1. | 40.eight | ||||||

| one.three | 37.six | ||||||

| TKL-250F-II | .eight | fifty four.seven | 250 | 75 | 3720*2220*2200 | DN100 | 6200 |

| 1. | forty four.nine | ||||||

| 1.3 | 40.three |

Our manufacturing unit and workshop

Soon after income services:

1. Providing professional air compression system creating for totally free.

2. Offering our manufacturing facility original device components at most affordable price tag soon after machine product sales.

three. Providing training and direction for free, clients can send their workers to our manufacturing unit to understand how to run the machines.

four. Warranty period: the screw principal equipment is 1 calendar year, the bearing is 1 yr, the wear areas of air ingestion valve, electrical elements, electromagnetic valve, fee valve are 6 months

5. The air filter, oil filter, oil-drinking water separator, lubricating oil, rubber areas and and so on. are not included in warranty variety.

Certification and patents of our CZPT

FAQ:

Q1: Are you manufacturing facility or trade organization?

A1: We are manufacturing facility.

Q2: Warranty conditions of your equipment?

A2: One yr warranty for the device and technological help according to your needs.

Q3: Will you give some spare parts of the devices?

A3: Yes, of course.

This autumn: How lengthy will you consider to prepare creation?

A4: 380V 50HZ we can delivery the goods inside twenty days. Other electrical energy or other colour we will shipping inside 30 times.

Q5: Can you accept OEM orders?

A5: Yes, with professional design team, OEM orders are highly welcome!

One-Piece Shaft Direct Connection Rotary Screw Air Compressor

One-piece shaft immediate link rotary screw CZPT

Two stage compression features and advantages:

one.The intaked air movement following compressed by the initial stage compression, connect with big quantity oil mist in the cooling channel then cool rapidly, and then goes into the 2nd stage compression method to be compressed and discharged beneath the requirement strain, significantly far more strength saving than one phase compression type.

two. Adopt German double rotor screw air finish, large rotor and low rotary speed designing, the initial and the 2nd stage compression rotors are created in one particular compression chamber, via distinct driving gear and driven gear ratio to get the greatest seal pace of the initial phase and the second stage rotors gear leading line, tremendously enhancing the air finish compression efficiency.

three. Undertake inside spray oil cooling type, allow air isothermal compression, preserving power by 8%.

three. Each and every phase compression ratio is as lower as three:one, small inner leakage, strengthening effectiveness by15%.

Smaller sized compression ratio can boost managing stability and trustworthiness, large effectiveness functioning, prolonged employing existence, extremely lower fault rate.

four. The entire unit device can achieve China countrywide stage-1 strength efficiency standard.

5. Have mounted pace type (TKL) and long term magnetic frequency conversion motor 1-piece shaft type (TKLYC).

I. TKL collection of two stage compression twin screw CZPT

Undertake CZPTd twin rotor screw air end imported from German and Italy, charge of five:6, large precision of equipment and seal, use SKF bearing and high quality oil seals to make sure the major engine long daily life and lower sound procedure. The air stop and the diesel / electric powered motor is straight related by means of the higher elastic coupling, no equipment, considerably less power consumption, more air output, high dependability, prolonged support existence and reduced maintenance cost.

II. TKLYC collection of Permanent magnetic frequency conversion two phase compression twin screw CZPT

Adopt energy saving long term magnetic frequency conversion screw air conclude:

one. Undertake A single-piece shaft link composition for the everlasting magnetic motor and the air stop

★Permanent magnetic Motor’s rotor is straight sleeved on shaft of the air conclude, embedded integrated immediate-connecting structure, CZPT coupling portion or transmission gear component, particularly 1-piece shaft, making sure of a hundred% transmission efficiency.

★Taper relationship is adopted for motor, and it can be assembled and disassembled extremely simply.

2. Adopt long lasting magnetic frequency conversion electrical motor

★Permanent magnetic frequency conversion motor is the most CZPTd technical electric powered motor, efficiency can be up to 97%, increased by 3%-five% than regular motor with frequency conversion system type, conserving vitality a whole lot obviously.

★Permanent magnetic electric powered motor adopts higher temperature resistance exceptional earth long lasting magnet to make sure no demagnetization. Without having motor bearing or sleeve, so no need lubricating grease, no need to have issue alignment difficulty, compact composition, saving room, handy use and servicing.

three. Broad frequency conversion, consistent stress air feeding

★Frequency application scope (0HZ-200HZ) is extensive, and motor performance under distinct load is essentially consistent.

★The motor is big torque, robust adaptability and loaded startup.

★The complete device operate underneath frequency conversion point out, and can run frequency modulation in accordance to the client’s real prerequisite of air consumption at consistent stress, acknowledging high effectiveness and vitality conserving.

4. Running steady and reputable

★CZPT starting up beneath frequency conversion condition, drastically reducing the impacting to the energy grid equipment, steering clear of of hurt to the electrical products and preserving electrical vitality when starting.

★No require to set operating stress up and bottom limit value, can work by regulating the frequency at the setting force position to stabilize the pressure, so can preserve electric strength by ten%-fifteen%.

five. CZPT saving a lot obviously

Compared with the fastened velocity kind compressor, our everlasting magnetic frequency conversion compressor can preserve energy by 30% in comparison with the ordinary motor with frequency device type compressor, our compressor can conserve strength by five%-10%.

CZPT parameter of two stage CZPT (TKLYC variety):

| Sort | Exhause force (Mpa) | Air displacemen (m3/min) | Electricity (Kw) | Noise (dBa) | Dimensions (mm) | Outlet pipe size | Bodyweight (Kg) |

| TKLYC-15F-II | .eight/1./1.three | 2.7/two.three/2.2 | 15 | sixty six | 1600*900*1300 | G1 1/2 | 800 |

| TKLYC-18F-II | .eight/one./1.3 | 3.5/three./two.5 | eighteen.5 | 66 | 1600*900*1300 | G1 1/two | 840 |

| TKLYC-22F-II | .8/1./1.3 | four./three.five/three. | 22 | sixty six | 1600*900*1300 | G1 one/two | 860 |

| TKLYC-30F-II | .eight/1./1.3 | 6.4/5./4.two | thirty | 68 | 1800*1500*1510 | G1 one/two | 1100 |

| TKLYC-37F-II | .eight/one./one.three | seven./six./5.five | 37 | sixty eight | 1800*1500*1510 | G1 1/2 | 1100 |

| TKLYC-45F-II | .8/1./1.three | nine.five/8.8/eight.1 | 45 | sixty eight | 1800*1500*1510 | DN50 | 2200 |

| TKLYC-55F-II | .8/1./1.3 | 11.5/10.9/10.five | fifty five | 68 | 2300*1400*1800 | DN50 | 2600 |

| TKLYC-75F-II | .8/1./one.3 | 16.one/fourteen.5/12.five | 75 | 68 | 2300*1400*1800 | DN65 | 2850 |

| TKLYC-90F-II | .8/1./one.3 | 19.8/16.5/thirteen.5 | 90 | sixty eight | 2470*1700*2571 | DN65 | 2950 |

| TKLYC-110F-II | .eight/one./1.three | 24./19.8/seventeen.two | one hundred ten | 68 | 3100*1740*2150 | DN80 | 3000 |

| TKLYC-132F-II | .8/one./one.three | 28.three/23.2/19.two | 132 | 70 | 3100*1740*2150 | DN80 | 3100 |

| TKLYC-160F-II | .8/one./one.3 | 33.3/28.four/23.six | 160 | 72 | 3460*2040*2200 | DN80 | 5400 |

| TKLYC-185F-II | .8/1./1.3 | 38.five/33.3/28.four | 185 | 72 | 3460*2040*2200 | DN80 | 5600 |

| TKLYC-200F-II | .eight/one./one.three | forty one.3/38.five/33.5 | 200 | seventy five | 3460*2040*2200 | DN80 | 5800 |

| TKLYC-220F-II | .8/1./one.3 | 45.5/forty.8/37.6 | 220 | seventy five | 3720*2220*2200 | DN100 | 6100 |

| TKLYC-250F-II | .8/1./one.three | fifty four.7/forty four.nine/forty.three | 250 | 75 | 3720*2220*2200 | DN100 | 6200 |

CZPT parameter of two phase CZPT (TKL type):

| Model | Exhause pressure (Mpa) | Air displacement (m3/min) | Energy (Kw) | Sound (dBa) | Proportions (mm) | Outlet pipe dimension | Bodyweight (Kg) |

| TKL-45F-II | .eight | 9.five | 45 | sixty eight | 1800*1500*1510 | DN50 | 2400 |

| one. | 8.eight | ||||||

| one.three | 8.one | ||||||

| TKL-55F-II | .eight | 11.5 | 55 | 68 | 1800*1500*1510 | DN50 | 2430 |

| one. | 10.nine | ||||||

| one.3 | ten.5 | ||||||

| TKL-75F-II | .8 | 16.one | seventy five | sixty eight | 2470*1700*2571 | DN65 | 2700 |

| one. | fourteen.5 | ||||||

| 1.3 | twelve.5 | ||||||

| TKL-90F-II | .eight | 19.8 | 90 | sixty eight | 2470*1700*2571 | DN65 | 2800 |

| one. | 16.five | ||||||

| one.3 | 13.5 | ||||||

| TKL-110F-II | .eight | 24. | one hundred ten | sixty eight | 2660*1700*2571 | DN65 | 2850 |

| one. | 19.eight | ||||||

| one.3 | 17.two | ||||||

| TKL-132F-II | .8 | 28.three | 132 | 70 | 2660*1700*2571 | DN65 | 4150 |

| one. | 23.two | ||||||

| 1.3 | 19.two | ||||||

| TKL-160F-II | .eight | 33.3 | a hundred and sixty | 72 | 3460*2040*2200 | DN80 | 5100 |

| one. | 28.4 | ||||||

| 1.3 | 23.six | ||||||

| TKL-185F-II | .8 | 38.5 | 185 | seventy two | 3460*2040*2200 | DN80 | 5200 |

| 1. | 33.3 | ||||||

| 1.three | 28.four | ||||||

| TKL-200F-II | .8 | 41.3 | two hundred | 75 | 3460*2040*2200 | DN80 | 5250 |

| one. | 38.5 | ||||||

| one.3 | 33.5 | ||||||

| TKL-220F-II | .8 | 45.five | 220 | 75 | 3720*2220*2200 | DN100 | 6100 |

| 1. | forty.8 | ||||||

| one.3 | 37.6 | ||||||

| TKL-250F-II | .eight | 54.seven | 250 | 75 | 3720*2220*2200 | DN100 | 6200 |

| 1. | forty four.nine | ||||||

| 1.three | 40.three |

Our manufacturing facility and workshop

Right after sales services:

1. Providing expert air compression program designing for free of charge.

two. Delivering our manufacturing facility original device components at most affordable price tag right after equipment sales.

3. Providing coaching and assistance for free of charge, consumers can send out their staff to our manufacturing facility to discover how to run the machines.

4. Warranty time period: the screw primary equipment is a single 12 months, the bearing is one particular yr, the use components of air intake valve, electric components, electromagnetic valve, rate valve are six months

five. The air filter, oil filter, oil-h2o separator, lubricating oil, rubber elements and etc. are not provided in warranty assortment.

Certification and patents of our CZPT

FAQ:

Q1: Are you manufacturing unit or trade company?

A1: We are manufacturing facility.

Q2: Warranty phrases of your machine?

A2: One yr warranty for the equipment and complex help according to your requirements.

Q3: Will you supply some spare components of the equipment?

A3: Yes, of program.

This fall: How extended will you just take to prepare production?

A4: 380V 50HZ we can shipping and delivery the goods inside of 20 times. Other electrical energy or other colour we will delivery inside 30 days.

Q5: Can you acknowledge OEM orders?

A5: Yes, with professional design team, OEM orders are highly welcome!

CNC Machined Shaft Wheel Molded-in Blind Threaded Inserts for Plastic, Brass Inserts Screw

CNC CZPTd Shaft Wheel Molded-in Blind Threaded Inserts for CZPT, Brass Inserts CZPT

Items Description

large top quality Flange and Slicing Hole brass insert

Quality CZPT: CZPT, TS16949, SGS

Location of Origin: HangCZPT, China

Fashion:Cylinder

Use: CZPT, aerospace

Wire Diameter: M1.~M6.

Surface Complete:white zinc

Load Kind: Flange and Reducing

| Material | Brass,Stainless Metal,Carbon metal,Aluminum alloy,in accordance to customer’s need |

| End | Zn/Ni/Tin/Au plating,Black Oxide,Anodizing and so on. |

| Insert Methods | By Ultrasonic,Heat staking,Insert Molding,Chilly push-in Techniques |

| Top quality Handle | Stick to Drawing Spec |

| Administration Program | CZPT:2008 |

| Certification | SGS,RoHS,Material Certication,PPAP |

| Direct Time | 5-ten working days |

| Samples | Welcome |

| Shipping expression | By DHL,UPS,TNT,FedEx,EMS,By CZPT,By Air |

| Creation Ability | Car-lathe turning:ODΦ0.five-20mm,Tol.±0.01mm |

| CNC lathe turning:ODΦ0.five-250mm,Tol.±0.005mm | |

| CNC Milling:800x600mm(LxW),Tol.±0.05mm | |

| Grinding:Tol.±0.002mm | |

| CZPT heading & rolling:Metric .eight-M6,Unified Imperial#-1/4” | |

| Stamping:200T max |

Business Data:

Launched day: Established in 2016, and have six a long time encounters in spring generation

Enterprise Kind: Maker

Business Assortment: Tools&CZPT

Major Merchandise: brass insert,CZPT, Elastic mobile

Management Technique Certification: CZPT, TS16949, SGS

Factory

Gr65 Rotex Coupling Spiders for Shaft Connection, 134*69*25 Screw Portable Air Compressor Parts Rubber Coupling

GR65 CZPT coupling spiders for shaft relationship,134*69*twenty five

Framework: Spider Flexible or Rigid:Flexible

CZPT or Nonstandard:CZPT Material:PU, or other folks, PU

Brand Identify:Y&F Place of Origin:HangCZPT, China (Mainland)

Model Number:Elastic spider Merchandise:spider coupling rubber

Coloration:Red color Measurement:GR65

MOQ:10 Pcs, also depend on you needs Specification:134*sixty nine*25

Provide Capacity

Supply Capability:

3000 Piece/Pieces for every Thirty day period

Packaging & Supply

Packaging Specifics

In standard export packing:suche as carton, plastic luggage and so forth.

HangCZPT,China

Lead Time :

In 3-seven days or according to your orders

|

Spot of Origin |

HangCZPT, China (Mainland) |

|

Manufacturer Name |

YNF/Y&F |

|

Residence |

Large/reduced temperature resistance, oil and gas resistance, weathering resistance, O zone resistance and so on. |

|

Shape |

In accordance to your need. |

|

Coloration |

Red color |

|

Substance |

Jaw,Spider,Rubber |

|

Supply |

In 10 days after payment |

|

Packing |

CZPT bag & carton box or according to your requirements. |

|

Application |

Excavator/Digger |

Solution present as beneath:

|

OD |

ID | H | |

| GR-28 | sixty five | thirty | twenty |

| GR-38 | 80 | 38 | 22 |

| GR-42 | 95 | 45 | twenty |

| GR-forty eight | a hundred and five | fifty two | 26 |

| GR-fifty five | one hundred twenty | sixty | 27 |

| GR-sixty five | 134 | sixty nine | 25 |

| GR-75 | a hundred and sixty | eighty | 37 |

| GR-ninety | 199 | a hundred | 42 |

| GR-100 | 224 | 113 | 38 |

| GR-a hundred and ten | 225 | 127 | 42.five |

About us:

Organization Information

Yingfeng CZPT CZPT Minimal recognized in 1988,possessing the two investing firm and owned factory .Workplace and showroom are situated in HangCZPT ,Xihu (West Lake) Dis. district. We create and market different Excavator Areas,this kind of as coupling,Oil Seal,CZPT Areas,Excavator Rubber Components,Excavator CZPT Areas,Excavator putting on Elements,Motor Areas,Excavator Filters,Excavator Gears,CZPTs,Excavator A/C Components,Excavator Undercarriage Areas and Some CZPT couplings.

The components we supplly can be used brandbexcavators:CZPT,CZPT,Sumitomo,Hyundai,CZPT,Case,Liebherr,CZPT,Kato,Sany,Lonking,Sunward,CZPT,Samsung,Daewoo,CZPT,Volvo,CZPT,Isuzu,Yanmar,Kawasaki and Mitsubishi and so on.

FAQ

Gr65 Rotex Coupling Spiders for Shaft Connection, 134*69*25 Screw Portable Air Compressor Parts Rubber Coupling

Gr65 CZPT Coupling Spiders for Shaft Connection, 134*69*twenty five

Construction:Jaw / Spider Flexible or Rigid:Versatile

CZPT or Nonstandard:CZPT Material:PU, or others, PU

Brand Name:Y&F Place of Origin:HangCZPT, China (Mainland)

Product Amount:Elastic spider Item:spider coupling rubber

Colour:Red color Measurement:GR65

MOQ:one Pcs, also count on you needs Specification:134*sixty nine*twenty five

Provide Capacity

Offer Capacity:

3000 Piece/Pieces for each Month

Packaging & Shipping

Packaging Details

In common export packing:suche as carton, plastic baggage etc.

HangCZPT,China

Guide Time :

In 3-7 times or in accordance to your orders

|

Area of Origin |

HangCZPT, China (Mainland) |

|

Brand Name |

YNF/Y&F |

|

Home |

Substantial/low temperature resistance, oil and fuel resistance, weathering resistance, O zone resistance etc. |

|

Form |

According to your need. |

|

Color |

Red color |

|

Content |

Jaw,Spider,Rubber |

|

Supply |

In ten times right after payment |

|

Packing |

CZPT bag & carton box or according to your requirements. |

|

Software |

Excavator/Digger |

Product show as underneath:

|

OD |

ID | H | |

| GR-28 | 65 | thirty | twenty |

| GR-38 | eighty | 38 | 22 |

| GR-forty two | 95 | 45 | twenty |

| GR-forty eight | 105 | 52 | 26 |

| GR-fifty five | one hundred twenty | 60 | 27 |

| GR-65 | 134 | sixty nine | 25 |

| GR-75 | 160 | 80 | 37 |

| GR-ninety | 199 | one hundred | forty two |

| GR-a hundred | 224 | 113 | 38 |

| GR-110 | 225 | 127 | forty two.five |

About us:

Business Info

Yingfeng CZPT CZPT Minimal set up in 1988,having both investing company and owned factory .Place of work and showroom are found in HangCZPT ,Xihu (West Lake) Dis. district. We produce and sell different Excavator Parts,this kind of as coupling,Oil Seal,CZPT Parts,Excavator Rubber Areas,Excavator CZPT Components,Excavator donning Areas,Engine Elements,Excavator Filters,Excavator Gears,CZPTs,Excavator A/C Parts,Excavator Undercarriage Elements and Some CZPT couplings.

The elements we supplly can be utilised brandbexcavators:CZPT,CZPT,Sumitomo,Hyundai,CZPT,Case,Liebherr,CZPT,Kato,Sany,Lonking,Sunward,CZPT,Samsung,Daewoo,CZPT,Volvo,CZPT,Isuzu,Yanmar,Kawasaki and Mitsubishi etc.

FAQ

Ball Screw Shaft Coupling, Flexible Shaft Coupling for Motor, Plum Coupling

Producs description:

1.Content: PU

2. Hardness: Durometer 70-90 Shore A

three.Coloration: red,black,yellow

four.Brand & Printing: according to your ask for.

5.Application: Car Digital merchandise, CZPT and so on

Plum blossom mat, entire identify plum-shaped elastic coupling cushion. It is utilized for cushioning of numerous large machinery coupling shafts. Some places are also recognized as plum blossom plates. In accordance to the material, it can be divided into polyurethane plum mat and rubber plum mat, nylon plum mat.

Plum blossom mat is divided into MT sort plum blossom mat, T-formed hexagonal mat, GR star plum blossom mat, HRC hexagonal mat, NM kind elastic ring, L-shaped hexagonal pad, NL nylon interior tooth sleeve, H-sort elastic block, rubber gear, and many others.

The plum blossom pad is used for damping, insulation and buffer transmission torque in the center of the coupling. The torque transmitted by the plum blossom pads of various materials and different hardness is also different. The larger the hardness, the greater the torque transmitted

packing and delivery

packing: carton box and pallet.

shipping: according to your quantity, generally five-30 days after your payment.

Company Brief Introduction:

SHEN ZHOU AOKAI RUBBER & CZPT CO.,LTD was founded in 2000. The factory located in industrial zone of HangCZPT city, ZheCZPT province, china.

We have CZPT injection molding workshop and rubber compression molding workshops.

Our main products includes Bakelit Knobs,Pull Handle,rubber door stops, door guard, roller, rubber bumpers, Rubber grommets, vibration dampers, seals, plastic corner, injection plastic brackets, injection plastic shell.

to undertake various kinds of rubber molding and plastic injection parts, customize according to drawing and samples.

The products have been exported to CZPTica, CZPTpe, CZPTia, Middle CZPT, Southeast Asia and other regions and countries, and hope to build more business Cooperation with new client from all over the world.

Why select us?

1.Our business was established in 2000, have rich experience in production.

two.Solution from purchased supplies, processing, assembly, have strict top quality handle.

three.We have our personal creation plant, products more cheaper.

four.The business has specialized production lines and perfect screening facilities.

5. Our services formulation: Good good quality,cheap price and good service.